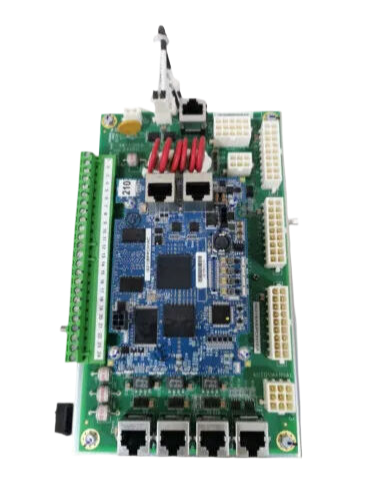

GE INTELLIX MO150 Process Control Module

Introducing the GE INTELLIX, the latest innovation from GE designed to elevate your automation capabilities with unparalleled efficiency and reliability. This advanced product stands at the forefront of GE automation products, ideal for a wide range of industrial applications.

Key Technical Features

The GE INTELLIX boasts a robust architecture that integrates seamlessly into existing systems, ensuring smooth operations across diverse environments. With a high processing speed, it delivers quick response times, optimizing performance in real-time applications. The unit is equipped with advanced diagnostics that enhance troubleshooting, reducing downtime and maintenance costs. Additionally, the GE INTELLIX features extensive connectivity options, allowing it to communicate effortlessly with various devices and systems, including other GE automation products. Its modular design provides flexibility for future expansions or upgrades, making it a future-proof solution for evolving industrial needs.

Usage Scenarios

The GE INTELLIX is designed for versatility, making it suitable for various industries, including manufacturing, oil and gas, water treatment, and food production. In a manufacturing setting, it can streamline production lines by improving communication between machines, thereby increasing throughput and reducing errors. In the oil and gas sector, its robust diagnostics can monitor critical systems, ensuring safety and compliance with industry regulations. For water treatment facilities, the GE INTELLIX can automate control processes, enhancing water quality management while minimizing operational costs. Its adaptability allows it to serve as an integral part of any automation strategy, regardless of the industry.

Comparison with Other Models

When comparing the GE INTELLIX to other models in the GE product line, such as the GE IS200TBCIH1BBC and the GE IS220PPROS1B, it becomes clear that the INTELLIX offers superior processing capabilities and enhanced connectivity. While the IS200TBCIH1BBC excels in specific applications, the INTELLIX provides a broader range of functionalities suitable for complex, multi-faceted operations. Similarly, the GE CT7P70500470CW24 may perform well in standalone applications, but the INTELLIX’s integration capabilities allow it to function as a comprehensive solution across various systems, making it a more strategic choice for businesses looking to scale their automation efforts.

Reference to Related Models

For those considering the GE INTELLIX, it’s essential to understand its place within the broader GE ecosystem of automation products. Related models worth exploring include the GE IC697MDL250, known for its reliability in control applications, and the GE IS215UCVEH2AB, which offers advanced communication features. Additionally, the GE DS200CTBAG1ADD serves as a solid choice for users requiring robust control functionalities. The GE IS200TPROH1BBB and GE IC660ELB912G are also excellent alternatives for specialized applications, while the GE IS200DSPXH1DBC focuses on high-performance processing. The GE 531X307LTBAJG1 and GE DS200SDCCG1AGD are perfect for users seeking dependability in critical environments. Lastly, the GE IS220PRTDH1A stands out for temperature monitoring applications, reinforcing the extensive options available within the GE automation product lineup.

Conclusion

In summary, the GE INTELLIX is a groundbreaking solution that enhances operational efficiency and reliability across various industries. With its advanced technical features, versatility in usage scenarios, and superior integration capabilities compared to other models, it is an invaluable asset for any organization looking to improve its automation systems. By investing in the GE INTELLIX, you not only gain access to cutting-edge technology but also secure a future-ready solution designed to adapt to the ever-changing landscape of industrial automation. Embrace the future of automation with GE INTELLIX and unlock your operational potential today.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE INTELLIX boasts a robust architecture that integrates seamlessly into existing systems, ensuring smooth operations across diverse environments. With a high processing speed, it delivers quick response times, optimizing performance in real-time applications. The unit is equipped with advanced diagnostics that enhance troubleshooting, reducing downtime and maintenance costs. Additionally, the GE INTELLIX features extensive connectivity options, allowing it to communicate effortlessly with various devices and systems, including other GE automation products. Its modular design provides flexibility for future expansions or upgrades, making it a future-proof solution for evolving industrial needs.

Usage Scenarios

The GE INTELLIX is designed for versatility, making it suitable for various industries, including manufacturing, oil and gas, water treatment, and food production. In a manufacturing setting, it can streamline production lines by improving communication between machines, thereby increasing throughput and reducing errors. In the oil and gas sector, its robust diagnostics can monitor critical systems, ensuring safety and compliance with industry regulations. For water treatment facilities, the GE INTELLIX can automate control processes, enhancing water quality management while minimizing operational costs. Its adaptability allows it to serve as an integral part of any automation strategy, regardless of the industry.

Comparison with Other Models

When comparing the GE INTELLIX to other models in the GE product line, such as the GE IS200TBCIH1BBC and the GE IS220PPROS1B, it becomes clear that the INTELLIX offers superior processing capabilities and enhanced connectivity. While the IS200TBCIH1BBC excels in specific applications, the INTELLIX provides a broader range of functionalities suitable for complex, multi-faceted operations. Similarly, the GE CT7P70500470CW24 may perform well in standalone applications, but the INTELLIX’s integration capabilities allow it to function as a comprehensive solution across various systems, making it a more strategic choice for businesses looking to scale their automation efforts.

Reference to Related Models

For those considering the GE INTELLIX, it’s essential to understand its place within the broader GE ecosystem of automation products. Related models worth exploring include the GE IC697MDL250, known for its reliability in control applications, and the GE IS215UCVEH2AB, which offers advanced communication features. Additionally, the GE DS200CTBAG1ADD serves as a solid choice for users requiring robust control functionalities. The GE IS200TPROH1BBB and GE IC660ELB912G are also excellent alternatives for specialized applications, while the GE IS200DSPXH1DBC focuses on high-performance processing. The GE 531X307LTBAJG1 and GE DS200SDCCG1AGD are perfect for users seeking dependability in critical environments. Lastly, the GE IS220PRTDH1A stands out for temperature monitoring applications, reinforcing the extensive options available within the GE automation product lineup.

Conclusion

In summary, the GE INTELLIX is a groundbreaking solution that enhances operational efficiency and reliability across various industries. With its advanced technical features, versatility in usage scenarios, and superior integration capabilities compared to other models, it is an invaluable asset for any organization looking to improve its automation systems. By investing in the GE INTELLIX, you not only gain access to cutting-edge technology but also secure a future-ready solution designed to adapt to the ever-changing landscape of industrial automation. Embrace the future of automation with GE INTELLIX and unlock your operational potential today.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.