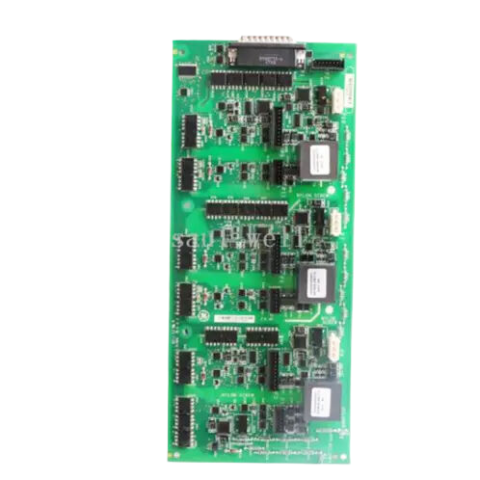

GE IC695CRU320 Controller Module

Introducing the GE IC695CRU320, a cutting-edge communication processor designed to enhance the performance of your automation systems. As part of GE's extensive lineup of reliable automation products, the IC695CRU320 offers advanced features that support seamless integration and enhanced connectivity for diverse industrial applications.

Key Technical Features

The GE IC695CRU320 boasts a powerful communication processor that supports numerous protocols, including Ethernet, making it an essential component for modern automation environments. With dual Ethernet ports, the IC695CRU320 enables high-speed communication and redundancy, ensuring that your system remains operational even in the event of a network failure. It also supports the GE Intelligent Platforms’ Proficy software suite, allowing for easy configuration and management of your automation system.

This communication processor features a robust architecture, designed to handle large volumes of data with minimal latency. The IC695CRU320 is equipped with a built-in web server, providing users with easy access to system information and diagnostics via a standard web browser. Additionally, it supports multiple protocols such as Modbus TCP/IP and DNP3, facilitating communication with a wide range of devices and systems.

Usage Scenarios

The GE IC695CRU320 is ideal for various industrial environments, including manufacturing, water treatment plants, and oil and gas operations. It can be utilized in applications where real-time data exchange is crucial, such as monitoring equipment status, controlling processes, and collecting data for analysis. This versatility makes it suitable for both small-scale operations and large, complex systems.

In manufacturing, for example, the IC695CRU320 can streamline communication between machines and supervisory control systems, enhancing overall production efficiency. In water treatment facilities, it can facilitate data collection from remote sensors to monitor water quality and ensure compliance with regulatory standards. The IC695CRU320 can also be employed in oil and gas operations for remote monitoring and control of pumps, compressors, and other critical equipment.

Comparison with Other Models

When compared to other models in the GE automation products lineup, the IC695CRU320 stands out for its advanced communication capabilities and ease of integration. For instance, when compared to the GE IC693CPU341, which is primarily a central processing unit, the IC695CRU320 offers enhanced networking capabilities, making it a better choice for applications requiring high-speed data transfer and communication with multiple devices.

Similarly, while the GE IS200TPROH1BCB provides reliable processing power, it lacks the dual Ethernet functionality found in the IC695CRU320, which is crucial for redundancy and fault tolerance. In contrast, models like the GE IC698CMX016 are designed for specific applications, but the IC695CRU320's versatility makes it suitable for a broader range of scenarios, establishing it as a go-to option for many automation needs.

Related Models

For those exploring the GE automation products range, several related models complement the IC695CRU320. These include the GE IS200TBCIH1BBC, which serves as a reliable terminal board, the GE IC670MDL740J for modular I/O applications, and the GE IC697MDL250 for digital input/output control. Additionally, the GE IS220PRTDH1A temperature input module and the GE 369-HI-0-M-0-0-0 multifunctional I/O module can be integrated with the IC695CRU320 for enhanced data acquisition capabilities.

For users seeking options within the same family, the GE IC693CPU374 and GE IC697ALG440 provide robust processing and analog input capabilities, respectively. The GE IS200PAICH2A and GE IS215UCVEH2AB also offer unique advantages for specific applications, while the GE DS200SDCCG1AGD serves as a dependable digital control card for critical processes.

In conclusion, the GE IC695CRU320 is a powerful communication processor that enhances the performance and reliability of your automation systems. With its advanced technical features, versatile usage scenarios, and competitive advantages over other models, it is an essential component for any modern industrial application. Explore the potential of GE automation products today and elevate your operational efficiency to new heights.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE IC695CRU320 boasts a powerful communication processor that supports numerous protocols, including Ethernet, making it an essential component for modern automation environments. With dual Ethernet ports, the IC695CRU320 enables high-speed communication and redundancy, ensuring that your system remains operational even in the event of a network failure. It also supports the GE Intelligent Platforms’ Proficy software suite, allowing for easy configuration and management of your automation system.

This communication processor features a robust architecture, designed to handle large volumes of data with minimal latency. The IC695CRU320 is equipped with a built-in web server, providing users with easy access to system information and diagnostics via a standard web browser. Additionally, it supports multiple protocols such as Modbus TCP/IP and DNP3, facilitating communication with a wide range of devices and systems.

Usage Scenarios

The GE IC695CRU320 is ideal for various industrial environments, including manufacturing, water treatment plants, and oil and gas operations. It can be utilized in applications where real-time data exchange is crucial, such as monitoring equipment status, controlling processes, and collecting data for analysis. This versatility makes it suitable for both small-scale operations and large, complex systems.

In manufacturing, for example, the IC695CRU320 can streamline communication between machines and supervisory control systems, enhancing overall production efficiency. In water treatment facilities, it can facilitate data collection from remote sensors to monitor water quality and ensure compliance with regulatory standards. The IC695CRU320 can also be employed in oil and gas operations for remote monitoring and control of pumps, compressors, and other critical equipment.

Comparison with Other Models

When compared to other models in the GE automation products lineup, the IC695CRU320 stands out for its advanced communication capabilities and ease of integration. For instance, when compared to the GE IC693CPU341, which is primarily a central processing unit, the IC695CRU320 offers enhanced networking capabilities, making it a better choice for applications requiring high-speed data transfer and communication with multiple devices.

Similarly, while the GE IS200TPROH1BCB provides reliable processing power, it lacks the dual Ethernet functionality found in the IC695CRU320, which is crucial for redundancy and fault tolerance. In contrast, models like the GE IC698CMX016 are designed for specific applications, but the IC695CRU320's versatility makes it suitable for a broader range of scenarios, establishing it as a go-to option for many automation needs.

Related Models

For those exploring the GE automation products range, several related models complement the IC695CRU320. These include the GE IS200TBCIH1BBC, which serves as a reliable terminal board, the GE IC670MDL740J for modular I/O applications, and the GE IC697MDL250 for digital input/output control. Additionally, the GE IS220PRTDH1A temperature input module and the GE 369-HI-0-M-0-0-0 multifunctional I/O module can be integrated with the IC695CRU320 for enhanced data acquisition capabilities.

For users seeking options within the same family, the GE IC693CPU374 and GE IC697ALG440 provide robust processing and analog input capabilities, respectively. The GE IS200PAICH2A and GE IS215UCVEH2AB also offer unique advantages for specific applications, while the GE DS200SDCCG1AGD serves as a dependable digital control card for critical processes.

In conclusion, the GE IC695CRU320 is a powerful communication processor that enhances the performance and reliability of your automation systems. With its advanced technical features, versatile usage scenarios, and competitive advantages over other models, it is an essential component for any modern industrial application. Explore the potential of GE automation products today and elevate your operational efficiency to new heights.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.