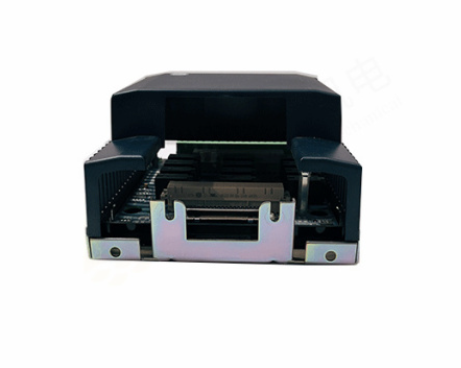

GE IC200MDL241 16-Point AC Input Module for Industrial Control Systems

Introducing the GE IC200MDL241, an exceptional addition to the lineup of GE automation products designed to enhance your industrial automation systems. With its robust features and reliable performance, the IC200MDL241 stands out in a competitive market, making it an ideal choice for engineers and technicians looking to optimize their operations.

Key Technical Features:

The GE IC200MDL241 is a versatile I/O module that integrates seamlessly into GE’s Series 90-30 PLC systems. It features 24 discrete input channels, each capable of handling a wide range of voltage levels, making it suitable for various applications. The module is designed with high-speed processing capabilities, ensuring rapid data acquisition and response times critical for real-time applications. Additionally, the IC200MDL241 is equipped with LED indicators for each input, providing immediate visual feedback for troubleshooting and diagnostics. Its compact design allows for easy installation in tight spaces, and its robust construction ensures durability in demanding environments.

Usage Scenarios:

The GE IC200MDL241 is perfect for applications requiring reliable digital input management in sectors such as manufacturing, water treatment, and energy management. Whether you are controlling machinery, monitoring sensors, or integrating with other automation devices, this I/O module provides the necessary functionality to streamline operations. For example, in a manufacturing plant, the IC200MDL241 can be used to monitor the status of machinery, ensuring that operators have real-time information for better decision-making. Similarly, in water treatment facilities, it can assist in monitoring flow rates and pump statuses, ensuring efficient resource management.

Comparison with Other Models:

When comparing the GE IC200MDL241 to other models in the GE automation products range, such as the GE IC697MDL740 and GE IC200UAL005, the IC200MDL241 offers a balance of performance and versatility. While the IC697MDL740 provides advanced features for larger systems, the IC200MDL241 is tailored for smaller, more flexible applications. Meanwhile, the IC200UAL005 serves as a universal input/output module but lacks the specific high-speed capabilities of the IC200MDL241. This makes the IC200MDL241 a more suitable choice for applications where speed and reliability are paramount.

Related Models:

Understanding the landscape of GE automation products can further enhance your selection process. The GE SR750, GE IS200DSPXH2DBD, GE IC660BBA020, and GE DS200DDTBG2A are all noteworthy alternatives that cater to various needs in the industrial sector. The GE IS200VTURH1BAC offers advanced control features, whereas the GE IC200CPU005 serves as a versatile central processing unit for the Series 90-30. If your application requires specialized functions, consider the GE IS220PPDAH1A or the GE IC695CPE310-ABAH, both of which provide unique integration capabilities. For high-performance applications, models like the GE DS3800HSAB and GE DS200SVAAG1

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE IC200MDL241 is a versatile I/O module that integrates seamlessly into GE’s Series 90-30 PLC systems. It features 24 discrete input channels, each capable of handling a wide range of voltage levels, making it suitable for various applications. The module is designed with high-speed processing capabilities, ensuring rapid data acquisition and response times critical for real-time applications. Additionally, the IC200MDL241 is equipped with LED indicators for each input, providing immediate visual feedback for troubleshooting and diagnostics. Its compact design allows for easy installation in tight spaces, and its robust construction ensures durability in demanding environments.

Usage Scenarios:

The GE IC200MDL241 is perfect for applications requiring reliable digital input management in sectors such as manufacturing, water treatment, and energy management. Whether you are controlling machinery, monitoring sensors, or integrating with other automation devices, this I/O module provides the necessary functionality to streamline operations. For example, in a manufacturing plant, the IC200MDL241 can be used to monitor the status of machinery, ensuring that operators have real-time information for better decision-making. Similarly, in water treatment facilities, it can assist in monitoring flow rates and pump statuses, ensuring efficient resource management.

Comparison with Other Models:

When comparing the GE IC200MDL241 to other models in the GE automation products range, such as the GE IC697MDL740 and GE IC200UAL005, the IC200MDL241 offers a balance of performance and versatility. While the IC697MDL740 provides advanced features for larger systems, the IC200MDL241 is tailored for smaller, more flexible applications. Meanwhile, the IC200UAL005 serves as a universal input/output module but lacks the specific high-speed capabilities of the IC200MDL241. This makes the IC200MDL241 a more suitable choice for applications where speed and reliability are paramount.

Related Models:

Understanding the landscape of GE automation products can further enhance your selection process. The GE SR750, GE IS200DSPXH2DBD, GE IC660BBA020, and GE DS200DDTBG2A are all noteworthy alternatives that cater to various needs in the industrial sector. The GE IS200VTURH1BAC offers advanced control features, whereas the GE IC200CPU005 serves as a versatile central processing unit for the Series 90-30. If your application requires specialized functions, consider the GE IS220PPDAH1A or the GE IC695CPE310-ABAH, both of which provide unique integration capabilities. For high-performance applications, models like the GE DS3800HSAB and GE DS200SVAAG1

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.