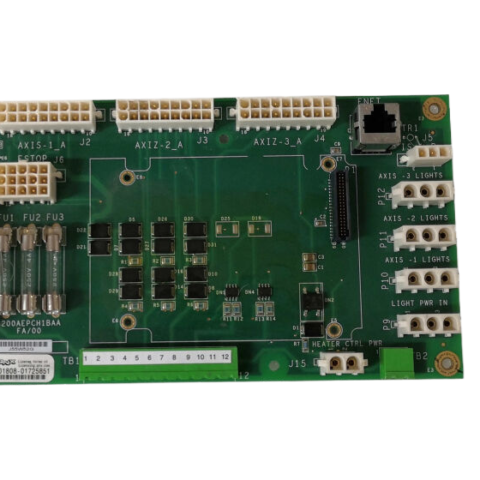

GE Fanuc VMIVME 6015 I/O Board

Introducing the GE Fanuc, a flagship model under the renowned GE brand, designed to deliver unparalleled performance and reliability in the world of automation and control systems. The GE Fanuc stands out in its category with advanced technical features that cater to a wide range of industrial applications, making it a preferred choice for engineers and automation specialists alike.

**Key Technical Features:**

The GE Fanuc boasts an impressive array of features tailored for seamless integration into various automation environments. Its robust architecture supports high-speed processing and extensive input/output capabilities, ensuring efficient operation in demanding settings. Key specifications include:

– **High Processing Speed:** The GE Fanuc is equipped with a powerful processor that enables rapid data processing and real-time decision-making, crucial for time-sensitive applications.

– **Flexible I/O Configuration:** With a versatile I/O architecture, the GE Fanuc allows for easy customization and scaling, accommodating a variety of sensors, actuators, and other devices.

– **Enhanced Communication Protocols:** This model supports multiple communication protocols, ensuring compatibility with other GE automation products as well as third-party devices.

– **User-Friendly Interface:** The intuitive interface simplifies programming and monitoring, allowing users to quickly adapt to the system without extensive training.

– **Robust Build Quality:** Designed for industrial environments, the GE Fanuc features a rugged design that withstands harsh conditions, including temperature fluctuations and dust.

**Usage Scenarios:**

The GE Fanuc is ideal for a multitude of applications across various sectors. It is commonly utilized in manufacturing, where it can manage assembly lines, monitor machinery, and optimize production processes. In energy management, the GE Fanuc helps control and automate the distribution of power, ensuring efficiency and reliability in service delivery. Additionally, its flexibility makes it suitable for building automation, where it can regulate HVAC systems, lighting, and security measures.

In the automotive industry, the GE Fanuc excels in coordinating robotic arms and conveyor systems, leading to enhanced productivity and precision. Likewise, in the food and beverage sector, it plays a critical role in process control, ensuring compliance with health and safety standards.

**Comparison with Other Models:**

When compared to other GE models, such as the GE SR750 and the GE IC697MDL740, the GE Fanuc stands out due to its superior processing capabilities and communication flexibility. While the SR750 serves well for basic control tasks, the Fanuc offers advanced functionalities that support complex automation solutions. Compared to the IS200DSFCG1AEB, which is tailored more towards specific applications, the GE Fanuc’s versatility makes it a go-to choice for diverse industrial needs.

The GE IS200DSPXH2DBD and GE IC693APU301 are also notable mentions within the GE range; however, they tend to focus on specific control functions, whereas the GE Fanuc provides a comprehensive solution that bridges various automation requirements. The GE IC695CPE310-ABAH is another competitive model, yet it lacks the extensive I/O options found in the Fanuc

The above parameters are for reference only. Please contact our technical team for precise selection.

**Key Technical Features:**

The GE Fanuc boasts an impressive array of features tailored for seamless integration into various automation environments. Its robust architecture supports high-speed processing and extensive input/output capabilities, ensuring efficient operation in demanding settings. Key specifications include:

– **High Processing Speed:** The GE Fanuc is equipped with a powerful processor that enables rapid data processing and real-time decision-making, crucial for time-sensitive applications.

– **Flexible I/O Configuration:** With a versatile I/O architecture, the GE Fanuc allows for easy customization and scaling, accommodating a variety of sensors, actuators, and other devices.

– **Enhanced Communication Protocols:** This model supports multiple communication protocols, ensuring compatibility with other GE automation products as well as third-party devices.

– **User-Friendly Interface:** The intuitive interface simplifies programming and monitoring, allowing users to quickly adapt to the system without extensive training.

– **Robust Build Quality:** Designed for industrial environments, the GE Fanuc features a rugged design that withstands harsh conditions, including temperature fluctuations and dust.

**Usage Scenarios:**

The GE Fanuc is ideal for a multitude of applications across various sectors. It is commonly utilized in manufacturing, where it can manage assembly lines, monitor machinery, and optimize production processes. In energy management, the GE Fanuc helps control and automate the distribution of power, ensuring efficiency and reliability in service delivery. Additionally, its flexibility makes it suitable for building automation, where it can regulate HVAC systems, lighting, and security measures.

In the automotive industry, the GE Fanuc excels in coordinating robotic arms and conveyor systems, leading to enhanced productivity and precision. Likewise, in the food and beverage sector, it plays a critical role in process control, ensuring compliance with health and safety standards.

**Comparison with Other Models:**

When compared to other GE models, such as the GE SR750 and the GE IC697MDL740, the GE Fanuc stands out due to its superior processing capabilities and communication flexibility. While the SR750 serves well for basic control tasks, the Fanuc offers advanced functionalities that support complex automation solutions. Compared to the IS200DSFCG1AEB, which is tailored more towards specific applications, the GE Fanuc’s versatility makes it a go-to choice for diverse industrial needs.

The GE IS200DSPXH2DBD and GE IC693APU301 are also notable mentions within the GE range; however, they tend to focus on specific control functions, whereas the GE Fanuc provides a comprehensive solution that bridges various automation requirements. The GE IC695CPE310-ABAH is another competitive model, yet it lacks the extensive I/O options found in the Fanuc

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.