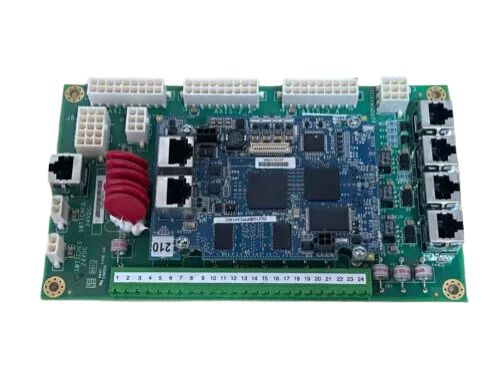

GE Fanuc IS220PAOCH1B Advanced Gas Turbine Control Systems

Introducing the GE Fanuc, a powerhouse in the realm of industrial automation and control systems. Renowned for their reliability and precision, GE Fanuc products offer advanced features tailored for a variety of applications, ensuring that your operations run smoothly and efficiently.

Key Technical Features:

The GE Fanuc model is engineered with cutting-edge technology designed to enhance performance in industrial settings. Its core features include high-speed processing capabilities, robust communication interfaces, and exceptional scalability. With the ability to seamlessly integrate with a variety of GE automation products, the GE Fanuc model supports multiple protocols, ensuring compatibility with existing systems while providing flexibility for future upgrades. Additionally, its user-friendly interface simplifies programming and monitoring, allowing operators to focus on productivity rather than troubleshooting.

The GE Fanuc also boasts advanced diagnostic tools, which facilitate proactive maintenance and minimize downtime. Built with a rugged design, this model can withstand harsh environments, making it ideal for manufacturing facilities, power plants, and other industrial applications. The system's modular architecture allows for easy expansion, accommodating the growing needs of your operation without requiring a complete overhaul of your existing infrastructure.

Usage Scenarios:

The GE Fanuc is perfect for a wide range of industrial applications. In manufacturing, it can control complex machinery and automate production lines, optimizing efficiency and reducing labor costs. In the energy sector, this model can monitor and control power generation systems, ensuring reliable energy distribution while maintaining safety standards. Furthermore, the GE Fanuc is suitable for water and wastewater management, where it can automate processes and monitor systems for compliance with environmental regulations.

In the automotive industry, the GE Fanuc excels in assembly line automation, enabling real-time monitoring and control of manufacturing processes. Its versatility also extends to the food and beverage sector, where it can manage production lines while adhering to strict hygiene standards. With its ability to connect to IoT devices, the GE Fanuc can facilitate smart factory initiatives, enhancing data collection and analysis for improved decision-making.

Comparison with Other Models:

When compared to other models within the GE range, such as the GE SR750 and GE IC697MDL740, the GE Fanuc stands out due to its superior processing speed and enhanced communication capabilities. While the GE SR750 is designed for specific applications, the GE Fanuc offers broader compatibility with various systems, making it a more versatile choice for diverse industrial environments.

Similarly, while the GE IS200DSPXH2DBD focuses on specific control functions, the GE Fanuc provides a comprehensive solution that caters to multiple needs, ensuring that it can adapt as your business evolves. The GE IC200CPU005, while reliable, may not offer the same level of advanced features and scalability that the GE Fanuc does, making it a less favorable option for companies looking to future-proof their automation systems.

Related Models:

For those exploring the GE automation products portfolio, consider the following related models: GE IC660BBA020, GE IS200DSFCG1AEB, GE IS220PPDAH1A, GE IS

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE Fanuc model is engineered with cutting-edge technology designed to enhance performance in industrial settings. Its core features include high-speed processing capabilities, robust communication interfaces, and exceptional scalability. With the ability to seamlessly integrate with a variety of GE automation products, the GE Fanuc model supports multiple protocols, ensuring compatibility with existing systems while providing flexibility for future upgrades. Additionally, its user-friendly interface simplifies programming and monitoring, allowing operators to focus on productivity rather than troubleshooting.

The GE Fanuc also boasts advanced diagnostic tools, which facilitate proactive maintenance and minimize downtime. Built with a rugged design, this model can withstand harsh environments, making it ideal for manufacturing facilities, power plants, and other industrial applications. The system's modular architecture allows for easy expansion, accommodating the growing needs of your operation without requiring a complete overhaul of your existing infrastructure.

Usage Scenarios:

The GE Fanuc is perfect for a wide range of industrial applications. In manufacturing, it can control complex machinery and automate production lines, optimizing efficiency and reducing labor costs. In the energy sector, this model can monitor and control power generation systems, ensuring reliable energy distribution while maintaining safety standards. Furthermore, the GE Fanuc is suitable for water and wastewater management, where it can automate processes and monitor systems for compliance with environmental regulations.

In the automotive industry, the GE Fanuc excels in assembly line automation, enabling real-time monitoring and control of manufacturing processes. Its versatility also extends to the food and beverage sector, where it can manage production lines while adhering to strict hygiene standards. With its ability to connect to IoT devices, the GE Fanuc can facilitate smart factory initiatives, enhancing data collection and analysis for improved decision-making.

Comparison with Other Models:

When compared to other models within the GE range, such as the GE SR750 and GE IC697MDL740, the GE Fanuc stands out due to its superior processing speed and enhanced communication capabilities. While the GE SR750 is designed for specific applications, the GE Fanuc offers broader compatibility with various systems, making it a more versatile choice for diverse industrial environments.

Similarly, while the GE IS200DSPXH2DBD focuses on specific control functions, the GE Fanuc provides a comprehensive solution that caters to multiple needs, ensuring that it can adapt as your business evolves. The GE IC200CPU005, while reliable, may not offer the same level of advanced features and scalability that the GE Fanuc does, making it a less favorable option for companies looking to future-proof their automation systems.

Related Models:

For those exploring the GE automation products portfolio, consider the following related models: GE IC660BBA020, GE IS200DSFCG1AEB, GE IS220PPDAH1A, GE IS

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.