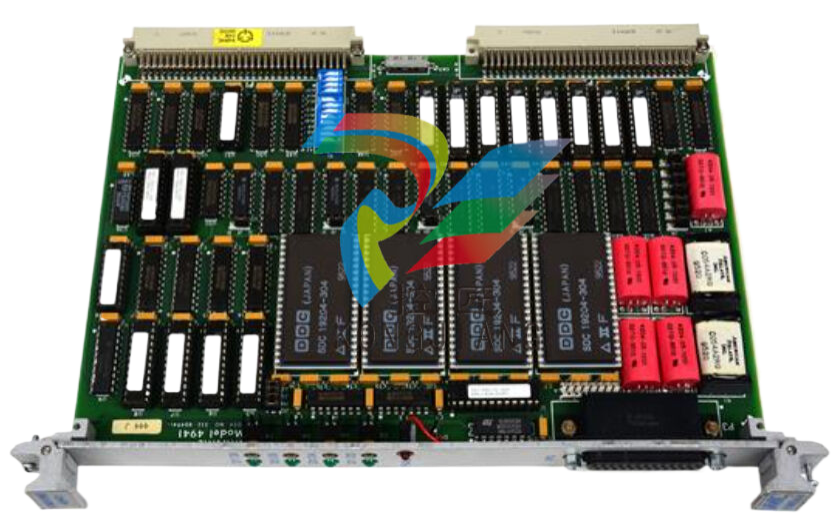

GE FANUC Industrial Control Module IC695NIU001DN

Introducing the GE FANUC, a premier model in GE’s extensive lineup of automation products that combines cutting-edge technology, robust performance, and unparalleled reliability. Designed to meet the demands of modern industrial applications, the GE FANUC is engineered for versatility and efficiency, making it an indispensable asset for businesses striving for operational excellence.

Key Technical Features:

The GE FANUC is packed with advanced features that set it apart in the automation landscape. With an impressive processing speed, it ensures rapid data handling and real-time decision-making, which is crucial for high-speed manufacturing environments. The model supports a wide range of communication protocols, enabling seamless integration with various industrial systems. Additionally, the GE FANUC boasts enhanced diagnostic capabilities, allowing users to quickly identify and troubleshoot issues. This model is designed with a rugged enclosure that withstands extreme temperatures and harsh environments, ensuring longevity and reliability. The user-friendly interface simplifies programming and operation, making it accessible for both seasoned professionals and newcomers to the field.

Usage Scenarios:

The versatility of the GE FANUC makes it suitable for a myriad of applications across different industries. In manufacturing, it excels in controlling complex machinery and automating assembly lines, enhancing productivity and precision. In the energy sector, the GE FANUC is utilized for monitoring and controlling power generation systems, ensuring optimal performance and safety. Additionally, its capabilities extend to the transportation industry, where it can manage logistics and traffic systems efficiently. The adaptability of the GE FANUC allows it to be deployed in various environments, from factory floors to remote locations, making it an ideal choice for businesses looking to streamline operations and improve overall efficiency.

Comparison with Other Models:

When comparing the GE FANUC to other models within the GE brand, such as the GE SR750 and GE IC697MDL740, it stands out due to its balance of processing power and user-friendly design. While the GE SR750 offers advanced data processing capabilities, the GE FANUC provides a more intuitive interface, making it easier for operators to implement and manage. In contrast, the GE IS200DSFCG1AEB may excel in specific applications, but the GE FANUC delivers a more comprehensive solution for a variety of industrial needs. Overall, the GE FANUC is designed to bridge the gap between complexity and usability, making it a preferred choice among industry professionals.

Related Models:

The GE FANUC is part of a robust family of GE automation products, each tailored to meet specific operational requirements. Other models worth considering include the GE IS200DSPXH2DBD, known for its flexibility in control applications; the GE IC660BBA020, which is ideal for high-speed data communication; and the GE DS200DDTBG2A, designed for advanced motion control. The GE IC200CPU005 and GE IC695CPE310-ABAH models provide excellent processing capabilities, while the GE IS200EDFFH1ABA offers enhanced data handling features. For those seeking high reliability, the GE 469-P5-HI-A1-E

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE FANUC is packed with advanced features that set it apart in the automation landscape. With an impressive processing speed, it ensures rapid data handling and real-time decision-making, which is crucial for high-speed manufacturing environments. The model supports a wide range of communication protocols, enabling seamless integration with various industrial systems. Additionally, the GE FANUC boasts enhanced diagnostic capabilities, allowing users to quickly identify and troubleshoot issues. This model is designed with a rugged enclosure that withstands extreme temperatures and harsh environments, ensuring longevity and reliability. The user-friendly interface simplifies programming and operation, making it accessible for both seasoned professionals and newcomers to the field.

Usage Scenarios:

The versatility of the GE FANUC makes it suitable for a myriad of applications across different industries. In manufacturing, it excels in controlling complex machinery and automating assembly lines, enhancing productivity and precision. In the energy sector, the GE FANUC is utilized for monitoring and controlling power generation systems, ensuring optimal performance and safety. Additionally, its capabilities extend to the transportation industry, where it can manage logistics and traffic systems efficiently. The adaptability of the GE FANUC allows it to be deployed in various environments, from factory floors to remote locations, making it an ideal choice for businesses looking to streamline operations and improve overall efficiency.

Comparison with Other Models:

When comparing the GE FANUC to other models within the GE brand, such as the GE SR750 and GE IC697MDL740, it stands out due to its balance of processing power and user-friendly design. While the GE SR750 offers advanced data processing capabilities, the GE FANUC provides a more intuitive interface, making it easier for operators to implement and manage. In contrast, the GE IS200DSFCG1AEB may excel in specific applications, but the GE FANUC delivers a more comprehensive solution for a variety of industrial needs. Overall, the GE FANUC is designed to bridge the gap between complexity and usability, making it a preferred choice among industry professionals.

Related Models:

The GE FANUC is part of a robust family of GE automation products, each tailored to meet specific operational requirements. Other models worth considering include the GE IS200DSPXH2DBD, known for its flexibility in control applications; the GE IC660BBA020, which is ideal for high-speed data communication; and the GE DS200DDTBG2A, designed for advanced motion control. The GE IC200CPU005 and GE IC695CPE310-ABAH models provide excellent processing capabilities, while the GE IS200EDFFH1ABA offers enhanced data handling features. For those seeking high reliability, the GE 469-P5-HI-A1-E

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.