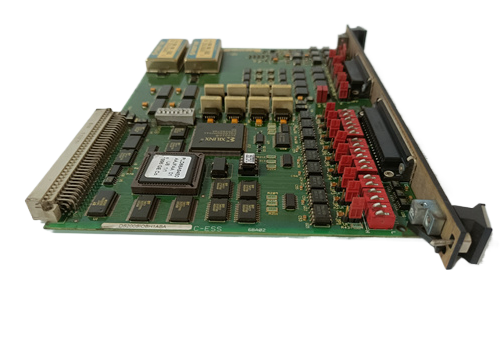

GE Fanuc IC695PMM335 Advanced PACMotion Multi-Axis Motion Controller

Introducing the GE Fanuc: The Pinnacle of Automation Reliability and Innovation

In the realm of industrial automation, the GE Fanuc model stands out as a beacon of advanced technology and reliability. Designed to meet the demands of modern manufacturing and process control environments, the GE Fanuc is engineered to provide robust performance, seamless integration, and unmatched versatility. This model is part of the extensive GE automation products portfolio, which has been a trusted name in the industry for decades.

Key Technical Features

The GE Fanuc boasts a range of impressive technical features designed to enhance operational efficiency and ensure longevity. With a powerful processing capability, it supports high-speed data collection and processing, making it ideal for real-time applications. The device offers multiple communication options, including Ethernet, RS-232, and RS-485, allowing for flexible connectivity with other GE automation products or third-party systems.

In addition to its robust processing capabilities, the GE Fanuc comes equipped with advanced diagnostic and monitoring tools that facilitate proactive maintenance and troubleshooting. Its modular architecture allows for easy scalability, enabling businesses to adapt to changing production needs without significant downtime. Furthermore, its compatibility with various GE components, such as the GE IC697MDL740 and GE IS200DSPXH2DBD, ensures that users can build a comprehensive automation system tailored to their specific requirements.

Usage Scenarios

The GE Fanuc is versatile enough to be utilized in a multitude of industrial applications. Whether it’s for discrete manufacturing, process control, or complex assembly lines, this model provides the reliability and efficiency needed to improve productivity. Industries such as automotive, food and beverage, pharmaceuticals, and energy can all benefit from integrating the GE Fanuc into their operations.

For example, in an automotive assembly line, the GE Fanuc can manage various robotic arms, coordinating their movements for precision assembly while monitoring quality control sensors to ensure that each component meets stringent industry standards. In a food processing plant, it can oversee temperature regulation systems, ensuring that products are stored and processed at optimal conditions.

Comparison with Other Models

When comparing the GE Fanuc with other models in the GE product line, such as the GE SR750 or the GE IS200DSFCG1AEB, it becomes evident that the GE Fanuc excels in terms of processing speed and connectivity options. While the GE SR750 is known for its reliability in rugged environments, the GE Fanuc offers a greater range of communication protocols, making it more adaptable for diverse applications.

In contrast, models like the GE IC693APU301 and GE IS220PPDAH1A provide excellent performance in specific tasks but may lack the comprehensive feature set that the GE Fanuc offers. The modular nature of the GE Fanuc also sets it apart from more fixed systems, allowing users to customize their setups based on evolving needs.

Related Models

For those considering the GE Fanuc, several related models can enhance and complement its functionality. These include the GE IC660BBA020, GE IS200DSPXH2DB

The above parameters are for reference only. Please contact our technical team for precise selection.

In the realm of industrial automation, the GE Fanuc model stands out as a beacon of advanced technology and reliability. Designed to meet the demands of modern manufacturing and process control environments, the GE Fanuc is engineered to provide robust performance, seamless integration, and unmatched versatility. This model is part of the extensive GE automation products portfolio, which has been a trusted name in the industry for decades.

Key Technical Features

The GE Fanuc boasts a range of impressive technical features designed to enhance operational efficiency and ensure longevity. With a powerful processing capability, it supports high-speed data collection and processing, making it ideal for real-time applications. The device offers multiple communication options, including Ethernet, RS-232, and RS-485, allowing for flexible connectivity with other GE automation products or third-party systems.

In addition to its robust processing capabilities, the GE Fanuc comes equipped with advanced diagnostic and monitoring tools that facilitate proactive maintenance and troubleshooting. Its modular architecture allows for easy scalability, enabling businesses to adapt to changing production needs without significant downtime. Furthermore, its compatibility with various GE components, such as the GE IC697MDL740 and GE IS200DSPXH2DBD, ensures that users can build a comprehensive automation system tailored to their specific requirements.

Usage Scenarios

The GE Fanuc is versatile enough to be utilized in a multitude of industrial applications. Whether it’s for discrete manufacturing, process control, or complex assembly lines, this model provides the reliability and efficiency needed to improve productivity. Industries such as automotive, food and beverage, pharmaceuticals, and energy can all benefit from integrating the GE Fanuc into their operations.

For example, in an automotive assembly line, the GE Fanuc can manage various robotic arms, coordinating their movements for precision assembly while monitoring quality control sensors to ensure that each component meets stringent industry standards. In a food processing plant, it can oversee temperature regulation systems, ensuring that products are stored and processed at optimal conditions.

Comparison with Other Models

When comparing the GE Fanuc with other models in the GE product line, such as the GE SR750 or the GE IS200DSFCG1AEB, it becomes evident that the GE Fanuc excels in terms of processing speed and connectivity options. While the GE SR750 is known for its reliability in rugged environments, the GE Fanuc offers a greater range of communication protocols, making it more adaptable for diverse applications.

In contrast, models like the GE IC693APU301 and GE IS220PPDAH1A provide excellent performance in specific tasks but may lack the comprehensive feature set that the GE Fanuc offers. The modular nature of the GE Fanuc also sets it apart from more fixed systems, allowing users to customize their setups based on evolving needs.

Related Models

For those considering the GE Fanuc, several related models can enhance and complement its functionality. These include the GE IC660BBA020, GE IS200DSPXH2DB

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.