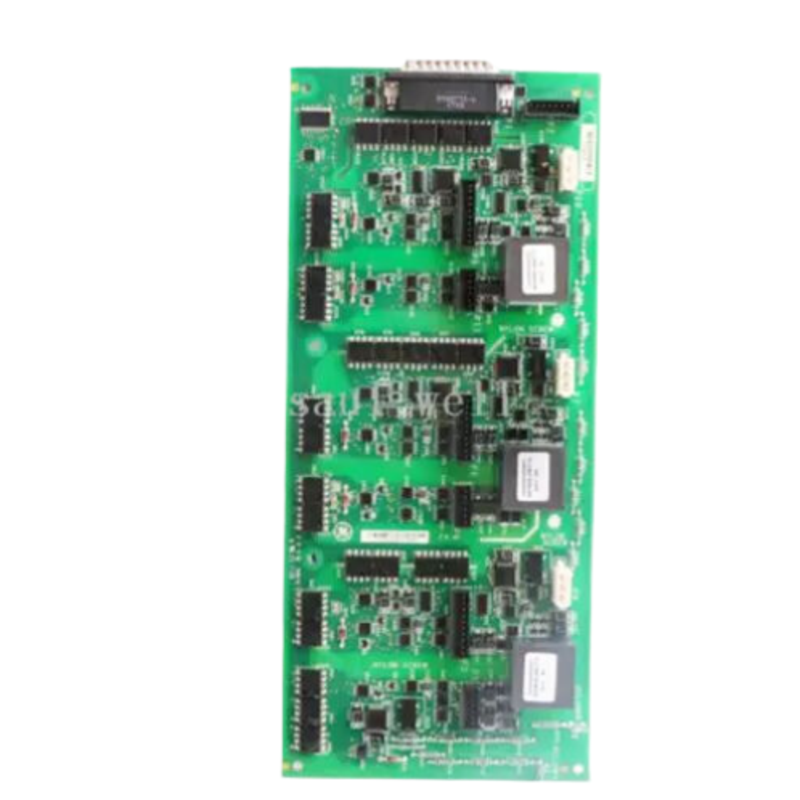

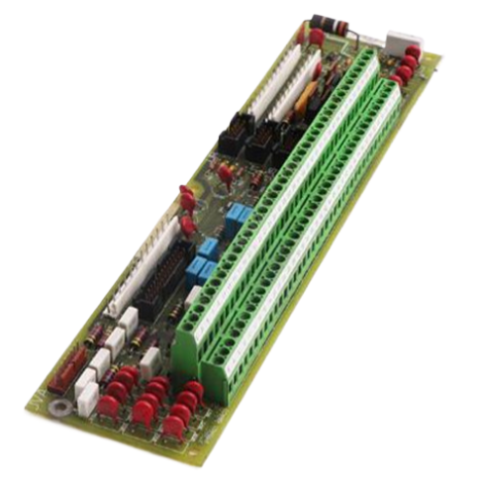

GE FANUC IC694MDL754CD Output Module Precision Control for Industrial Automation

Introducing the GE FANUC, a cornerstone in the realm of industrial automation and control systems. This advanced model is engineered to elevate operational efficiencies while ensuring unparalleled reliability in various industrial settings. With its robust architecture and innovative features, the GE FANUC stands out as a prime choice for enterprises seeking to optimize their automation processes.

Key Technical Features:

The GE FANUC is equipped with state-of-the-art technology that includes a high-performance processor, extensive memory capacity, and versatile I/O options. Its modular design allows for easy scalability, ensuring that businesses can adapt the system to meet evolving operational demands. Key features include seamless integration with other GE automation products, advanced diagnostics capabilities, and support for multiple communication protocols, enabling smooth interoperability with existing systems. Moreover, the GE FANUC is designed to withstand harsh industrial environments, with robust housing that protects against dust, moisture, and temperature fluctuations.

Usage Scenarios:

The adaptability of the GE FANUC makes it suitable for a wide range of applications. In manufacturing, it can be used for process control, machine automation, and robotics, driving significant productivity enhancements. In the energy sector, the GE FANUC excels in monitoring and controlling power generation and distribution systems, ensuring optimal performance and safety. Additionally, its capabilities extend to the transportation industry, where it can manage logistics, traffic control systems, and fleet management applications. This versatility allows businesses across various sectors to harness the power of GE FANUC to improve efficiency, reduce downtime, and increase profitability.

Comparison with Other Models:

When compared to other models within the GE lineup, such as the GE IS200TBCIH1BBC and GE IS220PPROS1B, the GE FANUC offers superior processing capabilities and a broader range of I/O options. While models like the GE IS215UCVEH2AB and GE IS200DSPXH1DBC are well-suited for specific applications, the GE FANUC’s modular design provides greater flexibility for users looking to expand their systems. Additionally, with its advanced diagnostics and troubleshooting features, the GE FANUC simplifies maintenance and reduces the likelihood of unexpected failures, a notable advantage over more traditional models.

Related Models:

For those considering the GE FANUC, there are several related models that can complement or serve as alternatives, including the GE IC697MDL250, GE IS220PAICH2A, GE IC660ELB912G, and GE IC693CPU341. Additionally, the GE DS200CTBAG1ADD and GE 369-HI-0-M-0-0-0 offer unique functionalities that may cater to specific industrial needs. Other noteworthy mentions are the GE IS230SNIDH1A, GE IS200EPSMG2ADC, and GE IC670MDL740J, each providing specialized capabilities that can enhance automation processes.

SEO Keywords:

As industries continue to shift towards automation, the demand for reliable solutions like the GE FANUC is on the rise. This model, along with other GE automation products, is designed to meet the challenges of modern manufacturing and process control. By integrating the GE FANUC into your operations, you can ensure that your business remains competitive in an ever-evolving landscape, leveraging the power of GE’s advanced automation technology.

In conclusion, the GE FANUC is not just a product; it’s a vital tool for any business looking to enhance operational efficiency, reliability, and adaptability. Whether you are in manufacturing, energy, transportation, or any other sector requiring advanced automation solutions, the GE FANUC is a trusted choice that promises to deliver exceptional performance and support your growth objectives. Experience the difference with GE automation products and elevate your automation strategy to new heights.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE FANUC is equipped with state-of-the-art technology that includes a high-performance processor, extensive memory capacity, and versatile I/O options. Its modular design allows for easy scalability, ensuring that businesses can adapt the system to meet evolving operational demands. Key features include seamless integration with other GE automation products, advanced diagnostics capabilities, and support for multiple communication protocols, enabling smooth interoperability with existing systems. Moreover, the GE FANUC is designed to withstand harsh industrial environments, with robust housing that protects against dust, moisture, and temperature fluctuations.

Usage Scenarios:

The adaptability of the GE FANUC makes it suitable for a wide range of applications. In manufacturing, it can be used for process control, machine automation, and robotics, driving significant productivity enhancements. In the energy sector, the GE FANUC excels in monitoring and controlling power generation and distribution systems, ensuring optimal performance and safety. Additionally, its capabilities extend to the transportation industry, where it can manage logistics, traffic control systems, and fleet management applications. This versatility allows businesses across various sectors to harness the power of GE FANUC to improve efficiency, reduce downtime, and increase profitability.

Comparison with Other Models:

When compared to other models within the GE lineup, such as the GE IS200TBCIH1BBC and GE IS220PPROS1B, the GE FANUC offers superior processing capabilities and a broader range of I/O options. While models like the GE IS215UCVEH2AB and GE IS200DSPXH1DBC are well-suited for specific applications, the GE FANUC’s modular design provides greater flexibility for users looking to expand their systems. Additionally, with its advanced diagnostics and troubleshooting features, the GE FANUC simplifies maintenance and reduces the likelihood of unexpected failures, a notable advantage over more traditional models.

Related Models:

For those considering the GE FANUC, there are several related models that can complement or serve as alternatives, including the GE IC697MDL250, GE IS220PAICH2A, GE IC660ELB912G, and GE IC693CPU341. Additionally, the GE DS200CTBAG1ADD and GE 369-HI-0-M-0-0-0 offer unique functionalities that may cater to specific industrial needs. Other noteworthy mentions are the GE IS230SNIDH1A, GE IS200EPSMG2ADC, and GE IC670MDL740J, each providing specialized capabilities that can enhance automation processes.

SEO Keywords:

As industries continue to shift towards automation, the demand for reliable solutions like the GE FANUC is on the rise. This model, along with other GE automation products, is designed to meet the challenges of modern manufacturing and process control. By integrating the GE FANUC into your operations, you can ensure that your business remains competitive in an ever-evolving landscape, leveraging the power of GE’s advanced automation technology.

In conclusion, the GE FANUC is not just a product; it’s a vital tool for any business looking to enhance operational efficiency, reliability, and adaptability. Whether you are in manufacturing, energy, transportation, or any other sector requiring advanced automation solutions, the GE FANUC is a trusted choice that promises to deliver exceptional performance and support your growth objectives. Experience the difference with GE automation products and elevate your automation strategy to new heights.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.