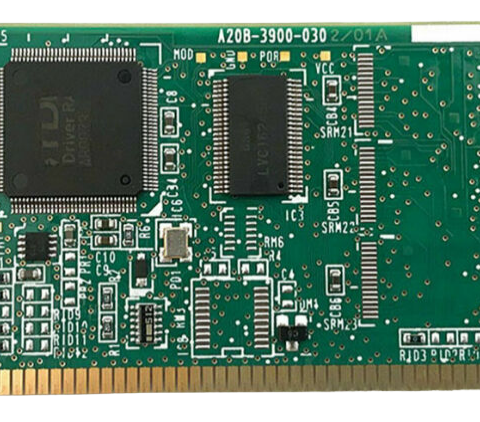

GE FANUC IC693PCM300 Advanced Process Control Coprocessor Module

Introducing the GE FANUC – a pinnacle of precision and reliability in the world of automation. Engineered with advanced technology, the GE FANUC is designed to elevate your industrial processes, making it an indispensable asset for any modern manufacturing environment. This product stands out in the GE automation products lineup, ensuring seamless integration and exceptional performance in various applications.

Key Technical Features:

The GE FANUC boasts an impressive array of technical features that cater to the diverse needs of industrial operations. With a powerful processing unit, it offers rapid computation capabilities, ensuring that even the most complex tasks are completed efficiently. Equipped with robust communication protocols, the GE FANUC can easily interface with other devices, such as sensors, drives, and HMIs, enabling a fully connected ecosystem. Its adaptability is further enhanced by modular design options, allowing for scalability and customization based on the specific requirements of your project. Additionally, the GE FANUC is known for its durability and resistance to harsh industrial environments, providing long-lasting performance with minimal downtime.

Usage Scenarios:

The versatility of the GE FANUC makes it suitable for various applications across multiple industries. Whether you're in automotive manufacturing, food processing, or pharmaceuticals, this automation solution is engineered to optimize productivity and improve operational efficiency. In automotive production lines, the GE FANUC can manage robotic arms for precise assembly tasks. In the food and beverage industry, it can monitor and control processes to ensure compliance with safety regulations. Furthermore, in pharmaceutical manufacturing, the GE FANUC can be used to maintain stringent quality control measures, ensuring that every batch meets industry standards.

Comparison with Other Models:

When compared to other models within the GE lineup, such as the GE SR750 or the GE IS200DSPXH2DBD, the GE FANUC excels in processing speed and communication capabilities. For example, while the GE SR750 is known for its advanced motion control, the GE FANUC offers enhanced connectivity with a broader range of devices, making it more versatile for complex automation tasks. Additionally, unlike the GE IS200DSFCG1AEB, which is tailored more specifically for particular applications, the GE FANUC’s modular design allows it to adapt to various functions, making it a more flexible choice for businesses looking to future-proof their operations.

Related Models:

For businesses exploring options within the GE automation products range, consider these related models: GE SR750, GE IC697MDL740, GE IS200DSFCG1AEB, GE IC660BBA020, GE DS200DDTBG2A, GE IS200DSPXH2DBD, GE IS220PPDAH1A, GE IS200EDFFH1ABA, GE IC200CPU005, and GE 469-P5-HI-A1-E-H. Each of these models comes with unique features tailored to specific needs, allowing businesses to find the perfect fit for their automation requirements.

Why Choose GE FANUC:

Investing in the GE FANUC means investing in cutting-edge technology

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE FANUC boasts an impressive array of technical features that cater to the diverse needs of industrial operations. With a powerful processing unit, it offers rapid computation capabilities, ensuring that even the most complex tasks are completed efficiently. Equipped with robust communication protocols, the GE FANUC can easily interface with other devices, such as sensors, drives, and HMIs, enabling a fully connected ecosystem. Its adaptability is further enhanced by modular design options, allowing for scalability and customization based on the specific requirements of your project. Additionally, the GE FANUC is known for its durability and resistance to harsh industrial environments, providing long-lasting performance with minimal downtime.

Usage Scenarios:

The versatility of the GE FANUC makes it suitable for various applications across multiple industries. Whether you're in automotive manufacturing, food processing, or pharmaceuticals, this automation solution is engineered to optimize productivity and improve operational efficiency. In automotive production lines, the GE FANUC can manage robotic arms for precise assembly tasks. In the food and beverage industry, it can monitor and control processes to ensure compliance with safety regulations. Furthermore, in pharmaceutical manufacturing, the GE FANUC can be used to maintain stringent quality control measures, ensuring that every batch meets industry standards.

Comparison with Other Models:

When compared to other models within the GE lineup, such as the GE SR750 or the GE IS200DSPXH2DBD, the GE FANUC excels in processing speed and communication capabilities. For example, while the GE SR750 is known for its advanced motion control, the GE FANUC offers enhanced connectivity with a broader range of devices, making it more versatile for complex automation tasks. Additionally, unlike the GE IS200DSFCG1AEB, which is tailored more specifically for particular applications, the GE FANUC’s modular design allows it to adapt to various functions, making it a more flexible choice for businesses looking to future-proof their operations.

Related Models:

For businesses exploring options within the GE automation products range, consider these related models: GE SR750, GE IC697MDL740, GE IS200DSFCG1AEB, GE IC660BBA020, GE DS200DDTBG2A, GE IS200DSPXH2DBD, GE IS220PPDAH1A, GE IS200EDFFH1ABA, GE IC200CPU005, and GE 469-P5-HI-A1-E-H. Each of these models comes with unique features tailored to specific needs, allowing businesses to find the perfect fit for their automation requirements.

Why Choose GE FANUC:

Investing in the GE FANUC means investing in cutting-edge technology

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.