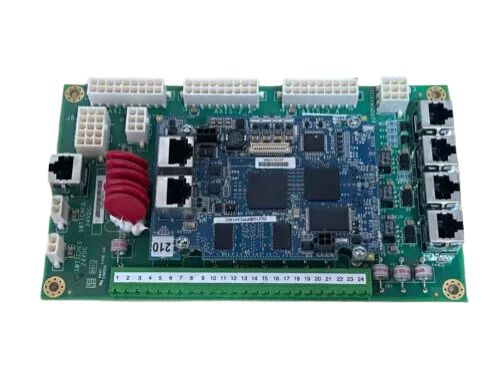

GE FANUC IC693CPU350 Programmable Logic Controller

Introducing the GE FANUC series, the pinnacle of industrial automation solutions designed to elevate your operational efficiency and reliability. Renowned for its robust engineering and cutting-edge technology, the GE FANUC line is an essential choice for a myriad of applications in manufacturing, process control, and discrete automation.

Key Technical Features:

The GE FANUC series boasts an array of advanced technical features that cater to the diverse needs of today’s industries. With high-performance processors and enhanced communication capabilities, these models ensure rapid data processing and seamless integration with existing systems. The modular design allows for easy scalability, making it simple to expand your automation capabilities as your business grows. Additionally, the GE FANUC products incorporate advanced diagnostic tools, which facilitate predictive maintenance and help reduce downtime, ultimately leading to greater productivity.

One of the standout features of the GE FANUC series is its compatibility with a wide range of I/O modules and field devices, enabling users to customize their automation setup according to their specific requirements. Furthermore, these products are equipped with robust cybersecurity measures, ensuring that your operations remain secure against potential threats.

Usage Scenarios:

The versatility of the GE FANUC series makes it suitable for various usage scenarios. In manufacturing environments, these automation products can streamline assembly lines, enhance quality control processes, and improve inventory management. In the energy sector, GE FANUC solutions can optimize the operation of power plants and renewable energy systems, driving efficiency and sustainability. Additionally, the series is well-suited for water treatment facilities, where precise control and monitoring are essential for maintaining operational standards.

Moreover, the GE FANUC models excel in the automotive industry, where they can be used to control robotic arms and automated guided vehicles (AGVs), ensuring precision and speed in manufacturing processes. The flexibility of these products also makes them ideal for food and beverage production, allowing for efficient handling and packaging of goods while adhering to strict safety regulations.

Comparison with Other Models:

When comparing the GE FANUC series to other models within the GE brand, such as the GE SR750 or the IC697MDL740, it becomes evident that the FANUC line offers superior processing power and advanced networking capabilities. While the SR750 is known for its reliability in control applications, the FANUC series stands out for its ability to handle complex automation tasks seamlessly. In contrast to the GE IS200DSPXH2DBD, which is tailored for specific applications, the GE FANUC series provides a broader range of functionalities, making it an ideal choice for diverse industrial needs.

For those seeking a balance between cost and performance, the GE IC660BBA020 presents a viable alternative; however, it lacks the advanced features and scalability options found in the GE FANUC series. Ultimately, businesses looking for a comprehensive automation solution should consider the GE FANUC models as the superior choice for enhancing operational efficiency across various sectors.

Related Models:

For those interested in exploring more of GE's impressive automation offerings, consider these related models: GE IS200EDFFH1ABA, GE IC200

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE FANUC series boasts an array of advanced technical features that cater to the diverse needs of today’s industries. With high-performance processors and enhanced communication capabilities, these models ensure rapid data processing and seamless integration with existing systems. The modular design allows for easy scalability, making it simple to expand your automation capabilities as your business grows. Additionally, the GE FANUC products incorporate advanced diagnostic tools, which facilitate predictive maintenance and help reduce downtime, ultimately leading to greater productivity.

One of the standout features of the GE FANUC series is its compatibility with a wide range of I/O modules and field devices, enabling users to customize their automation setup according to their specific requirements. Furthermore, these products are equipped with robust cybersecurity measures, ensuring that your operations remain secure against potential threats.

Usage Scenarios:

The versatility of the GE FANUC series makes it suitable for various usage scenarios. In manufacturing environments, these automation products can streamline assembly lines, enhance quality control processes, and improve inventory management. In the energy sector, GE FANUC solutions can optimize the operation of power plants and renewable energy systems, driving efficiency and sustainability. Additionally, the series is well-suited for water treatment facilities, where precise control and monitoring are essential for maintaining operational standards.

Moreover, the GE FANUC models excel in the automotive industry, where they can be used to control robotic arms and automated guided vehicles (AGVs), ensuring precision and speed in manufacturing processes. The flexibility of these products also makes them ideal for food and beverage production, allowing for efficient handling and packaging of goods while adhering to strict safety regulations.

Comparison with Other Models:

When comparing the GE FANUC series to other models within the GE brand, such as the GE SR750 or the IC697MDL740, it becomes evident that the FANUC line offers superior processing power and advanced networking capabilities. While the SR750 is known for its reliability in control applications, the FANUC series stands out for its ability to handle complex automation tasks seamlessly. In contrast to the GE IS200DSPXH2DBD, which is tailored for specific applications, the GE FANUC series provides a broader range of functionalities, making it an ideal choice for diverse industrial needs.

For those seeking a balance between cost and performance, the GE IC660BBA020 presents a viable alternative; however, it lacks the advanced features and scalability options found in the GE FANUC series. Ultimately, businesses looking for a comprehensive automation solution should consider the GE FANUC models as the superior choice for enhancing operational efficiency across various sectors.

Related Models:

For those interested in exploring more of GE's impressive automation offerings, consider these related models: GE IS200EDFFH1ABA, GE IC200

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.