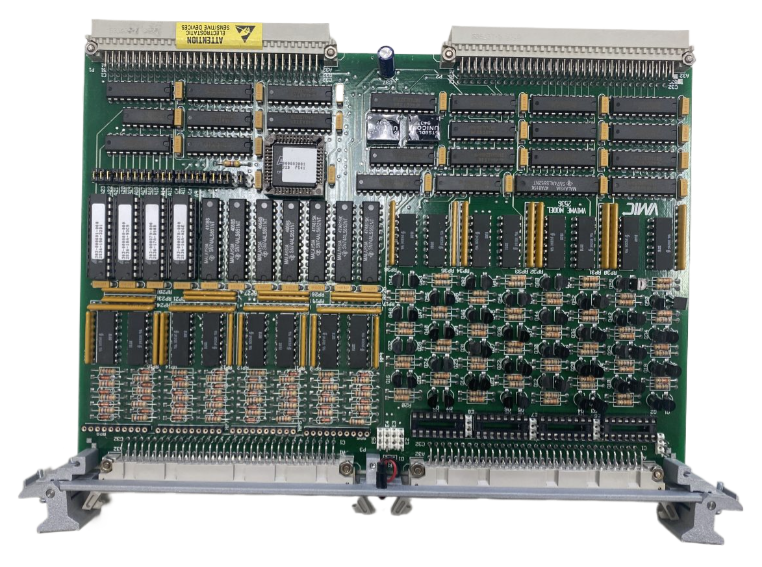

GE FANUC IC670MDL241 Input Module Advanced Field Control

Introducing the GE FANUC, a robust and versatile solution within the GE automation products lineup, designed to meet the demands of modern industrial applications. Renowned for its reliability and advanced capabilities, the GE FANUC is engineered to enhance operational efficiency, streamline processes, and ensure seamless integration into various industrial environments.

Key Technical Features

The GE FANUC boasts an array of cutting-edge features that set it apart from the competition. With a powerful processing unit, it delivers high-speed data processing and exceptional performance, making it suitable for complex automation tasks. The system supports multiple communication protocols, ensuring compatibility with a wide range of devices and networks, facilitating easy integration into existing infrastructures.

Equipped with a user-friendly interface, the GE FANUC simplifies programming and monitoring, allowing users to customize applications to their specific needs. The device also includes advanced diagnostic capabilities, enabling proactive maintenance and reducing downtime. With extensive memory capacity and robust storage options, it can handle large datasets and support extensive automation applications.

Usage Scenarios

The GE FANUC is ideal for a variety of industrial scenarios, including manufacturing, packaging, and process control. In manufacturing settings, it can orchestrate machinery, manage assembly lines, and optimize production workflows. For packaging applications, the GE FANUC enhances accuracy in labeling, packing, and sorting processes, ensuring high-quality output with minimal errors.

In process control environments, the GE FANUC excels at monitoring and regulating critical parameters, such as temperature, pressure, and flow rates. Its scalability allows it to adapt to small-scale operations or expansive industrial facilities, making it a versatile choice for businesses of all sizes. With the ability to integrate seamlessly with other GE automation products, the GE FANUC enhances overall system performance and reliability.

Comparison with Other Models

When comparing the GE FANUC to other models in the GE portfolio, such as the GE SR750 and GE IS200DSPXH2DBD, it becomes clear that the GE FANUC offers superior processing capabilities and advanced integration options. While the GE SR750 is designed for more specialized applications, the GE FANUC provides a comprehensive solution suitable for a wider range of industrial uses.

In contrast to the GE IC695CPE310-ABAH, which is optimized for specific control tasks, the GE FANUC's versatility allows it to handle complex automation challenges without compromising performance. Additionally, the GE IC200CPU005 and GE IS200TRPGH1BDE may focus on specific functions, whereas the GE FANUC stands out for its all-encompassing approach to automation and control.

Related Models

For those interested in exploring additional options within the GE automation products range, consider these related models: GE SR750, GE IC697MDL740, GE IS200DSFCG1AEB, GE IC660BBA020, GE DS200DDTBG2A, GE IS200DSPXH2DBD, GE ALG, GE IC693APU301, GE IS200JPDMG1ADC, and GE DS200SVA

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE FANUC boasts an array of cutting-edge features that set it apart from the competition. With a powerful processing unit, it delivers high-speed data processing and exceptional performance, making it suitable for complex automation tasks. The system supports multiple communication protocols, ensuring compatibility with a wide range of devices and networks, facilitating easy integration into existing infrastructures.

Equipped with a user-friendly interface, the GE FANUC simplifies programming and monitoring, allowing users to customize applications to their specific needs. The device also includes advanced diagnostic capabilities, enabling proactive maintenance and reducing downtime. With extensive memory capacity and robust storage options, it can handle large datasets and support extensive automation applications.

Usage Scenarios

The GE FANUC is ideal for a variety of industrial scenarios, including manufacturing, packaging, and process control. In manufacturing settings, it can orchestrate machinery, manage assembly lines, and optimize production workflows. For packaging applications, the GE FANUC enhances accuracy in labeling, packing, and sorting processes, ensuring high-quality output with minimal errors.

In process control environments, the GE FANUC excels at monitoring and regulating critical parameters, such as temperature, pressure, and flow rates. Its scalability allows it to adapt to small-scale operations or expansive industrial facilities, making it a versatile choice for businesses of all sizes. With the ability to integrate seamlessly with other GE automation products, the GE FANUC enhances overall system performance and reliability.

Comparison with Other Models

When comparing the GE FANUC to other models in the GE portfolio, such as the GE SR750 and GE IS200DSPXH2DBD, it becomes clear that the GE FANUC offers superior processing capabilities and advanced integration options. While the GE SR750 is designed for more specialized applications, the GE FANUC provides a comprehensive solution suitable for a wider range of industrial uses.

In contrast to the GE IC695CPE310-ABAH, which is optimized for specific control tasks, the GE FANUC's versatility allows it to handle complex automation challenges without compromising performance. Additionally, the GE IC200CPU005 and GE IS200TRPGH1BDE may focus on specific functions, whereas the GE FANUC stands out for its all-encompassing approach to automation and control.

Related Models

For those interested in exploring additional options within the GE automation products range, consider these related models: GE SR750, GE IC697MDL740, GE IS200DSFCG1AEB, GE IC660BBA020, GE DS200DDTBG2A, GE IS200DSPXH2DBD, GE ALG, GE IC693APU301, GE IS200JPDMG1ADC, and GE DS200SVA

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.