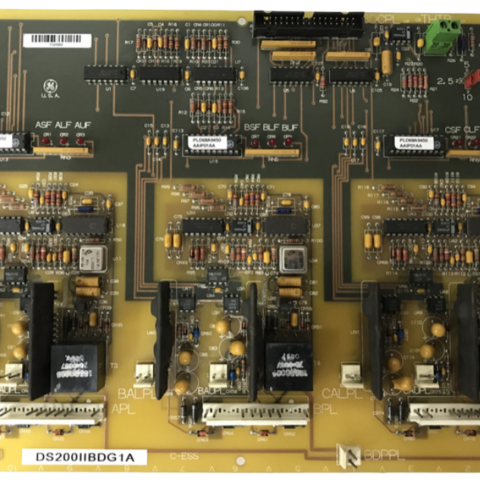

GE Fanuc IC200MDL650D Process Module Industrial Control Solution

Introducing the GE Fanuc series, a pinnacle of engineering excellence in the realm of industrial automation. GE Fanuc products are recognized globally for their reliability, versatility, and cutting-edge technology, making them a top choice for businesses seeking to enhance their operational efficiency. The GE Fanuc model delivers a robust suite of technical features designed to meet the demands of modern manufacturing environments.

Key Technical Features

The GE Fanuc model is designed with high-performance capabilities that stand out in the automation landscape. Key features include advanced processing power, which ensures rapid data handling and real-time analysis, enhancing productivity. The model supports a wide range of input and output configurations, allowing for seamless integration with existing systems and enabling flexibility in design. It is equipped with built-in communication protocols that facilitate connectivity with various devices, making it ideal for diverse automation tasks.

Additionally, the GE Fanuc model boasts an intuitive user interface, simplifying operation and programming. Users can benefit from extensive diagnostic tools, which provide real-time monitoring and troubleshooting, ensuring that any issues are identified and addressed swiftly. This model also adheres to stringent industry standards, ensuring safety and reliability in demanding environments.

Usage Scenarios

The versatility of the GE Fanuc model makes it suitable for a wide array of applications. In manufacturing, it is utilized for process control, machine automation, and assembly line management. The ability to integrate with sensors and actuators allows for precise control over machinery, optimizing production workflows. In the energy sector, GE automation products can be used for monitoring and controlling power systems, enhancing efficiency and reliability in energy distribution.

Moreover, the GE Fanuc model plays a significant role in the transportation industry, where it contributes to the automation of logistics and inventory management processes. Its robust communication features enable real-time tracking and data exchange, facilitating smarter decision-making.

Comparison with Other Models

When comparing the GE Fanuc model to other offerings within the GE portfolio, such as the GE SR750 or the GE IC697MDL740, the GE Fanuc model stands out due to its superior processing capabilities and enhanced connectivity options. While the GE SR750 is exceptional in its own right, particularly for its scalability, the GE Fanuc model offers a more compact solution without compromising on power.

In relation to the GE IS200DSPXH2DBD and GE IC660BBA020, the GE Fanuc model presents a more user-friendly interface, making it accessible for operators of varying experience levels. Furthermore, the GE Fanuc model is designed with future-proofing in mind, ensuring compatibility with emerging technologies in automation.

Related Models

For those interested in exploring the full range of GE automation products, consider the following related models: GE IS200EDFFH1ABA, GE IS200JPDMG1ADC, GE DS200DDTBG2A, GE IC693APU301, GE IC200CPU005, GE IC695CPE310-ABAH, GE IS200TRPGH1BDE, GE IC694PWR331, and

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE Fanuc model is designed with high-performance capabilities that stand out in the automation landscape. Key features include advanced processing power, which ensures rapid data handling and real-time analysis, enhancing productivity. The model supports a wide range of input and output configurations, allowing for seamless integration with existing systems and enabling flexibility in design. It is equipped with built-in communication protocols that facilitate connectivity with various devices, making it ideal for diverse automation tasks.

Additionally, the GE Fanuc model boasts an intuitive user interface, simplifying operation and programming. Users can benefit from extensive diagnostic tools, which provide real-time monitoring and troubleshooting, ensuring that any issues are identified and addressed swiftly. This model also adheres to stringent industry standards, ensuring safety and reliability in demanding environments.

Usage Scenarios

The versatility of the GE Fanuc model makes it suitable for a wide array of applications. In manufacturing, it is utilized for process control, machine automation, and assembly line management. The ability to integrate with sensors and actuators allows for precise control over machinery, optimizing production workflows. In the energy sector, GE automation products can be used for monitoring and controlling power systems, enhancing efficiency and reliability in energy distribution.

Moreover, the GE Fanuc model plays a significant role in the transportation industry, where it contributes to the automation of logistics and inventory management processes. Its robust communication features enable real-time tracking and data exchange, facilitating smarter decision-making.

Comparison with Other Models

When comparing the GE Fanuc model to other offerings within the GE portfolio, such as the GE SR750 or the GE IC697MDL740, the GE Fanuc model stands out due to its superior processing capabilities and enhanced connectivity options. While the GE SR750 is exceptional in its own right, particularly for its scalability, the GE Fanuc model offers a more compact solution without compromising on power.

In relation to the GE IS200DSPXH2DBD and GE IC660BBA020, the GE Fanuc model presents a more user-friendly interface, making it accessible for operators of varying experience levels. Furthermore, the GE Fanuc model is designed with future-proofing in mind, ensuring compatibility with emerging technologies in automation.

Related Models

For those interested in exploring the full range of GE automation products, consider the following related models: GE IS200EDFFH1ABA, GE IS200JPDMG1ADC, GE DS200DDTBG2A, GE IC693APU301, GE IC200CPU005, GE IC695CPE310-ABAH, GE IS200TRPGH1BDE, GE IC694PWR331, and

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.