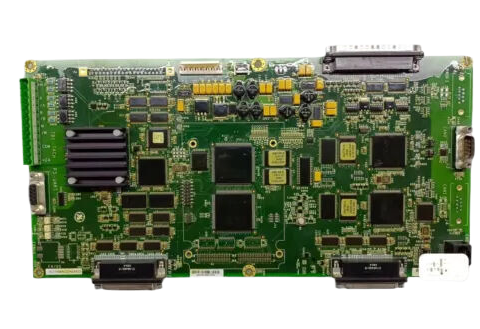

GE FANUC IC200MDL330 Discrete Output Module Advanced Industrial Control Solution

Introducing the GE FANUC, a pivotal product in GE's extensive range of automation solutions designed for maximum efficiency and reliability in industrial settings. As a leading name in the realm of automation technology, GE offers an impressive array of products to meet diverse operational needs. The GE FANUC stands out with its robust features, versatility, and seamless integration with other GE automation products, making it an ideal choice for industries looking to enhance their automation processes.

Key Technical Features:

The GE FANUC boasts an array of cutting-edge features that set it apart in the automation landscape. With a high-speed processing capability, it ensures rapid data handling and quick response times, vital for critical industrial applications. The unit is equipped with advanced communication protocols, allowing for smooth integration with existing systems and facilitating real-time data exchange. Additionally, the GE FANUC supports a wide range of input/output configurations, catering to various automation needs. Its compact design ensures ease of installation, while the rugged construction guarantees durability even in the most demanding environments.

The GE FANUC also comes with extensive diagnostic capabilities, enabling users to quickly identify and rectify issues, thereby minimizing downtime. With built-in redundancy options, it offers enhanced reliability, ensuring that your operations remain uninterrupted. Furthermore, the unit is compatible with a variety of GE’s software tools, allowing for streamlined programming and configuration.

Usage Scenarios:

The GE FANUC is perfectly suited for a multitude of applications across various industries. In manufacturing, it can be utilized for process control, machine automation, and data acquisition, enhancing operational efficiency. In the energy sector, the GE FANUC plays a crucial role in monitoring and controlling equipment, ensuring optimal performance and safety. It is also widely used in the transportation industry for traffic management systems and logistics operations.

In the field of water treatment, the GE FANUC facilitates real-time monitoring and automated control of water distribution systems, contributing to sustainable resource management. Furthermore, its capabilities extend to building automation, where it manages HVAC systems, lighting controls, and security systems, demonstrating its versatility across different sectors.

Comparison with Other Models:

When comparing the GE FANUC with other models in the GE lineup, such as the GE IS200TBCIH1BBC and GE IS220PAICH2A, the FANUC distinguishes itself with its higher processing speed and greater communication flexibility. While the IS200TBCIH1BBC is tailored for specific applications in turbine control, and the IS220PAICH2A focuses on advanced protection and control, the GE FANUC serves as a more generalized solution that can be adapted to various industrial needs.

In relation to the GE 369-HI-0-M-0-0 and GE IC697MDL250 models, the GE FANUC offers enhanced input/output capabilities and broader software integration options, making it a more versatile choice for complex automation tasks. For those looking for a compact yet powerful solution, the GE FANUC is a superior option compared to models like the GE IC660ELB912G, which is more limited in its application scope.

Reference to Related Models:

The GE FANUC is part of a comprehensive family of GE automation products, including the GE IS220PPROS1B, GE IC698CMX016, GE 531X307LTBAJG1, GE IS200TPROH1BBB, GE DS200CTBAG1ADD, GE IC670MDL640, GE IS215UCVEH2AB, GE DS200SDCCG1AGD, and GE IC697MDL350. Each of these models serves specific functions within the automation spectrum, yet the GE FANUC’s flexibility and advanced features make it a preferred choice for many applications.

In conclusion, the GE FANUC is a vital component for businesses seeking to optimize their operations through reliable and efficient automation solutions. Its robust technical features, wide-ranging applications, and superior performance in comparison to other models solidify its position as a leader in the field of industrial automation. Embrace the future of automation with GE FANUC and experience the unparalleled benefits it brings to your operations.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE FANUC boasts an array of cutting-edge features that set it apart in the automation landscape. With a high-speed processing capability, it ensures rapid data handling and quick response times, vital for critical industrial applications. The unit is equipped with advanced communication protocols, allowing for smooth integration with existing systems and facilitating real-time data exchange. Additionally, the GE FANUC supports a wide range of input/output configurations, catering to various automation needs. Its compact design ensures ease of installation, while the rugged construction guarantees durability even in the most demanding environments.

The GE FANUC also comes with extensive diagnostic capabilities, enabling users to quickly identify and rectify issues, thereby minimizing downtime. With built-in redundancy options, it offers enhanced reliability, ensuring that your operations remain uninterrupted. Furthermore, the unit is compatible with a variety of GE’s software tools, allowing for streamlined programming and configuration.

Usage Scenarios:

The GE FANUC is perfectly suited for a multitude of applications across various industries. In manufacturing, it can be utilized for process control, machine automation, and data acquisition, enhancing operational efficiency. In the energy sector, the GE FANUC plays a crucial role in monitoring and controlling equipment, ensuring optimal performance and safety. It is also widely used in the transportation industry for traffic management systems and logistics operations.

In the field of water treatment, the GE FANUC facilitates real-time monitoring and automated control of water distribution systems, contributing to sustainable resource management. Furthermore, its capabilities extend to building automation, where it manages HVAC systems, lighting controls, and security systems, demonstrating its versatility across different sectors.

Comparison with Other Models:

When comparing the GE FANUC with other models in the GE lineup, such as the GE IS200TBCIH1BBC and GE IS220PAICH2A, the FANUC distinguishes itself with its higher processing speed and greater communication flexibility. While the IS200TBCIH1BBC is tailored for specific applications in turbine control, and the IS220PAICH2A focuses on advanced protection and control, the GE FANUC serves as a more generalized solution that can be adapted to various industrial needs.

In relation to the GE 369-HI-0-M-0-0 and GE IC697MDL250 models, the GE FANUC offers enhanced input/output capabilities and broader software integration options, making it a more versatile choice for complex automation tasks. For those looking for a compact yet powerful solution, the GE FANUC is a superior option compared to models like the GE IC660ELB912G, which is more limited in its application scope.

Reference to Related Models:

The GE FANUC is part of a comprehensive family of GE automation products, including the GE IS220PPROS1B, GE IC698CMX016, GE 531X307LTBAJG1, GE IS200TPROH1BBB, GE DS200CTBAG1ADD, GE IC670MDL640, GE IS215UCVEH2AB, GE DS200SDCCG1AGD, and GE IC697MDL350. Each of these models serves specific functions within the automation spectrum, yet the GE FANUC’s flexibility and advanced features make it a preferred choice for many applications.

In conclusion, the GE FANUC is a vital component for businesses seeking to optimize their operations through reliable and efficient automation solutions. Its robust technical features, wide-ranging applications, and superior performance in comparison to other models solidify its position as a leader in the field of industrial automation. Embrace the future of automation with GE FANUC and experience the unparalleled benefits it brings to your operations.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.