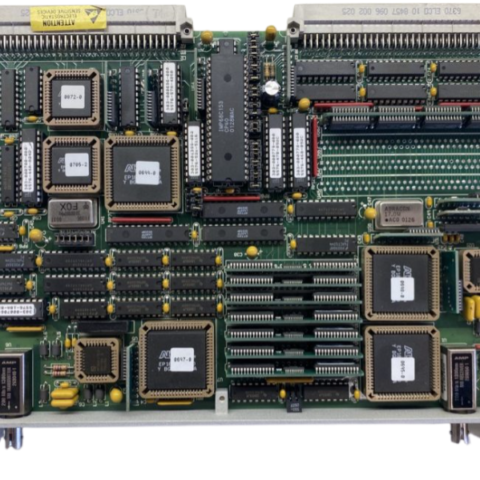

GE Fanuc F31X134EPRBEG1 Encoder Process Board

Introducing the GE Fanuc: The Ultimate Solution for Industrial Automation

The GE Fanuc is at the forefront of industrial automation technology, offering a robust solution designed to meet the demanding needs of modern manufacturing environments. Known for its reliability, efficiency, and advanced features, the GE Fanuc is the ideal choice for businesses looking to enhance their automation capabilities.

Key Technical Features

The GE Fanuc boasts a wide array of technical features that set it apart from its competitors. It is equipped with a powerful processor that ensures high-speed data processing and real-time control, making it perfect for complex manufacturing processes. The unit supports a variety of communication protocols, enabling seamless integration with existing systems and other GE automation products. Additionally, the GE Fanuc includes:

– **Modularity**: Its modular design allows for easy expansion and customization, accommodating the unique needs of different applications.

– **Durability**: Built to withstand harsh industrial environments, the GE Fanuc features rugged housing and components that ensure long-lasting performance.

– **User-Friendly Interface**: The intuitive interface simplifies programming and operation, allowing operators to quickly adapt to the system.

– **Enhanced Connectivity**: With multiple I/O options and support for various fieldbus technologies, the GE Fanuc can easily connect to sensors, actuators, and other devices within the automation ecosystem.

Usage Scenarios

The GE Fanuc is versatile and can be applied across numerous industries, including automotive, food and beverage, pharmaceuticals, and more. In automotive manufacturing, for instance, the GE Fanuc can control robotic assembly lines, ensuring precision and efficiency. In the food and beverage industry, it can monitor production lines to maintain quality control and ensure compliance with safety regulations. The GE Fanuc is equally suitable for handling complex processes in pharmaceuticals, where accuracy and reliability are paramount.

Comparison with Other Models

When compared to other models within the GE portfolio, such as the GE SR750 and GE IC697MDL740, the GE Fanuc stands out for its enhanced processing power and advanced connectivity options. While the GE SR750 is excellent for specific applications, the GE Fanuc's modularity allows for greater customization and scalability. In contrast to the GE IC697MDL740, which is more focused on discrete control, the GE Fanuc provides a comprehensive solution that integrates seamlessly with both discrete and process automation.

Related Models

For those considering the GE Fanuc, other related models within the GE automation products line are worth exploring. The GE IS200DSPXH2DBD offers specialized functionality for process control, while the GE IC660BBA020 features advanced communication capabilities. The GE DS200DDTBG2A is another model that excels in monitoring and control applications. Additionally, the GE IC693APU301 and GE IS200VTURH1BAC provide unique features for specific automation challenges.

Other notable mentions include the GE IC200CPU005, which is designed for compact applications, the GE IC695CPE310-ABAH for enhanced processing power, and

The above parameters are for reference only. Please contact our technical team for precise selection.

The GE Fanuc is at the forefront of industrial automation technology, offering a robust solution designed to meet the demanding needs of modern manufacturing environments. Known for its reliability, efficiency, and advanced features, the GE Fanuc is the ideal choice for businesses looking to enhance their automation capabilities.

Key Technical Features

The GE Fanuc boasts a wide array of technical features that set it apart from its competitors. It is equipped with a powerful processor that ensures high-speed data processing and real-time control, making it perfect for complex manufacturing processes. The unit supports a variety of communication protocols, enabling seamless integration with existing systems and other GE automation products. Additionally, the GE Fanuc includes:

– **Modularity**: Its modular design allows for easy expansion and customization, accommodating the unique needs of different applications.

– **Durability**: Built to withstand harsh industrial environments, the GE Fanuc features rugged housing and components that ensure long-lasting performance.

– **User-Friendly Interface**: The intuitive interface simplifies programming and operation, allowing operators to quickly adapt to the system.

– **Enhanced Connectivity**: With multiple I/O options and support for various fieldbus technologies, the GE Fanuc can easily connect to sensors, actuators, and other devices within the automation ecosystem.

Usage Scenarios

The GE Fanuc is versatile and can be applied across numerous industries, including automotive, food and beverage, pharmaceuticals, and more. In automotive manufacturing, for instance, the GE Fanuc can control robotic assembly lines, ensuring precision and efficiency. In the food and beverage industry, it can monitor production lines to maintain quality control and ensure compliance with safety regulations. The GE Fanuc is equally suitable for handling complex processes in pharmaceuticals, where accuracy and reliability are paramount.

Comparison with Other Models

When compared to other models within the GE portfolio, such as the GE SR750 and GE IC697MDL740, the GE Fanuc stands out for its enhanced processing power and advanced connectivity options. While the GE SR750 is excellent for specific applications, the GE Fanuc's modularity allows for greater customization and scalability. In contrast to the GE IC697MDL740, which is more focused on discrete control, the GE Fanuc provides a comprehensive solution that integrates seamlessly with both discrete and process automation.

Related Models

For those considering the GE Fanuc, other related models within the GE automation products line are worth exploring. The GE IS200DSPXH2DBD offers specialized functionality for process control, while the GE IC660BBA020 features advanced communication capabilities. The GE DS200DDTBG2A is another model that excels in monitoring and control applications. Additionally, the GE IC693APU301 and GE IS200VTURH1BAC provide unique features for specific automation challenges.

Other notable mentions include the GE IC200CPU005, which is designed for compact applications, the GE IC695CPE310-ABAH for enhanced processing power, and

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.