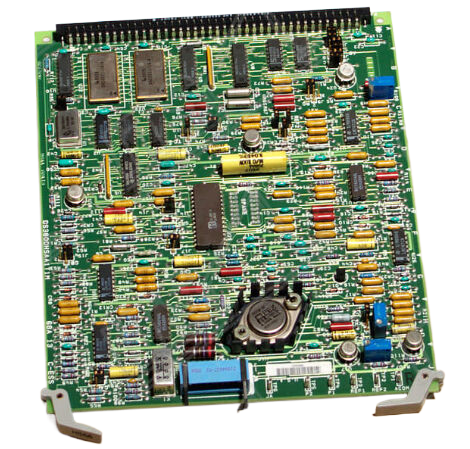

GE Fanuc DS200TBCAG1A Analog I/O Terminal Board for Industrial Automation

Introducing the GE Fanuc: the pinnacle of industrial automation solutions engineered for reliability and performance. The GE Fanuc series stands out in the realm of GE automation products, offering a comprehensive suite of features designed to optimize your operations and enhance productivity.

Key Technical Features

At the heart of the GE Fanuc model is its robust architecture, featuring advanced processing capabilities that ensure swift and efficient data handling. The system boasts an extensive range of I/O options, allowing for seamless integration with various sensors, actuators, and other devices. This versatility is complemented by high-speed communication protocols, enabling real-time data exchange and minimizing latency.

One of the standout features of the GE Fanuc model is its scalability. Whether you are managing a small facility or a large industrial complex, the system can be tailored to meet your specific needs. Additionally, the GE Fanuc offers exceptional diagnostic capabilities, providing users with insights into system performance and potential areas for maintenance, thereby reducing downtime.

The GE Fanuc model is designed with user-friendliness in mind. Its intuitive interface simplifies programming and operation, making it accessible for both experienced technicians and newcomers to automation technology. Furthermore, the system is compatible with a wide range of software applications, enhancing its functionality and integrating seamlessly into existing workflows.

Usage Scenarios

The GE Fanuc excels in a variety of industrial applications, making it an ideal choice for manufacturing, process control, and assembly line operations. In manufacturing, the GE Fanuc can streamline production processes, optimize machine performance, and reduce waste, ultimately leading to increased profitability.

In process control applications, the GE Fanuc ensures precise monitoring and regulation of critical parameters, such as temperature, pressure, and flow rates. This capability is essential in industries such as oil and gas, pharmaceuticals, and food processing, where compliance with strict safety and quality standards is paramount.

Additionally, the GE Fanuc model is perfect for assembly line automation, where its capability to synchronize multiple machines and processes can significantly enhance efficiency. By employing the GE Fanuc, businesses can achieve higher output rates while maintaining the highest standards of quality.

Comparison with Other Models

When compared to other models within the GE product line, such as the GE SR750 or GE IS200DSPXH2DBD, the GE Fanuc distinguishes itself through its superior processing speed and enhanced I/O flexibility. While the GE SR750 is designed for high-performance applications, the GE Fanuc offers a more adaptable solution, making it suitable for a broader range of industries.

In contrast to the GE IC697MDL740, which is primarily focused on discrete I/O applications, the GE Fanuc provides a more integrated approach, catering to both discrete and analog inputs and outputs. This adaptability allows users to expand their systems without the need for extensive overhauls.

For applications requiring extensive networking capabilities, the GE Fanuc outshines models like the GE IC200CPU005, offering advanced communication protocols that facilitate seamless integration into complex networks.

Reference to Related Models

The GE Fan

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

At the heart of the GE Fanuc model is its robust architecture, featuring advanced processing capabilities that ensure swift and efficient data handling. The system boasts an extensive range of I/O options, allowing for seamless integration with various sensors, actuators, and other devices. This versatility is complemented by high-speed communication protocols, enabling real-time data exchange and minimizing latency.

One of the standout features of the GE Fanuc model is its scalability. Whether you are managing a small facility or a large industrial complex, the system can be tailored to meet your specific needs. Additionally, the GE Fanuc offers exceptional diagnostic capabilities, providing users with insights into system performance and potential areas for maintenance, thereby reducing downtime.

The GE Fanuc model is designed with user-friendliness in mind. Its intuitive interface simplifies programming and operation, making it accessible for both experienced technicians and newcomers to automation technology. Furthermore, the system is compatible with a wide range of software applications, enhancing its functionality and integrating seamlessly into existing workflows.

Usage Scenarios

The GE Fanuc excels in a variety of industrial applications, making it an ideal choice for manufacturing, process control, and assembly line operations. In manufacturing, the GE Fanuc can streamline production processes, optimize machine performance, and reduce waste, ultimately leading to increased profitability.

In process control applications, the GE Fanuc ensures precise monitoring and regulation of critical parameters, such as temperature, pressure, and flow rates. This capability is essential in industries such as oil and gas, pharmaceuticals, and food processing, where compliance with strict safety and quality standards is paramount.

Additionally, the GE Fanuc model is perfect for assembly line automation, where its capability to synchronize multiple machines and processes can significantly enhance efficiency. By employing the GE Fanuc, businesses can achieve higher output rates while maintaining the highest standards of quality.

Comparison with Other Models

When compared to other models within the GE product line, such as the GE SR750 or GE IS200DSPXH2DBD, the GE Fanuc distinguishes itself through its superior processing speed and enhanced I/O flexibility. While the GE SR750 is designed for high-performance applications, the GE Fanuc offers a more adaptable solution, making it suitable for a broader range of industries.

In contrast to the GE IC697MDL740, which is primarily focused on discrete I/O applications, the GE Fanuc provides a more integrated approach, catering to both discrete and analog inputs and outputs. This adaptability allows users to expand their systems without the need for extensive overhauls.

For applications requiring extensive networking capabilities, the GE Fanuc outshines models like the GE IC200CPU005, offering advanced communication protocols that facilitate seamless integration into complex networks.

Reference to Related Models

The GE Fan

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.