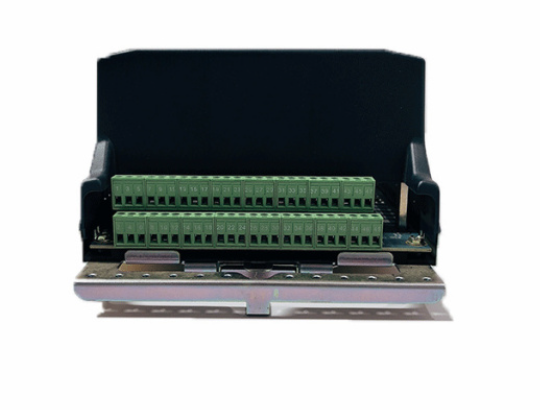

GE Fanuc DS200LDCCH1 Circuit Board Advanced Control Module for Industrial Automation

Introducing the GE Fanuc, a robust and versatile solution in the realm of industrial automation. This model stands out with its advanced technical features designed to enhance operational efficiency and reliability in various applications. As part of GE's renowned line of automation products, the GE Fanuc delivers superior performance and integrates seamlessly into existing systems, making it a preferred choice among professionals in diverse industries.

Key Technical Features:

The GE Fanuc is engineered with a powerful processing unit capable of handling complex tasks with remarkable speed and accuracy. It features a user-friendly interface that simplifies programming and monitoring, ensuring that operators can easily manage processes. The device supports a wide range of I/O modules, allowing for extensive customization to meet specific application needs. Its robust communication capabilities enable integration with various protocols, enhancing connectivity with other GE automation products and third-party devices. Additionally, the GE Fanuc is built to withstand harsh environments, featuring a durable casing and advanced thermal management systems, ensuring longevity and reliability in demanding situations.

Usage Scenarios:

The GE Fanuc is ideal for a multitude of applications across various sectors. In manufacturing, it can be utilized for process control, machine automation, and real-time data acquisition, enabling businesses to streamline operations and maximize productivity. In the oil and gas industry, it is employed for monitoring and controlling equipment, ensuring safety and efficiency in operations. The GE Fanuc also finds its place in the energy sector, where it aids in managing power distribution systems and optimizing performance. Its versatility makes it suitable for any industry that requires precise control and monitoring of automated systems.

Comparison with Other Models:

When compared to other models in the GE product line, such as the GE SR750 or the GE IS200DSPXH2DBD, the GE Fanuc offers a unique combination of power and flexibility. While the SR750 excels in high-speed applications, the GE Fanuc's adaptability makes it suitable for a broader range of scenarios. In contrast to the GE IC697MDL740, which focuses on I/O processing, the GE Fanuc provides a more comprehensive solution with its advanced processing capabilities and communication options. The GE IS200DSFCG1AEB stands out for its specific use in turbine control, whereas the GE Fanuc offers a more general approach to automation, making it a versatile choice for various industries.

Related Models:

For those looking to explore further within the GE automation product ecosystem, consider the following models: GE IC660BBA020, known for its rugged performance; GE DS200DDTBG2A, which specializes in digital input/output; GE IS200DSPXH2DBD, a reliable solution for digital signal processing; GE ALG, which integrates advanced algorithms for enhanced processing; GE IC200CPU005, a compact CPU option; GE IC3600A0AHIC, designed for legacy systems; GE IC695CPE310-ABAH, offering high-speed performance; GE IS200EDFFH1ABA, which excels in distributed control systems; GE IC695LRE001

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE Fanuc is engineered with a powerful processing unit capable of handling complex tasks with remarkable speed and accuracy. It features a user-friendly interface that simplifies programming and monitoring, ensuring that operators can easily manage processes. The device supports a wide range of I/O modules, allowing for extensive customization to meet specific application needs. Its robust communication capabilities enable integration with various protocols, enhancing connectivity with other GE automation products and third-party devices. Additionally, the GE Fanuc is built to withstand harsh environments, featuring a durable casing and advanced thermal management systems, ensuring longevity and reliability in demanding situations.

Usage Scenarios:

The GE Fanuc is ideal for a multitude of applications across various sectors. In manufacturing, it can be utilized for process control, machine automation, and real-time data acquisition, enabling businesses to streamline operations and maximize productivity. In the oil and gas industry, it is employed for monitoring and controlling equipment, ensuring safety and efficiency in operations. The GE Fanuc also finds its place in the energy sector, where it aids in managing power distribution systems and optimizing performance. Its versatility makes it suitable for any industry that requires precise control and monitoring of automated systems.

Comparison with Other Models:

When compared to other models in the GE product line, such as the GE SR750 or the GE IS200DSPXH2DBD, the GE Fanuc offers a unique combination of power and flexibility. While the SR750 excels in high-speed applications, the GE Fanuc's adaptability makes it suitable for a broader range of scenarios. In contrast to the GE IC697MDL740, which focuses on I/O processing, the GE Fanuc provides a more comprehensive solution with its advanced processing capabilities and communication options. The GE IS200DSFCG1AEB stands out for its specific use in turbine control, whereas the GE Fanuc offers a more general approach to automation, making it a versatile choice for various industries.

Related Models:

For those looking to explore further within the GE automation product ecosystem, consider the following models: GE IC660BBA020, known for its rugged performance; GE DS200DDTBG2A, which specializes in digital input/output; GE IS200DSPXH2DBD, a reliable solution for digital signal processing; GE ALG, which integrates advanced algorithms for enhanced processing; GE IC200CPU005, a compact CPU option; GE IC3600A0AHIC, designed for legacy systems; GE IC695CPE310-ABAH, offering high-speed performance; GE IS200EDFFH1ABA, which excels in distributed control systems; GE IC695LRE001

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.