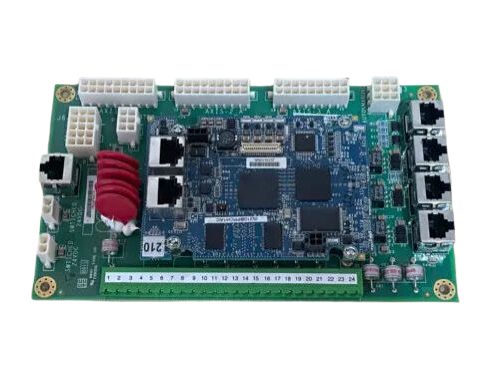

GE Electric DS200TCQCG1B RST Overflow Board for Turbine Control Systems

Introducing the GE Electric Model: the pinnacle of efficiency and innovation in the realm of automation technologies. Designed specifically for industrial applications, this state-of-the-art electric model by GE embodies reliability, power, and precision. With its advanced features and robust construction, the GE Electric model stands out as a key player in the landscape of GE automation products.

Key Technical Features

The GE Electric model is equipped with a range of cutting-edge technical features that enhance its functionality and versatility. Key among these is its high-performance processor, which delivers rapid data processing and control capabilities. This processor ensures that the model can handle complex tasks with ease, making it ideal for demanding industrial environments. Additionally, the model boasts extensive I/O options, allowing for seamless integration with various sensors and devices, which is essential for real-time monitoring and control.

The robust design of the GE Electric model includes advanced thermal management technology, ensuring optimal performance even under strenuous conditions. With an operating temperature range that accommodates extreme environments, this model is as durable as it is efficient. Furthermore, it supports multiple communication protocols, providing flexibility in connectivity and ensuring compatibility with an extensive array of GE automation products and systems.

Usage Scenarios

The GE Electric model is perfect for a wide variety of industrial applications. Whether you are operating in manufacturing, energy production, or transportation sectors, this model can cater to your automation needs. For instance, in a manufacturing plant, the GE Electric model can be used to control machinery, monitor production lines, and optimize workflow processes, leading to increased productivity and reduced operational costs.

In the energy sector, this model excels in managing power distribution systems, ensuring that energy flows efficiently and reliably. Its ability to integrate with renewable energy sources makes it an excellent choice for organizations looking to adopt sustainable practices. Additionally, in transportation, the GE Electric model can enhance traffic management systems, ensuring smooth operations and improved safety.

Comparison with Other Models

When comparing the GE Electric model to other models within the GE lineup, such as the GE IS220PPROS1B and GE EVMECNTM13, the differences become apparent. While the IS220PPROS1B is tailored for process control with specific functionality, the GE Electric model offers a more comprehensive solution suitable for broader applications. The EVMECNTM13, on the other hand, focuses on motor control, which, while important, lacks the versatility that the GE Electric model provides.

Furthermore, the GE Electric model showcases improved processing speeds compared to models like the GE IC697MDL250 and GE IS200DSPXH1DBC. This enhanced speed allows for quicker response times and a more efficient automation process overall.

Related Models

For those interested in exploring more of GE's offerings, consider these related models: GE IS200TBCIH1BBC, GE CT7P70500470CW24, GE IS220PAICH2A, GE IS215UCVEH2AB, GE IS230SNIDH1A, GE IC670MDL740J, GE DS200CTBAG1ADD, GE IS200TPROH1BCB, GE IC698ACC701, and GE 531X307LTBAJG1. Each model brings unique capabilities to the table, catering to various industrial needs, but none rival the overall performance and versatility of the GE Electric model.

Conclusion

In conclusion, the GE Electric model represents a significant advancement in the field of automation technology, combining powerful features with unparalleled versatility. Whether you are looking to enhance your manufacturing processes, improve energy management, or optimize transportation systems, the GE Electric model is your go-to solution. Its compatibility with other GE automation products ensures that you can create a cohesive and efficient automation ecosystem tailored to your specific needs. Choose the GE Electric model for a reliable, efficient, and innovative approach to industrial automation.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE Electric model is equipped with a range of cutting-edge technical features that enhance its functionality and versatility. Key among these is its high-performance processor, which delivers rapid data processing and control capabilities. This processor ensures that the model can handle complex tasks with ease, making it ideal for demanding industrial environments. Additionally, the model boasts extensive I/O options, allowing for seamless integration with various sensors and devices, which is essential for real-time monitoring and control.

The robust design of the GE Electric model includes advanced thermal management technology, ensuring optimal performance even under strenuous conditions. With an operating temperature range that accommodates extreme environments, this model is as durable as it is efficient. Furthermore, it supports multiple communication protocols, providing flexibility in connectivity and ensuring compatibility with an extensive array of GE automation products and systems.

Usage Scenarios

The GE Electric model is perfect for a wide variety of industrial applications. Whether you are operating in manufacturing, energy production, or transportation sectors, this model can cater to your automation needs. For instance, in a manufacturing plant, the GE Electric model can be used to control machinery, monitor production lines, and optimize workflow processes, leading to increased productivity and reduced operational costs.

In the energy sector, this model excels in managing power distribution systems, ensuring that energy flows efficiently and reliably. Its ability to integrate with renewable energy sources makes it an excellent choice for organizations looking to adopt sustainable practices. Additionally, in transportation, the GE Electric model can enhance traffic management systems, ensuring smooth operations and improved safety.

Comparison with Other Models

When comparing the GE Electric model to other models within the GE lineup, such as the GE IS220PPROS1B and GE EVMECNTM13, the differences become apparent. While the IS220PPROS1B is tailored for process control with specific functionality, the GE Electric model offers a more comprehensive solution suitable for broader applications. The EVMECNTM13, on the other hand, focuses on motor control, which, while important, lacks the versatility that the GE Electric model provides.

Furthermore, the GE Electric model showcases improved processing speeds compared to models like the GE IC697MDL250 and GE IS200DSPXH1DBC. This enhanced speed allows for quicker response times and a more efficient automation process overall.

Related Models

For those interested in exploring more of GE's offerings, consider these related models: GE IS200TBCIH1BBC, GE CT7P70500470CW24, GE IS220PAICH2A, GE IS215UCVEH2AB, GE IS230SNIDH1A, GE IC670MDL740J, GE DS200CTBAG1ADD, GE IS200TPROH1BCB, GE IC698ACC701, and GE 531X307LTBAJG1. Each model brings unique capabilities to the table, catering to various industrial needs, but none rival the overall performance and versatility of the GE Electric model.

Conclusion

In conclusion, the GE Electric model represents a significant advancement in the field of automation technology, combining powerful features with unparalleled versatility. Whether you are looking to enhance your manufacturing processes, improve energy management, or optimize transportation systems, the GE Electric model is your go-to solution. Its compatibility with other GE automation products ensures that you can create a cohesive and efficient automation ecosystem tailored to your specific needs. Choose the GE Electric model for a reliable, efficient, and innovative approach to industrial automation.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.