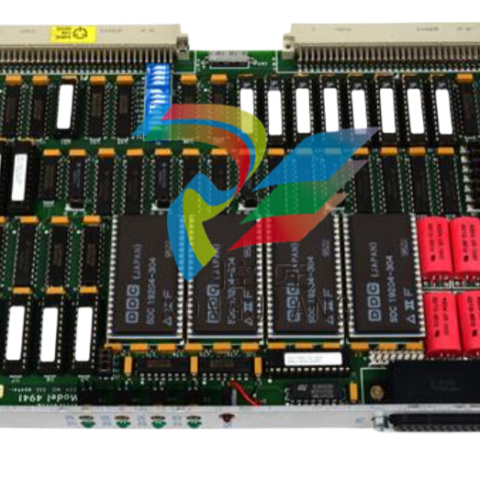

GE DA512 Advanced Thickness Measurement Probe for Industrial Applications

Introducing the GE DA512, a cutting-edge addition to the GE family of automation products designed to elevate efficiency and reliability in various industrial applications. This model stands out with its robust technical features, making it a versatile choice for engineers and operators alike.

Key Technical Features

The GE DA512 boasts a high-performance processor that ensures rapid data processing and seamless communication across systems. With a compact design, it integrates easily into existing setups without compromising space. The unit supports a wide range of input and output configurations, providing flexibility for various automation tasks. Its exceptional data handling capabilities allow for real-time monitoring and control, making it ideal for both simple and complex operations. The DA512 is equipped with advanced diagnostics features, enabling users to quickly identify and troubleshoot issues, thereby minimizing downtime and enhancing productivity.

The GE DA512 also incorporates enhanced connectivity options, allowing it to interface with other GE automation products and third-party devices effortlessly. Built-in support for multiple communication protocols ensures that the DA512 can be deployed in diverse environments, accommodating different operational requirements.

Usage Scenarios

The GE DA512 is perfect for a multitude of usage scenarios, ranging from manufacturing and process control to energy management and transportation systems. In a manufacturing plant, for instance, the DA512 can be utilized to monitor equipment performance, automate production lines, and optimize resource allocation. In process control applications, it helps manage complex workflows, ensuring smooth operations and adherence to safety standards.

In energy management systems, the GE DA512 can facilitate real-time data analysis, allowing operators to make informed decisions that optimize energy consumption. Similarly, in transportation, it can be employed to manage traffic systems, ensuring efficient flow and reducing congestion. Its versatility makes the DA512 an invaluable asset in any industrial setting.

Comparison with Other Models

When comparing the GE DA512 to other models within the GE automation product line, such as the GE IS200TPROH1BCB and GE IS220PPROS1B, the DA512 offers several advantages. While the IS200TPROH1BCB excels in process control, the DA512's broader range of connectivity options and enhanced processing capabilities make it a more adaptable solution for various applications.

Moreover, when placed alongside the GE IC697MDL653, known for its I/O capabilities, the DA512 emerges as a more integrated solution due to its advanced data handling features and ease of integration with existing systems. The DA512 stands out as a robust choice for industries that require both flexibility and reliability in their automation processes.

Reference to Related Models

In addition to the GE DA512, professionals can explore other related models that complement its functionality. The GE IS200DSPXH1DBC, GE IS230SNIDH1A, and GE IS200TPROH1BBB offer varying degrees of process control capabilities. For those focused on I/O modules, the GE IC697MDL250 and GE IC670MDL640 present excellent alternatives.

The GE IC693CPU374 and GE IC698CMX016 are also worth considering for their computing power and communication capabilities. Additionally, models like the GE DS200CTBAG1ADD and GE DS200SDCCG1AGD provide advanced diagnostics and monitoring solutions that can enhance the overall performance of automation systems.

In conclusion, the GE DA512 is designed for modern industrial applications where efficiency, flexibility, and reliability are paramount. With its state-of-the-art technical features, adaptability to various scenarios, and competitive edge over other models, the GE DA512 is a smart investment for any organization looking to streamline their automation processes. Explore the full potential of the GE DA512 and experience the difference that advanced automation products can make in your operations.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE DA512 boasts a high-performance processor that ensures rapid data processing and seamless communication across systems. With a compact design, it integrates easily into existing setups without compromising space. The unit supports a wide range of input and output configurations, providing flexibility for various automation tasks. Its exceptional data handling capabilities allow for real-time monitoring and control, making it ideal for both simple and complex operations. The DA512 is equipped with advanced diagnostics features, enabling users to quickly identify and troubleshoot issues, thereby minimizing downtime and enhancing productivity.

The GE DA512 also incorporates enhanced connectivity options, allowing it to interface with other GE automation products and third-party devices effortlessly. Built-in support for multiple communication protocols ensures that the DA512 can be deployed in diverse environments, accommodating different operational requirements.

Usage Scenarios

The GE DA512 is perfect for a multitude of usage scenarios, ranging from manufacturing and process control to energy management and transportation systems. In a manufacturing plant, for instance, the DA512 can be utilized to monitor equipment performance, automate production lines, and optimize resource allocation. In process control applications, it helps manage complex workflows, ensuring smooth operations and adherence to safety standards.

In energy management systems, the GE DA512 can facilitate real-time data analysis, allowing operators to make informed decisions that optimize energy consumption. Similarly, in transportation, it can be employed to manage traffic systems, ensuring efficient flow and reducing congestion. Its versatility makes the DA512 an invaluable asset in any industrial setting.

Comparison with Other Models

When comparing the GE DA512 to other models within the GE automation product line, such as the GE IS200TPROH1BCB and GE IS220PPROS1B, the DA512 offers several advantages. While the IS200TPROH1BCB excels in process control, the DA512's broader range of connectivity options and enhanced processing capabilities make it a more adaptable solution for various applications.

Moreover, when placed alongside the GE IC697MDL653, known for its I/O capabilities, the DA512 emerges as a more integrated solution due to its advanced data handling features and ease of integration with existing systems. The DA512 stands out as a robust choice for industries that require both flexibility and reliability in their automation processes.

Reference to Related Models

In addition to the GE DA512, professionals can explore other related models that complement its functionality. The GE IS200DSPXH1DBC, GE IS230SNIDH1A, and GE IS200TPROH1BBB offer varying degrees of process control capabilities. For those focused on I/O modules, the GE IC697MDL250 and GE IC670MDL640 present excellent alternatives.

The GE IC693CPU374 and GE IC698CMX016 are also worth considering for their computing power and communication capabilities. Additionally, models like the GE DS200CTBAG1ADD and GE DS200SDCCG1AGD provide advanced diagnostics and monitoring solutions that can enhance the overall performance of automation systems.

In conclusion, the GE DA512 is designed for modern industrial applications where efficiency, flexibility, and reliability are paramount. With its state-of-the-art technical features, adaptability to various scenarios, and competitive edge over other models, the GE DA512 is a smart investment for any organization looking to streamline their automation processes. Explore the full potential of the GE DA512 and experience the difference that advanced automation products can make in your operations.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.