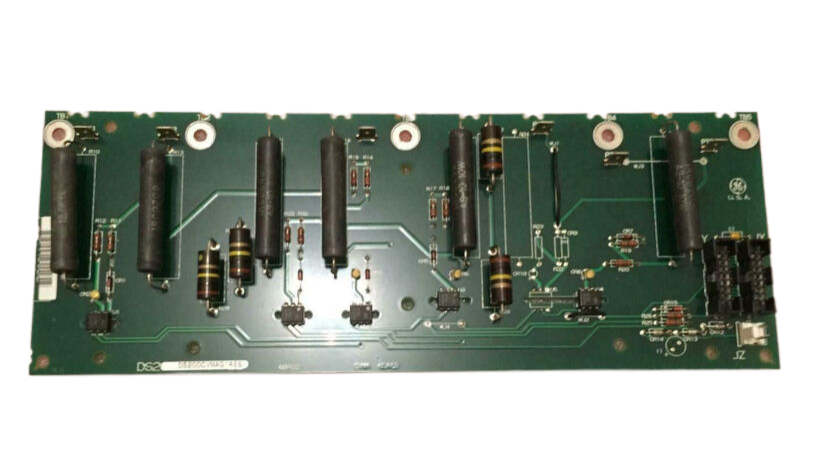

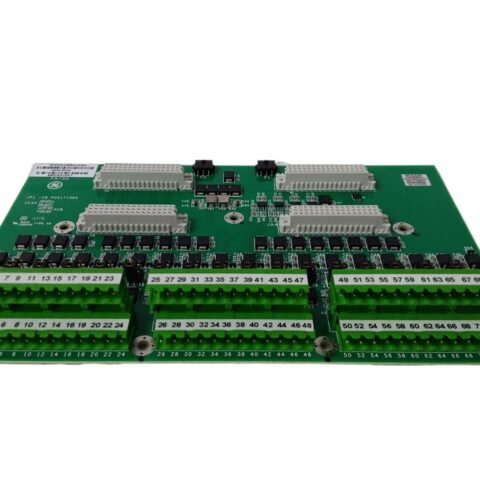

GE Control Systems VL-202A08L-1021 Programmable Logic Controller

Introducing the GE Control: a pinnacle of innovation in industrial automation designed to enhance operational efficiency and reliability. With a robust suite of features, the GE Control stands at the forefront of GE automation products, catering to a diverse range of applications in various industries, from manufacturing to energy and transportation.

Key Technical Features

The GE Control boasts an array of advanced technical features that set it apart in the realm of industrial automation. Its modular architecture allows for seamless integration with existing systems, making it highly adaptable to various operational requirements. Equipped with high-speed processing capabilities, the GE Control ensures rapid data handling and real-time decision-making, which is crucial for maintaining productivity in fast-paced environments.

Additionally, the GE Control supports multiple communication protocols, including Ethernet/IP, Modbus TCP, and CANopen, allowing for versatile connectivity with other devices and systems. This feature is particularly beneficial for industries seeking to implement IoT solutions, as it enables streamlined data exchange and enhanced monitoring capabilities.

The GE Control also prioritizes safety with built-in redundancy features and compliance with international safety standards. This attention to safety not only protects personnel and equipment but also ensures uninterrupted operations, reducing downtime significantly.

Usage Scenarios

The versatility of the GE Control makes it suitable for a wide range of applications. In manufacturing, it can be utilized for process control, machine automation, and system monitoring, facilitating efficient production workflows. In the energy sector, the GE Control excels in power management and distribution, ensuring optimal performance of electrical grids and renewable energy systems.

Moreover, in transportation, the GE Control can be employed in traffic management systems and railway signaling, enhancing safety and operational efficiency. Its adaptability is ideal for environments that demand precision and reliability, making it a preferred choice for engineers and operators alike.

Comparison with Other Models

When comparing the GE Control with other models within the GE automation products lineup, such as the GE SR750 and GE IS200DSFCG1AEB, the GE Control stands out for its superior processing speed and enhanced connectivity options. While the SR750 offers solid performance for basic automation tasks, the GE Control provides the scalability needed for more complex systems and larger operations.

In contrast to the GE IC697MDL740, known for its reliability in discrete control applications, the GE Control’s advanced communication capabilities make it a more versatile choice for integrated systems where data exchange and real-time processing are paramount. The GE IS200DSPXH2DBD, while effective in specific control applications, lacks the extensive modularity and scalability that the GE Control offers, making it less adaptable for evolving operational needs.

Reference to Related Models

For those considering the GE Control, it is beneficial to look at other related models within the GE portfolio. These include the GE IC660BBA020, GE DS200DDTBG2A, and GE IS220PPDAH1A, each serving unique automation functions. The GE FANUC series, with models like the GE IC200CPU005 and GE IC695CPE310-ABAH, showcases a

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE Control boasts an array of advanced technical features that set it apart in the realm of industrial automation. Its modular architecture allows for seamless integration with existing systems, making it highly adaptable to various operational requirements. Equipped with high-speed processing capabilities, the GE Control ensures rapid data handling and real-time decision-making, which is crucial for maintaining productivity in fast-paced environments.

Additionally, the GE Control supports multiple communication protocols, including Ethernet/IP, Modbus TCP, and CANopen, allowing for versatile connectivity with other devices and systems. This feature is particularly beneficial for industries seeking to implement IoT solutions, as it enables streamlined data exchange and enhanced monitoring capabilities.

The GE Control also prioritizes safety with built-in redundancy features and compliance with international safety standards. This attention to safety not only protects personnel and equipment but also ensures uninterrupted operations, reducing downtime significantly.

Usage Scenarios

The versatility of the GE Control makes it suitable for a wide range of applications. In manufacturing, it can be utilized for process control, machine automation, and system monitoring, facilitating efficient production workflows. In the energy sector, the GE Control excels in power management and distribution, ensuring optimal performance of electrical grids and renewable energy systems.

Moreover, in transportation, the GE Control can be employed in traffic management systems and railway signaling, enhancing safety and operational efficiency. Its adaptability is ideal for environments that demand precision and reliability, making it a preferred choice for engineers and operators alike.

Comparison with Other Models

When comparing the GE Control with other models within the GE automation products lineup, such as the GE SR750 and GE IS200DSFCG1AEB, the GE Control stands out for its superior processing speed and enhanced connectivity options. While the SR750 offers solid performance for basic automation tasks, the GE Control provides the scalability needed for more complex systems and larger operations.

In contrast to the GE IC697MDL740, known for its reliability in discrete control applications, the GE Control’s advanced communication capabilities make it a more versatile choice for integrated systems where data exchange and real-time processing are paramount. The GE IS200DSPXH2DBD, while effective in specific control applications, lacks the extensive modularity and scalability that the GE Control offers, making it less adaptable for evolving operational needs.

Reference to Related Models

For those considering the GE Control, it is beneficial to look at other related models within the GE portfolio. These include the GE IC660BBA020, GE DS200DDTBG2A, and GE IS220PPDAH1A, each serving unique automation functions. The GE FANUC series, with models like the GE IC200CPU005 and GE IC695CPE310-ABAH, showcases a

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.