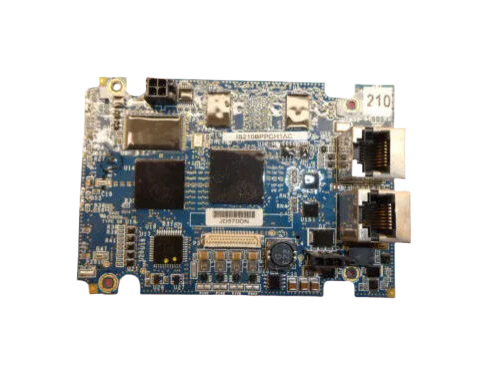

GE 369B1844G5004 Input Module Precision Control Solutions for Industrial Automation

Introducing the GE 369B1844G5004, a cutting-edge component designed to elevate your automation applications to new heights. As part of GE's esteemed line of industrial automation products, this model stands out with its innovative features and robust performance, making it an essential asset for your operational needs.

Key Technical Features:

The GE 369B1844G5004 is engineered to deliver exceptional reliability and efficiency, boasting advanced specifications that enhance its functionality. This model features high-speed processing capabilities, enabling rapid data handling and streamlined operations. It supports multiple communication protocols, ensuring seamless integration with various systems and devices, which is critical in today’s interconnected manufacturing environments. Designed with a user-friendly interface, the GE 369B1844G5004 facilitates easy programming and configuration, minimizing downtime and optimizing productivity.

Additionally, the unit is built for durability, withstanding harsh industrial conditions. Its robust construction ensures longevity, making it a cost-effective solution in the long run. With built-in diagnostic capabilities, the GE 369B1844G5004 allows for easy troubleshooting and maintenance, further reducing operational interruptions.

Usage Scenarios:

The GE 369B1844G5004 is versatile and ideal for a wide range of applications across various industries. Whether you are managing complex manufacturing processes, automating assembly lines, or optimizing supply chain logistics, this model provides the reliability and precision you need. It excels in environments requiring real-time data processing and control, such as in automotive manufacturing, food and beverage production, and pharmaceuticals.

For instance, in an automotive assembly line, the GE 369B1844G5004 can be integrated to manage robotic systems, ensuring synchronized operations and minimizing errors. In food and beverage, it can monitor and control production lines, ensuring compliance with safety standards while maximizing throughput. Its adaptability makes it a go-to solution for industrial automation.

Comparison with Other Models:

When comparing the GE 369B1844G5004 with other models in the GE product line, such as the GE SR750 and GE IC697MDL740, it is evident that this model offers superior processing speed and flexibility. While the GE SR750 is well-regarded for its reliability, the 369B1844G5004 takes it a step further with enhanced communication options and programming ease.

Additionally, the GE IS200DSPXH2DBD and GE IC660BBA020 are excellent models but may lack the comprehensive diagnostic features that the 369B1844G5004 provides. The advanced troubleshooting capabilities of the GE 369B1844G5004 give it a competitive edge, making it a preferred choice for those who require minimal downtime.

Related Models:

For those exploring additional options within the GE automation products range, consider the following related models: GE IS200EDFFH1ABA, GE IC695CPE310-ABAH, GE DS200DDTBG2A, GE IC200CPU005, GE IS200VTURH1BAC, GE FAN

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE 369B1844G5004 is engineered to deliver exceptional reliability and efficiency, boasting advanced specifications that enhance its functionality. This model features high-speed processing capabilities, enabling rapid data handling and streamlined operations. It supports multiple communication protocols, ensuring seamless integration with various systems and devices, which is critical in today’s interconnected manufacturing environments. Designed with a user-friendly interface, the GE 369B1844G5004 facilitates easy programming and configuration, minimizing downtime and optimizing productivity.

Additionally, the unit is built for durability, withstanding harsh industrial conditions. Its robust construction ensures longevity, making it a cost-effective solution in the long run. With built-in diagnostic capabilities, the GE 369B1844G5004 allows for easy troubleshooting and maintenance, further reducing operational interruptions.

Usage Scenarios:

The GE 369B1844G5004 is versatile and ideal for a wide range of applications across various industries. Whether you are managing complex manufacturing processes, automating assembly lines, or optimizing supply chain logistics, this model provides the reliability and precision you need. It excels in environments requiring real-time data processing and control, such as in automotive manufacturing, food and beverage production, and pharmaceuticals.

For instance, in an automotive assembly line, the GE 369B1844G5004 can be integrated to manage robotic systems, ensuring synchronized operations and minimizing errors. In food and beverage, it can monitor and control production lines, ensuring compliance with safety standards while maximizing throughput. Its adaptability makes it a go-to solution for industrial automation.

Comparison with Other Models:

When comparing the GE 369B1844G5004 with other models in the GE product line, such as the GE SR750 and GE IC697MDL740, it is evident that this model offers superior processing speed and flexibility. While the GE SR750 is well-regarded for its reliability, the 369B1844G5004 takes it a step further with enhanced communication options and programming ease.

Additionally, the GE IS200DSPXH2DBD and GE IC660BBA020 are excellent models but may lack the comprehensive diagnostic features that the 369B1844G5004 provides. The advanced troubleshooting capabilities of the GE 369B1844G5004 give it a competitive edge, making it a preferred choice for those who require minimal downtime.

Related Models:

For those exploring additional options within the GE automation products range, consider the following related models: GE IS200EDFFH1ABA, GE IC695CPE310-ABAH, GE DS200DDTBG2A, GE IC200CPU005, GE IS200VTURH1BAC, GE FAN

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.