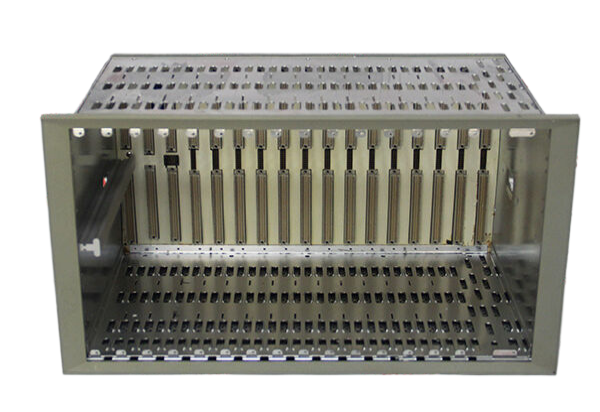

BENTLY Nevada 330102-05-20-10-02-05 Proximity Probes for Industrial Automation

Introducing the BENTLY Nevada: The Pinnacle of Industrial Monitoring and Control

BENTLY Nevada has long been recognized as a leader in the realm of industrial automation products, and the BENTLY Nevada model is no exception. Designed to enhance operational efficiency and reliability, this advanced monitoring system offers a comprehensive suite of features tailored for demanding industrial environments.

Key Technical Features

The BENTLY Nevada is engineered with state-of-the-art technology, providing real-time monitoring and diagnostics for critical machinery. Key features include:

1. High-Precision Sensors: The BENTLY Nevada integrates high-accuracy sensors that measure vibration, temperature, and other vital parameters, ensuring precise condition monitoring of rotating equipment.

2. Robust Data Acquisition: With its advanced data acquisition capabilities, the BENTLY Nevada can capture and analyze data from multiple sources simultaneously, providing a holistic view of equipment performance.

3. Intuitive User Interface: The model features an intuitive interface that allows operators to easily navigate through monitoring parameters, diagnostics, and reporting tools, streamlining operations and facilitating quicker decision-making.

4. Flexible Configuration: The BENTLY Nevada supports a variety of configurations, making it adaptable to different applications and environments, from power generation to oil and gas facilities.

5. Reliable Communication Protocols: Equipped with various communication options, including Ethernet and serial protocols, the BENTLY Nevada ensures seamless integration with existing systems and networks.

Usage Scenarios

The BENTLY Nevada is ideal for a wide range of industrial applications. In power generation facilities, it can monitor turbine performance, identifying potential issues before they escalate into costly downtime. In the oil and gas sector, the BENTLY Nevada enhances the reliability of critical processes by providing real-time insights into equipment health, thereby minimizing the risk of failures. Furthermore, it is invaluable in manufacturing plants, where it aids in the monitoring of motors, pumps, and other rotating machinery to ensure optimal operation.

Comparison with Other Models

When comparing the BENTLY Nevada with other models within the BENTLY lineup, such as the BENTLY 3500 series, it becomes clear that the Nevada stands out due to its advanced features and versatility. While models like the BENTLY 3500/20 and BENTLY 3500/40M are excellent for specific applications, the BENTLY Nevada offers a broader range of monitoring capabilities, making it more suitable for complex industrial environments.

Additionally, the BENTLY 3500/53 and BENTLY 3300/20 are excellent in their own right, focusing on particular aspects of condition monitoring. However, the BENTLY Nevada combines various functionalities into a single robust system, reducing the need for multiple devices and simplifying maintenance and operation.

Related Models

For those interested in exploring the breadth of BENTLY automation products, consider the following related models: BENTLY 3500/20 125744-02, BENTLY 3500/45 176449-04, BENTLY 350

The above parameters are for reference only. Please contact our technical team for precise selection.

BENTLY Nevada has long been recognized as a leader in the realm of industrial automation products, and the BENTLY Nevada model is no exception. Designed to enhance operational efficiency and reliability, this advanced monitoring system offers a comprehensive suite of features tailored for demanding industrial environments.

Key Technical Features

The BENTLY Nevada is engineered with state-of-the-art technology, providing real-time monitoring and diagnostics for critical machinery. Key features include:

1. High-Precision Sensors: The BENTLY Nevada integrates high-accuracy sensors that measure vibration, temperature, and other vital parameters, ensuring precise condition monitoring of rotating equipment.

2. Robust Data Acquisition: With its advanced data acquisition capabilities, the BENTLY Nevada can capture and analyze data from multiple sources simultaneously, providing a holistic view of equipment performance.

3. Intuitive User Interface: The model features an intuitive interface that allows operators to easily navigate through monitoring parameters, diagnostics, and reporting tools, streamlining operations and facilitating quicker decision-making.

4. Flexible Configuration: The BENTLY Nevada supports a variety of configurations, making it adaptable to different applications and environments, from power generation to oil and gas facilities.

5. Reliable Communication Protocols: Equipped with various communication options, including Ethernet and serial protocols, the BENTLY Nevada ensures seamless integration with existing systems and networks.

Usage Scenarios

The BENTLY Nevada is ideal for a wide range of industrial applications. In power generation facilities, it can monitor turbine performance, identifying potential issues before they escalate into costly downtime. In the oil and gas sector, the BENTLY Nevada enhances the reliability of critical processes by providing real-time insights into equipment health, thereby minimizing the risk of failures. Furthermore, it is invaluable in manufacturing plants, where it aids in the monitoring of motors, pumps, and other rotating machinery to ensure optimal operation.

Comparison with Other Models

When comparing the BENTLY Nevada with other models within the BENTLY lineup, such as the BENTLY 3500 series, it becomes clear that the Nevada stands out due to its advanced features and versatility. While models like the BENTLY 3500/20 and BENTLY 3500/40M are excellent for specific applications, the BENTLY Nevada offers a broader range of monitoring capabilities, making it more suitable for complex industrial environments.

Additionally, the BENTLY 3500/53 and BENTLY 3300/20 are excellent in their own right, focusing on particular aspects of condition monitoring. However, the BENTLY Nevada combines various functionalities into a single robust system, reducing the need for multiple devices and simplifying maintenance and operation.

Related Models

For those interested in exploring the breadth of BENTLY automation products, consider the following related models: BENTLY 3500/20 125744-02, BENTLY 3500/45 176449-04, BENTLY 350

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.