BENTLY Nevada 1900/65A Advanced Control Module for Industrial Automation

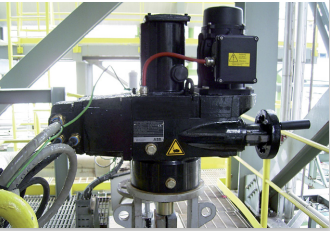

Introducing the BENTLY Nevada 1900/65A, a cornerstone of BENTLY’s renowned lineup of automation products, designed to deliver exceptional performance and reliability in industrial applications. This advanced monitoring system is engineered for seamless integration into your existing infrastructure, providing unparalleled insight into machinery health and performance.

Key Technical Features:

The BENTLY Nevada 1900/65A is equipped with state-of-the-art technology that sets it apart in the field of condition monitoring. It features a robust sensor architecture capable of capturing a wide range of vibration data, ensuring real-time analysis and reporting. With its high-speed data acquisition capabilities, the 1900/65A can monitor multiple channels simultaneously, allowing for a comprehensive overview of machine dynamics. The unit is designed to withstand harsh operating environments, making it suitable for a variety of industrial applications. Additionally, its intuitive user interface streamlines configuration and data visualization, empowering operators to make informed decisions swiftly.

The BENTLY Nevada 1900/65A supports various communication protocols, ensuring compatibility with a multitude of control systems. This versatility makes it an ideal choice for facilities looking to enhance their automation capabilities without overhauling their existing setups. The unit also features advanced diagnostics and predictive maintenance tools, which can significantly reduce downtime and maintenance costs.

Usage Scenarios:

The BENTLY Nevada 1900/65A is particularly well-suited for industries such as oil and gas, power generation, and manufacturing. In the oil and gas sector, it can be employed to monitor rotating equipment, such as pumps and compressors, providing early warnings of potential failures. In power generation, this model ensures optimal performance of turbines and generators by monitoring their vibrations and operational conditions.

Manufacturers can leverage the BENTLY Nevada 1900/65A to enhance the reliability of critical machinery, such as CNC machines and conveyors, by ensuring they operate within specified parameters. Its ability to provide real-time data enhances productivity and efficiency, making it a valuable asset to any industrial operation.

Comparison with Other Models:

When compared to other models in the BENTLY automation products range, such as the BENTLY 3500 series, the 1900/65A stands out for its advanced sensor technology and data acquisition capabilities. While the 3500 series is renowned for its versatility across different applications, the 1900/65A offers specific enhancements in vibration monitoring, making it a superior choice for industries requiring precise condition monitoring.

Additionally, the BENTLY 3500/45 and 3500/50 models provide excellent condition monitoring but may not match the comprehensive capabilities of the 1900/65A in terms of data processing speed and diagnostics. For those looking for a compact solution, the BENTLY 3300 series offers great features but lacks the advanced functionalities of the 1900/65A, particularly in high-performance environments.

Related Models:

For those exploring options within the BENTLY product lineup, consider the following related models: BENTLY

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The BENTLY Nevada 1900/65A is equipped with state-of-the-art technology that sets it apart in the field of condition monitoring. It features a robust sensor architecture capable of capturing a wide range of vibration data, ensuring real-time analysis and reporting. With its high-speed data acquisition capabilities, the 1900/65A can monitor multiple channels simultaneously, allowing for a comprehensive overview of machine dynamics. The unit is designed to withstand harsh operating environments, making it suitable for a variety of industrial applications. Additionally, its intuitive user interface streamlines configuration and data visualization, empowering operators to make informed decisions swiftly.

The BENTLY Nevada 1900/65A supports various communication protocols, ensuring compatibility with a multitude of control systems. This versatility makes it an ideal choice for facilities looking to enhance their automation capabilities without overhauling their existing setups. The unit also features advanced diagnostics and predictive maintenance tools, which can significantly reduce downtime and maintenance costs.

Usage Scenarios:

The BENTLY Nevada 1900/65A is particularly well-suited for industries such as oil and gas, power generation, and manufacturing. In the oil and gas sector, it can be employed to monitor rotating equipment, such as pumps and compressors, providing early warnings of potential failures. In power generation, this model ensures optimal performance of turbines and generators by monitoring their vibrations and operational conditions.

Manufacturers can leverage the BENTLY Nevada 1900/65A to enhance the reliability of critical machinery, such as CNC machines and conveyors, by ensuring they operate within specified parameters. Its ability to provide real-time data enhances productivity and efficiency, making it a valuable asset to any industrial operation.

Comparison with Other Models:

When compared to other models in the BENTLY automation products range, such as the BENTLY 3500 series, the 1900/65A stands out for its advanced sensor technology and data acquisition capabilities. While the 3500 series is renowned for its versatility across different applications, the 1900/65A offers specific enhancements in vibration monitoring, making it a superior choice for industries requiring precise condition monitoring.

Additionally, the BENTLY 3500/45 and 3500/50 models provide excellent condition monitoring but may not match the comprehensive capabilities of the 1900/65A in terms of data processing speed and diagnostics. For those looking for a compact solution, the BENTLY 3300 series offers great features but lacks the advanced functionalities of the 1900/65A, particularly in high-performance environments.

Related Models:

For those exploring options within the BENTLY product lineup, consider the following related models: BENTLY

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.