BENTLY Bently Nevada 127610-01 Advanced Control Module

Introducing the BENTLY Bently Nevada 127610-01, a cutting-edge solution designed to elevate the reliability and efficiency of your industrial operations. Renowned for its precision and durability, this model is an essential component in the realm of condition monitoring and predictive maintenance. With its advanced technology, the BENTLY Nevada 127610-01 offers key technical features tailored to meet the demands of modern industries.

Key Technical Features:

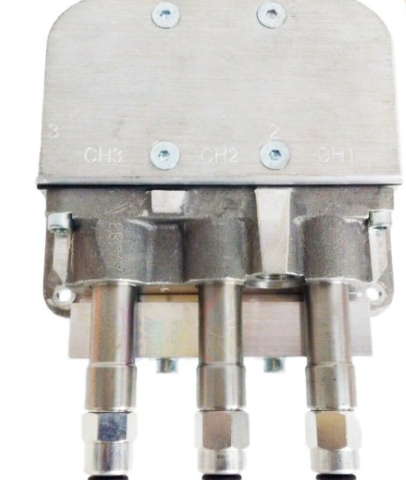

The BENTLY Bently Nevada 127610-01 boasts an array of impressive specifications that set it apart from competitors. It features a high-performance modular architecture that allows for scalability and customization based on specific application requirements. Incorporating state-of-the-art sensors, the unit excels in vibration monitoring, temperature measurement, and other critical parameters essential for machinery health assessment. The device supports multiple input channels, enabling simultaneous monitoring of various assets, thereby maximizing efficiency. Furthermore, its user-friendly interface simplifies data interpretation and analysis, allowing for quick decision-making.

Usage Scenarios:

The versatility of the BENTLY Bently Nevada 127610-01 makes it suitable for a multitude of industrial applications. It is particularly effective in environments where rotating machinery is prevalent, such as oil and gas, power generation, and manufacturing sectors. For instance, in a power plant, this model can monitor turbine vibrations, ensuring optimal performance and preventing unplanned downtimes. In the oil and gas industry, it can track compressor health, providing crucial data to prevent costly failures. Its ability to integrate seamlessly with existing BENTLY automation products further enhances its functionality, making it a preferred choice among engineers and maintenance professionals.

Comparison with Other Models:

When comparing the BENTLY Nevada 127610-01 to other models within the BENTLY range, such as the BENTLY 3500/20 125744-02 and BENTLY 3500/50, several distinctions emerge. The 127610-01 offers superior multi-channel capabilities, making it an ideal choice for applications requiring comprehensive monitoring. In contrast, the BENTLY 3500/40M is optimized for specific machinery types, while the BENTLY 3500/22M focuses on temperature measurements. The BENTLY Nevada 127610-01 stands out for its versatility and adaptability, catering to a broader spectrum of industrial needs.

Related Models:

For those exploring BENTLY automation products, consider these related models: the BENTLY 3500/15, known for its reliability in basic monitoring tasks; the BENTLY 3500/40M, which excels in machinery protection; and the BENTLY 3500/92, designed for comprehensive system diagnostics. Other noteworthy models include the BENTLY 3300/20-12-01-03-00-00, which offers advanced vibration analysis; and the BENTLY 136719-01, recognized for its efficiency in data collection. The BENTLY 3500/53 is another model that complements

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The BENTLY Bently Nevada 127610-01 boasts an array of impressive specifications that set it apart from competitors. It features a high-performance modular architecture that allows for scalability and customization based on specific application requirements. Incorporating state-of-the-art sensors, the unit excels in vibration monitoring, temperature measurement, and other critical parameters essential for machinery health assessment. The device supports multiple input channels, enabling simultaneous monitoring of various assets, thereby maximizing efficiency. Furthermore, its user-friendly interface simplifies data interpretation and analysis, allowing for quick decision-making.

Usage Scenarios:

The versatility of the BENTLY Bently Nevada 127610-01 makes it suitable for a multitude of industrial applications. It is particularly effective in environments where rotating machinery is prevalent, such as oil and gas, power generation, and manufacturing sectors. For instance, in a power plant, this model can monitor turbine vibrations, ensuring optimal performance and preventing unplanned downtimes. In the oil and gas industry, it can track compressor health, providing crucial data to prevent costly failures. Its ability to integrate seamlessly with existing BENTLY automation products further enhances its functionality, making it a preferred choice among engineers and maintenance professionals.

Comparison with Other Models:

When comparing the BENTLY Nevada 127610-01 to other models within the BENTLY range, such as the BENTLY 3500/20 125744-02 and BENTLY 3500/50, several distinctions emerge. The 127610-01 offers superior multi-channel capabilities, making it an ideal choice for applications requiring comprehensive monitoring. In contrast, the BENTLY 3500/40M is optimized for specific machinery types, while the BENTLY 3500/22M focuses on temperature measurements. The BENTLY Nevada 127610-01 stands out for its versatility and adaptability, catering to a broader spectrum of industrial needs.

Related Models:

For those exploring BENTLY automation products, consider these related models: the BENTLY 3500/15, known for its reliability in basic monitoring tasks; the BENTLY 3500/40M, which excels in machinery protection; and the BENTLY 3500/92, designed for comprehensive system diagnostics. Other noteworthy models include the BENTLY 3300/20-12-01-03-00-00, which offers advanced vibration analysis; and the BENTLY 136719-01, recognized for its efficiency in data collection. The BENTLY 3500/53 is another model that complements

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.