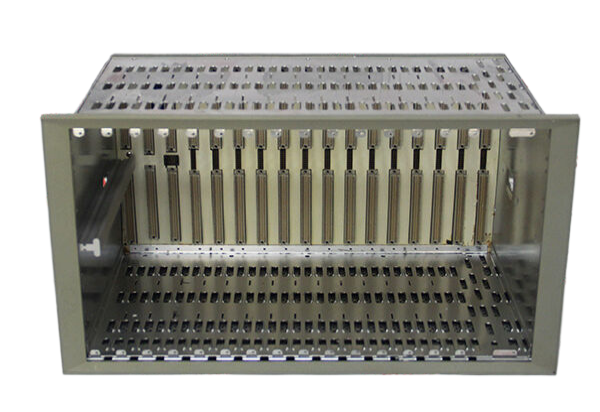

BENTLY 3500/70M Vibration Monitoring Module

Introducing the BENTLY 3500/70M, the pinnacle of reliability and precision in condition monitoring systems designed for the most demanding industrial environments. Engineered by BENTLY, a leader in automation products, the 3500/70M stands out with its advanced features that ensure optimal performance and safety in your operations.

Key Technical Features:

The BENTLY 3500/70M is equipped with sophisticated technology designed for comprehensive vibration monitoring. Its advanced signal processing capabilities allow it to detect subtle changes in machinery behavior, making it indispensable for predictive maintenance. The device features a 4-20 mA output, which is ideal for seamless integration with existing control systems. Its high-resolution sensors provide accurate data collection, while the modular design allows for easy upgrades and maintenance.

The 3500/70M supports a wide range of input types, including proximity probes, accelerometers, and velocity sensors, making it versatile for numerous applications. Additionally, the unit is designed for high reliability, featuring built-in diagnostics to ensure continuous operation. With a temperature range that supports extreme industrial conditions, the BENTLY 3500/70M is built to last, reducing downtime and maintenance costs.

Usage Scenarios:

The BENTLY 3500/70M is perfect for various industrial applications, including power generation, oil and gas, and manufacturing. In power plants, it can monitor turbine vibrations, ensuring that any potential issues are detected early to prevent costly failures. In the oil and gas sector, it plays a crucial role in monitoring pumps and compressors, facilitating effective predictive maintenance strategies. Manufacturing facilities benefit from its ability to monitor rotating machinery, helping to extend equipment life and improve overall productivity.

Comparison with Other Models:

When compared to other models in the BENTLY lineup, such as the BENTLY 3500/20 and 3500/45, the 3500/70M offers enhanced features specific to vibration monitoring. While the 3500/20 is excellent for basic monitoring needs, the 3500/70M provides deeper insights and advanced diagnostics, making it more suitable for complex machinery. Similarly, the 3500/45 is designed for machinery protection, but the 3500/70M excels in predictive maintenance with its superior data analysis capabilities.

Related Models:

For those exploring alternatives or complementary devices, the following BENTLY models are noteworthy: BENTLY 3500/20 125744-02, BENTLY 3500/40M, BENTLY 3500/50, BENTLY 3500/34, BENTLY 3500/42M, BENTLY 3500/22M, BENTLY 3500/93 P/N:135785-02, BENTLY 3500/25, BENTLY 3500/15, and BENTLY 3500/70M 133819-02. Each of these models serves specific monitoring or protection needs

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The BENTLY 3500/70M is equipped with sophisticated technology designed for comprehensive vibration monitoring. Its advanced signal processing capabilities allow it to detect subtle changes in machinery behavior, making it indispensable for predictive maintenance. The device features a 4-20 mA output, which is ideal for seamless integration with existing control systems. Its high-resolution sensors provide accurate data collection, while the modular design allows for easy upgrades and maintenance.

The 3500/70M supports a wide range of input types, including proximity probes, accelerometers, and velocity sensors, making it versatile for numerous applications. Additionally, the unit is designed for high reliability, featuring built-in diagnostics to ensure continuous operation. With a temperature range that supports extreme industrial conditions, the BENTLY 3500/70M is built to last, reducing downtime and maintenance costs.

Usage Scenarios:

The BENTLY 3500/70M is perfect for various industrial applications, including power generation, oil and gas, and manufacturing. In power plants, it can monitor turbine vibrations, ensuring that any potential issues are detected early to prevent costly failures. In the oil and gas sector, it plays a crucial role in monitoring pumps and compressors, facilitating effective predictive maintenance strategies. Manufacturing facilities benefit from its ability to monitor rotating machinery, helping to extend equipment life and improve overall productivity.

Comparison with Other Models:

When compared to other models in the BENTLY lineup, such as the BENTLY 3500/20 and 3500/45, the 3500/70M offers enhanced features specific to vibration monitoring. While the 3500/20 is excellent for basic monitoring needs, the 3500/70M provides deeper insights and advanced diagnostics, making it more suitable for complex machinery. Similarly, the 3500/45 is designed for machinery protection, but the 3500/70M excels in predictive maintenance with its superior data analysis capabilities.

Related Models:

For those exploring alternatives or complementary devices, the following BENTLY models are noteworthy: BENTLY 3500/20 125744-02, BENTLY 3500/40M, BENTLY 3500/50, BENTLY 3500/34, BENTLY 3500/42M, BENTLY 3500/22M, BENTLY 3500/93 P/N:135785-02, BENTLY 3500/25, BENTLY 3500/15, and BENTLY 3500/70M 133819-02. Each of these models serves specific monitoring or protection needs

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.