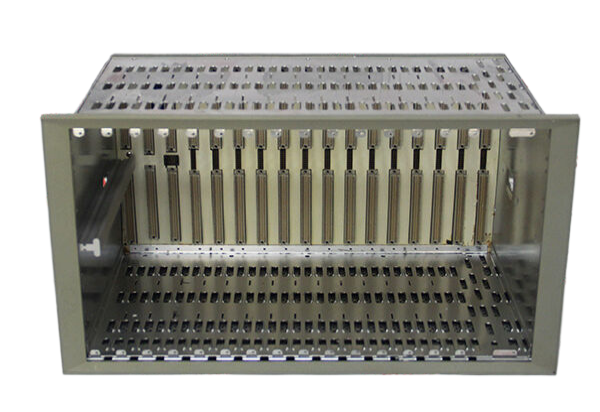

BENTLY 1900/65A (167699-02)

Introducing the BENTLY 1900/65A, a cutting-edge solution in the realm of industrial automation and monitoring. Designed for performance and reliability, the BENTLY 1900/65A is engineered to ensure optimal operation and protection of critical machinery. This advanced model boasts an array of key technical features that distinguish it from its counterparts, making it an indispensable asset for industries requiring precision and dependability.

### Key Technical Features

The BENTLY 1900/65A is equipped with state-of-the-art technology, including high-speed data acquisition capabilities, allowing for real-time monitoring of equipment conditions. With its robust design, it is capable of supporting a wide range of sensors and transducers, making it adaptable to various applications. The model features a user-friendly interface, enabling seamless integration with existing systems while providing comprehensive diagnostics to help users identify potential issues before they escalate.

One of the standout features of the BENTLY 1900/65A is its advanced signal processing capabilities. This model excels in vibration analysis, temperature monitoring, and overall equipment health assessment, providing users with the insights needed to maintain operational efficiency. Additionally, its modular design allows for easy upgrades and expansions, ensuring that the system can grow alongside your operational needs.

### Usage Scenarios

The BENTLY 1900/65A excels in various industrial applications, particularly in sectors such as oil and gas, power generation, and manufacturing. In oil and gas, it can be employed for monitoring pumps, compressors, and turbines, ensuring they operate within safe parameters. In power generation plants, the BENTLY 1900/65A provides critical insights into generator and turbine health, enabling predictive maintenance that minimizes downtime.

Moreover, in manufacturing environments, this model enhances process control and machine reliability, leading to increased productivity. By utilizing the BENTLY 1900/65A, companies can streamline their operations, reduce maintenance costs, and improve overall asset management.

### Comparison with Other Models

When compared to other models in the BENTLY lineup, such as the BENTLY 3500/20 and the BENTLY 3500/40M, the BENTLY 1900/65A stands out due to its enhanced data processing capabilities and user-centric design. While the BENTLY 3500 series is well-regarded for its reliability, the 1900/65A offers superior integration options and more advanced analytics features, making it a preferred choice for organizations looking for the latest in monitoring technology.

Additionally, while the BENTLY 3500/25 provides solid performance, the 1900/65A takes it a step further with enhanced modularity and adaptability, catering to a broader range of industrial applications. For those familiar with the BENTLY Nevada and BENTLY 3500/50, the BENTLY 1900/65A offers a more streamlined approach to data management, ensuring that users have access to the information they need, when they

The above parameters are for reference only. Please contact our technical team for precise selection.

### Key Technical Features

The BENTLY 1900/65A is equipped with state-of-the-art technology, including high-speed data acquisition capabilities, allowing for real-time monitoring of equipment conditions. With its robust design, it is capable of supporting a wide range of sensors and transducers, making it adaptable to various applications. The model features a user-friendly interface, enabling seamless integration with existing systems while providing comprehensive diagnostics to help users identify potential issues before they escalate.

One of the standout features of the BENTLY 1900/65A is its advanced signal processing capabilities. This model excels in vibration analysis, temperature monitoring, and overall equipment health assessment, providing users with the insights needed to maintain operational efficiency. Additionally, its modular design allows for easy upgrades and expansions, ensuring that the system can grow alongside your operational needs.

### Usage Scenarios

The BENTLY 1900/65A excels in various industrial applications, particularly in sectors such as oil and gas, power generation, and manufacturing. In oil and gas, it can be employed for monitoring pumps, compressors, and turbines, ensuring they operate within safe parameters. In power generation plants, the BENTLY 1900/65A provides critical insights into generator and turbine health, enabling predictive maintenance that minimizes downtime.

Moreover, in manufacturing environments, this model enhances process control and machine reliability, leading to increased productivity. By utilizing the BENTLY 1900/65A, companies can streamline their operations, reduce maintenance costs, and improve overall asset management.

### Comparison with Other Models

When compared to other models in the BENTLY lineup, such as the BENTLY 3500/20 and the BENTLY 3500/40M, the BENTLY 1900/65A stands out due to its enhanced data processing capabilities and user-centric design. While the BENTLY 3500 series is well-regarded for its reliability, the 1900/65A offers superior integration options and more advanced analytics features, making it a preferred choice for organizations looking for the latest in monitoring technology.

Additionally, while the BENTLY 3500/25 provides solid performance, the 1900/65A takes it a step further with enhanced modularity and adaptability, catering to a broader range of industrial applications. For those familiar with the BENTLY Nevada and BENTLY 3500/50, the BENTLY 1900/65A offers a more streamlined approach to data management, ensuring that users have access to the information they need, when they

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.