ABB IRB 7602-33HAC058991-005 3HAC024776-001 3HAC058990-005 IRB660 3HAC043072-001003 Advanced Industrial Robot System for Enhanced Manufacturing Efficiency

Introducing the ABB IRB 7602-33HAC058991-005, a powerhouse in the realm of industrial automation. This multi-purpose robotic arm is engineered to enhance productivity across various applications, making it a versatile addition to any manufacturing setup. With its advanced technology and robust design, the IRB 7602 is perfect for tasks ranging from assembly and material handling to packaging and welding.

Key technical features of the ABB IRB 7602 include a high payload capacity of up to 33 kg, allowing it to handle heavier components with ease. This model boasts a reach of 2.5 meters, providing ample coverage for large workspaces. The IRB 7602 is equipped with the latest ABB motion control technology, ensuring precision and repeatability in every operation. Its compact design minimizes the footprint in your workspace while maximizing efficiency. Additionally, the robot features integrated safety protocols, ensuring a secure working environment alongside human operators.

The ABB IRB 7602 is designed to thrive in various usage scenarios. In automotive manufacturing, it can efficiently assemble components, improving throughput while maintaining high-quality standards. For electronics assembly, the robot’s precision ensures the delicate handling of small parts, minimizing the risk of damage. In packaging and palletizing applications, the IRB 7602’s speed and accuracy streamline processes, reducing labor costs and increasing production rates. The flexibility of this model makes it suitable for industries ranging from pharmaceuticals to consumer goods, adapting to multiple tasks without requiring extensive reprogramming.

When comparing the ABB IRB 7602 with other models such as the ABB IRB 660 or IRB 2400, the advantages become clear. While the IRB 660 offers a compact design for tighter workspaces, the IRB 7602’s higher payload capacity and extended reach make it a superior choice for heavier applications. The IRB 2400, on the other hand, is known for its versatility and speed, but the IRB 7602 surpasses it in handling larger components and providing a broader operational range. This makes the IRB 7602 an ideal solution for manufacturers looking to enhance their automation capabilities without sacrificing performance.

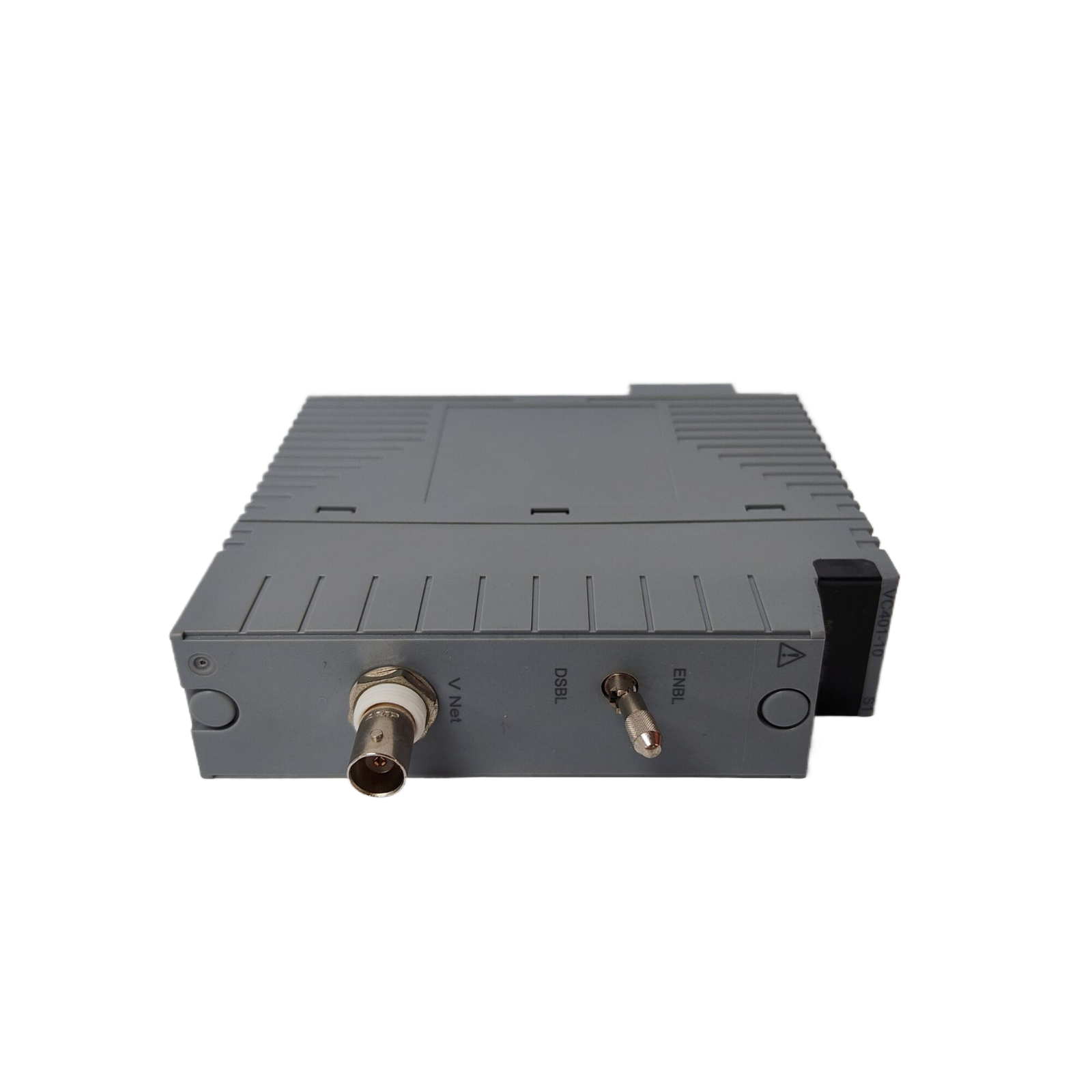

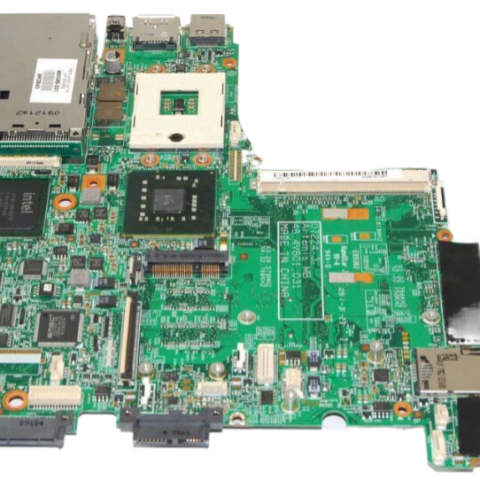

For those exploring ABB automation products, the IRB 7602-33HAC058991-005 is complemented by a range of related models that cater to various needs. The ABB IRB 2600, for example, is another robust option with a slightly lower payload capacity but excels in fast-paced environments. The ABB IRB 140 Series offers a compact and agile solution for smaller tasks, while the ABB IRB 2400/1403/CR3 is perfect for intricate applications requiring high precision. Additionally, models like the ABB 07DC91 and ABB SDCS-PIN-51 provide integration capabilities for broader automation systems, enhancing the IRB 7602’s functionality.

Other noteworthy models include the ABB TU532-XC, known for its powerful I/O capabilities, and the ABB ACS880-01-246A-3, which offers advanced control solutions for motor drives. The ABB PM511V16 and ABB 3HAC027569-001 models are also essential components for those looking to build a comprehensive automation system. With the IRB 7602 at the core, these models create a synergistic effect, ensuring your operations run smoothly and efficiently.

In conclusion, the ABB IRB 7602-33HAC058991-005, with its high payload capacity, extended reach, and superior precision, stands out as a premier choice for businesses seeking to elevate their automation processes. Its adaptability across various industries, combined with its advanced technical features, makes it a valuable asset for any manufacturing operation. Explore the potential of ABB automation products today and transform your production line into a beacon of efficiency and innovation.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key technical features of the ABB IRB 7602 include a high payload capacity of up to 33 kg, allowing it to handle heavier components with ease. This model boasts a reach of 2.5 meters, providing ample coverage for large workspaces. The IRB 7602 is equipped with the latest ABB motion control technology, ensuring precision and repeatability in every operation. Its compact design minimizes the footprint in your workspace while maximizing efficiency. Additionally, the robot features integrated safety protocols, ensuring a secure working environment alongside human operators.

The ABB IRB 7602 is designed to thrive in various usage scenarios. In automotive manufacturing, it can efficiently assemble components, improving throughput while maintaining high-quality standards. For electronics assembly, the robot’s precision ensures the delicate handling of small parts, minimizing the risk of damage. In packaging and palletizing applications, the IRB 7602’s speed and accuracy streamline processes, reducing labor costs and increasing production rates. The flexibility of this model makes it suitable for industries ranging from pharmaceuticals to consumer goods, adapting to multiple tasks without requiring extensive reprogramming.

When comparing the ABB IRB 7602 with other models such as the ABB IRB 660 or IRB 2400, the advantages become clear. While the IRB 660 offers a compact design for tighter workspaces, the IRB 7602’s higher payload capacity and extended reach make it a superior choice for heavier applications. The IRB 2400, on the other hand, is known for its versatility and speed, but the IRB 7602 surpasses it in handling larger components and providing a broader operational range. This makes the IRB 7602 an ideal solution for manufacturers looking to enhance their automation capabilities without sacrificing performance.

For those exploring ABB automation products, the IRB 7602-33HAC058991-005 is complemented by a range of related models that cater to various needs. The ABB IRB 2600, for example, is another robust option with a slightly lower payload capacity but excels in fast-paced environments. The ABB IRB 140 Series offers a compact and agile solution for smaller tasks, while the ABB IRB 2400/1403/CR3 is perfect for intricate applications requiring high precision. Additionally, models like the ABB 07DC91 and ABB SDCS-PIN-51 provide integration capabilities for broader automation systems, enhancing the IRB 7602’s functionality.

Other noteworthy models include the ABB TU532-XC, known for its powerful I/O capabilities, and the ABB ACS880-01-246A-3, which offers advanced control solutions for motor drives. The ABB PM511V16 and ABB 3HAC027569-001 models are also essential components for those looking to build a comprehensive automation system. With the IRB 7602 at the core, these models create a synergistic effect, ensuring your operations run smoothly and efficiently.

In conclusion, the ABB IRB 7602-33HAC058991-005, with its high payload capacity, extended reach, and superior precision, stands out as a premier choice for businesses seeking to elevate their automation processes. Its adaptability across various industries, combined with its advanced technical features, makes it a valuable asset for any manufacturing operation. Explore the potential of ABB automation products today and transform your production line into a beacon of efficiency and innovation.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.