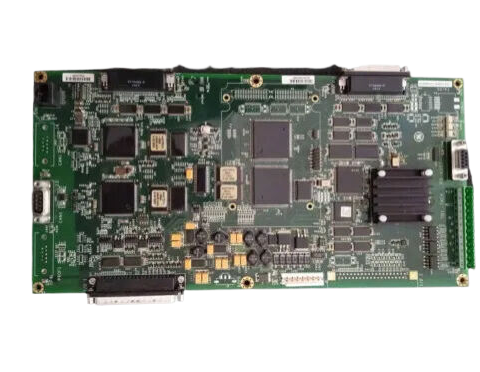

GE VMIC VMIVME-3128

Introducing the GE VMIC, a cutting-edge solution in the realm of industrial automation, designed to enhance operational efficiency and reliability in a wide array of applications. As part of GE's illustrious lineup of automation products, the VMIC stands out with its impressive technical features and versatility, ensuring that it meets the demanding needs of modern industry.

Key Technical Features:

The GE VMIC boasts a robust architecture that supports advanced automation functionalities. It is equipped with a high-performance processor, enabling rapid data processing and real-time control. The VMIC also features a modular design that allows for easy integration with various GE automation products and other systems, making it ideal for complex industrial environments. Its extensive I/O capabilities support a wide range of input and output types, ensuring seamless communication with external devices and sensors.

Additionally, the GE VMIC offers extensive connectivity options, including Ethernet, serial, and fieldbus protocols, ensuring that it can be easily incorporated into existing networks. With built-in diagnostics and status monitoring, users can quickly identify and troubleshoot issues, reducing downtime and enhancing productivity.

Usage Scenarios:

The GE VMIC is designed for diverse industrial applications, including manufacturing, process control, and data acquisition. In a manufacturing setting, the VMIC can be utilized to automate assembly lines, monitor machinery performance, and optimize resource allocation. In process control environments, it ensures precise regulation of variables such as temperature, pressure, and flow, enhancing product quality and consistency.

Moreover, the GE VMIC is well-suited for data-driven industries, where it can function as a central hub for collecting and analyzing performance metrics. Its ability to integrate with IoT devices allows for advanced analytics and predictive maintenance, further driving operational efficiency.

Comparison with Other Models:

When comparing the GE VMIC to other models within the GE family, such as the GE SR750 and GE IS200DSPXH2DBD, the VMIC offers superior processing power and flexibility. While the GE SR750 is tailored for specific applications with limited I/O capabilities, the VMIC provides a broader range of options, making it suitable for more complex and demanding tasks.

In contrast to older models like the GE IC3600A0AHIC or GE IC200CPU005, which may lack the advanced connectivity features of the VMIC, users will find that the VMIC’s modern architecture allows for easier integration into contemporary industrial networks. Furthermore, when placed alongside models like the GE IS200JPDMG1ADC and GE IS200EDFFH1ABA, the VMIC's modular design and enhanced diagnostics provide a distinct advantage in terms of scalability and system maintenance.

Related Models:

The GE VMIC is part of a comprehensive portfolio of GE automation products, which includes notable models such as the GE IC660BBA020, GE IC693APU301, GE IS200VTURH1BAC, GE IC695CPE310-ABAH, and GE DS200DDTBG2A. Each of these models offers unique functionalities, catering to specific industrial

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE VMIC boasts a robust architecture that supports advanced automation functionalities. It is equipped with a high-performance processor, enabling rapid data processing and real-time control. The VMIC also features a modular design that allows for easy integration with various GE automation products and other systems, making it ideal for complex industrial environments. Its extensive I/O capabilities support a wide range of input and output types, ensuring seamless communication with external devices and sensors.

Additionally, the GE VMIC offers extensive connectivity options, including Ethernet, serial, and fieldbus protocols, ensuring that it can be easily incorporated into existing networks. With built-in diagnostics and status monitoring, users can quickly identify and troubleshoot issues, reducing downtime and enhancing productivity.

Usage Scenarios:

The GE VMIC is designed for diverse industrial applications, including manufacturing, process control, and data acquisition. In a manufacturing setting, the VMIC can be utilized to automate assembly lines, monitor machinery performance, and optimize resource allocation. In process control environments, it ensures precise regulation of variables such as temperature, pressure, and flow, enhancing product quality and consistency.

Moreover, the GE VMIC is well-suited for data-driven industries, where it can function as a central hub for collecting and analyzing performance metrics. Its ability to integrate with IoT devices allows for advanced analytics and predictive maintenance, further driving operational efficiency.

Comparison with Other Models:

When comparing the GE VMIC to other models within the GE family, such as the GE SR750 and GE IS200DSPXH2DBD, the VMIC offers superior processing power and flexibility. While the GE SR750 is tailored for specific applications with limited I/O capabilities, the VMIC provides a broader range of options, making it suitable for more complex and demanding tasks.

In contrast to older models like the GE IC3600A0AHIC or GE IC200CPU005, which may lack the advanced connectivity features of the VMIC, users will find that the VMIC’s modern architecture allows for easier integration into contemporary industrial networks. Furthermore, when placed alongside models like the GE IS200JPDMG1ADC and GE IS200EDFFH1ABA, the VMIC's modular design and enhanced diagnostics provide a distinct advantage in terms of scalability and system maintenance.

Related Models:

The GE VMIC is part of a comprehensive portfolio of GE automation products, which includes notable models such as the GE IC660BBA020, GE IC693APU301, GE IS200VTURH1BAC, GE IC695CPE310-ABAH, and GE DS200DDTBG2A. Each of these models offers unique functionalities, catering to specific industrial

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.