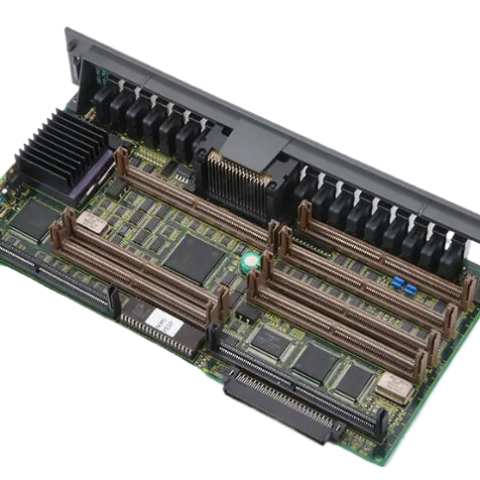

GE IS200TPROH1BCB Mark VI Board for Turbine Control

Introducing the GE IS200TPROH1BCB, a cutting-edge component in the world of GE automation products that is designed to elevate your control systems to the next level. This model is engineered for high-performance applications, making it an ideal choice for industries requiring robust and reliable automation solutions.

Key Technical Features

The GE IS200TPROH1BCB is a powerful turbine control module that boasts several key features that enhance its operational efficiency. It supports advanced control strategies and offers superior processing capabilities, ensuring fast and precise control of turbine operations. This model is equipped with extensive diagnostic capabilities, allowing for real-time monitoring and troubleshooting to maintain optimal performance. The design is modular, facilitating easy integration with existing systems and providing scalability for future expansion. The IS200TPROH1BCB also features multiple communication protocols, ensuring compatibility with a wide range of GE automation products and third-party devices. With its rugged construction and temperature-resistant components, it is built to withstand harsh industrial environments.

Usage Scenarios

The versatility of the GE IS200TPROH1BCB makes it suitable for various applications in industries such as power generation, oil and gas, and water treatment. In power plants, it can be utilized for controlling steam or gas turbines, optimizing performance while ensuring safety and reliability. In the oil and gas sector, it plays a crucial role in monitoring and controlling turbine-driven pumps and compressors, enhancing operational efficiency. Additionally, the IS200TPROH1BCB is ideal for water treatment facilities, where it helps in managing the equipment that drives the treatment process, ensuring consistent water quality and compliance with regulations.

Comparison with Other Models

When compared to similar GE automation products, such as the GE IS200TBCIH1BBC and GE IS200DSPXH1DBC, the IS200TPROH1BCB stands out for its advanced turbine control capabilities. While the IS200TBCIH1BBC is primarily focused on temperature sensing and control, the IS200TPROH1BCB offers comprehensive control of turbine operations, making it more suitable for industries relying heavily on turbine technology. In contrast to the IS200DSPXH1DBC, which is designed for digital signal processing applications, the IS200TPROH1BCB provides specialized features tailored for turbine management, making it a more targeted solution for specific requirements.

Related Models

In addition to the GE IS200TPROH1BCB, there are several related models worth mentioning for those looking to expand their automation solutions. The GE IS220PPROS1B offers advanced processing capabilities for various control applications, while the GE IS215UCVEH2AB provides enhanced connectivity features. For users focused on modularity, the GE IS220PAICH2A is an excellent choice. The GE IS200EPSMG2ADC is designed for power monitoring, whereas the GE IS220PRTDH1A specializes in temperature measurement. Other relevant models include the GE IS230SNIDH1A for signal processing, the GE IS200DSPXH1DBD for digital signal applications, and the GE DS200TCQAG1BHF for turbine control needs. Lastly, the GE IC693CPU374 and GE IC697MDL350 serve as robust controllers and I/O modules, respectively, that can be integrated with the IS200TPROH1BCB for a comprehensive automation solution.

In conclusion, the GE IS200TPROH1BCB is a top-tier choice for businesses seeking to optimize their turbine control systems. With its advanced features, versatility in various applications, and superior performance compared to other models, it stands out as a leading product in the GE automation products lineup. By choosing the IS200TPROH1BCB, you invest in reliability, efficiency, and future scalability, all backed by GE's renowned engineering expertise.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE IS200TPROH1BCB is a powerful turbine control module that boasts several key features that enhance its operational efficiency. It supports advanced control strategies and offers superior processing capabilities, ensuring fast and precise control of turbine operations. This model is equipped with extensive diagnostic capabilities, allowing for real-time monitoring and troubleshooting to maintain optimal performance. The design is modular, facilitating easy integration with existing systems and providing scalability for future expansion. The IS200TPROH1BCB also features multiple communication protocols, ensuring compatibility with a wide range of GE automation products and third-party devices. With its rugged construction and temperature-resistant components, it is built to withstand harsh industrial environments.

Usage Scenarios

The versatility of the GE IS200TPROH1BCB makes it suitable for various applications in industries such as power generation, oil and gas, and water treatment. In power plants, it can be utilized for controlling steam or gas turbines, optimizing performance while ensuring safety and reliability. In the oil and gas sector, it plays a crucial role in monitoring and controlling turbine-driven pumps and compressors, enhancing operational efficiency. Additionally, the IS200TPROH1BCB is ideal for water treatment facilities, where it helps in managing the equipment that drives the treatment process, ensuring consistent water quality and compliance with regulations.

Comparison with Other Models

When compared to similar GE automation products, such as the GE IS200TBCIH1BBC and GE IS200DSPXH1DBC, the IS200TPROH1BCB stands out for its advanced turbine control capabilities. While the IS200TBCIH1BBC is primarily focused on temperature sensing and control, the IS200TPROH1BCB offers comprehensive control of turbine operations, making it more suitable for industries relying heavily on turbine technology. In contrast to the IS200DSPXH1DBC, which is designed for digital signal processing applications, the IS200TPROH1BCB provides specialized features tailored for turbine management, making it a more targeted solution for specific requirements.

Related Models

In addition to the GE IS200TPROH1BCB, there are several related models worth mentioning for those looking to expand their automation solutions. The GE IS220PPROS1B offers advanced processing capabilities for various control applications, while the GE IS215UCVEH2AB provides enhanced connectivity features. For users focused on modularity, the GE IS220PAICH2A is an excellent choice. The GE IS200EPSMG2ADC is designed for power monitoring, whereas the GE IS220PRTDH1A specializes in temperature measurement. Other relevant models include the GE IS230SNIDH1A for signal processing, the GE IS200DSPXH1DBD for digital signal applications, and the GE DS200TCQAG1BHF for turbine control needs. Lastly, the GE IC693CPU374 and GE IC697MDL350 serve as robust controllers and I/O modules, respectively, that can be integrated with the IS200TPROH1BCB for a comprehensive automation solution.

In conclusion, the GE IS200TPROH1BCB is a top-tier choice for businesses seeking to optimize their turbine control systems. With its advanced features, versatility in various applications, and superior performance compared to other models, it stands out as a leading product in the GE automation products lineup. By choosing the IS200TPROH1BCB, you invest in reliability, efficiency, and future scalability, all backed by GE's renowned engineering expertise.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.