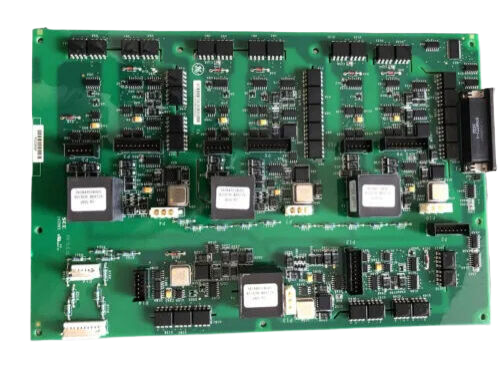

GE IC697CPU711 Processor Module High-Performance Control Core for Industrial Automation

Introducing the GE IC697CPU711, a cutting-edge programmable logic controller (PLC) designed to enhance automation processes across various industries. With its robust architecture and advanced processing capabilities, the IC697CPU711 is the ideal choice for manufacturers and industrial engineers seeking reliability, efficiency, and flexibility in their automation systems.

Key Technical Features:

The GE IC697CPU711 boasts a powerful 32-bit microprocessor, delivering high-speed execution of complex control algorithms and real-time data processing. With a memory capacity of 256 KB for user programs and an additional 256 KB for data storage, it accommodates extensive applications and large-scale automation tasks. The controller is equipped with a wide range of communication options, including built-in Ethernet and serial ports, enabling seamless integration with other GE automation products and third-party devices. The IC697CPU711 also supports multiple programming languages, including ladder logic, structured text, and function block diagrams, allowing engineers to choose the most suitable method for their applications.

Usage Scenarios:

The versatility of the GE IC697CPU711 makes it suitable for diverse applications ranging from manufacturing and process control to building management and transportation systems. In a manufacturing setting, it can effectively manage assembly lines, monitor production processes, and optimize machine performance. In process industries, the IC697CPU711 is capable of controlling complex systems such as chemical processing plants or water treatment facilities, where precision and real-time monitoring are crucial. Additionally, its robust communication capabilities allow for easy connectivity with supervisory systems, enhancing overall operational efficiency.

Comparison with Other Models:

When compared to other models within the GE family, such as the GE SR750 or GE IC693APU301, the IC697CPU711 stands out due to its superior processing power and memory capacity. While the GE SR750 offers advanced motion control features, the IC697CPU711 is more suited for applications requiring extensive logic processing and data handling. In contrast to the GE IC200CPU005, which is designed for simpler tasks, the IC697CPU711 is built to handle more complex automation challenges, making it a more versatile choice for engineers seeking a high-performance PLC.

Related Models:

The GE IC697CPU711 complements a wide range of other GE automation products, enhancing its functionality and adaptability. Some of these related models include:

1. GE SR750 – Known for its motion control capabilities.

2. GE IC697MDL740 – A versatile I/O module that pairs well with the IC697CPU711.

3. GE IS200DSFCG1AEB – A digital signal processing controller for specialized applications.

4. GE IC660BBA020 – A baseboard that supports various GE modules.

5. GE DS200DDTBG2A – A digital input terminal board compatible with the IC697 series.

6. GE IS200DSPXH2DBD – A dedicated signal processing module.

7. GE IC693APU301 – An advanced processing unit designed for complex applications.

8. GE IS200VTURH1BAC – A versatile controller

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE IC697CPU711 boasts a powerful 32-bit microprocessor, delivering high-speed execution of complex control algorithms and real-time data processing. With a memory capacity of 256 KB for user programs and an additional 256 KB for data storage, it accommodates extensive applications and large-scale automation tasks. The controller is equipped with a wide range of communication options, including built-in Ethernet and serial ports, enabling seamless integration with other GE automation products and third-party devices. The IC697CPU711 also supports multiple programming languages, including ladder logic, structured text, and function block diagrams, allowing engineers to choose the most suitable method for their applications.

Usage Scenarios:

The versatility of the GE IC697CPU711 makes it suitable for diverse applications ranging from manufacturing and process control to building management and transportation systems. In a manufacturing setting, it can effectively manage assembly lines, monitor production processes, and optimize machine performance. In process industries, the IC697CPU711 is capable of controlling complex systems such as chemical processing plants or water treatment facilities, where precision and real-time monitoring are crucial. Additionally, its robust communication capabilities allow for easy connectivity with supervisory systems, enhancing overall operational efficiency.

Comparison with Other Models:

When compared to other models within the GE family, such as the GE SR750 or GE IC693APU301, the IC697CPU711 stands out due to its superior processing power and memory capacity. While the GE SR750 offers advanced motion control features, the IC697CPU711 is more suited for applications requiring extensive logic processing and data handling. In contrast to the GE IC200CPU005, which is designed for simpler tasks, the IC697CPU711 is built to handle more complex automation challenges, making it a more versatile choice for engineers seeking a high-performance PLC.

Related Models:

The GE IC697CPU711 complements a wide range of other GE automation products, enhancing its functionality and adaptability. Some of these related models include:

1. GE SR750 – Known for its motion control capabilities.

2. GE IC697MDL740 – A versatile I/O module that pairs well with the IC697CPU711.

3. GE IS200DSFCG1AEB – A digital signal processing controller for specialized applications.

4. GE IC660BBA020 – A baseboard that supports various GE modules.

5. GE DS200DDTBG2A – A digital input terminal board compatible with the IC697 series.

6. GE IS200DSPXH2DBD – A dedicated signal processing module.

7. GE IC693APU301 – An advanced processing unit designed for complex applications.

8. GE IS200VTURH1BAC – A versatile controller

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.