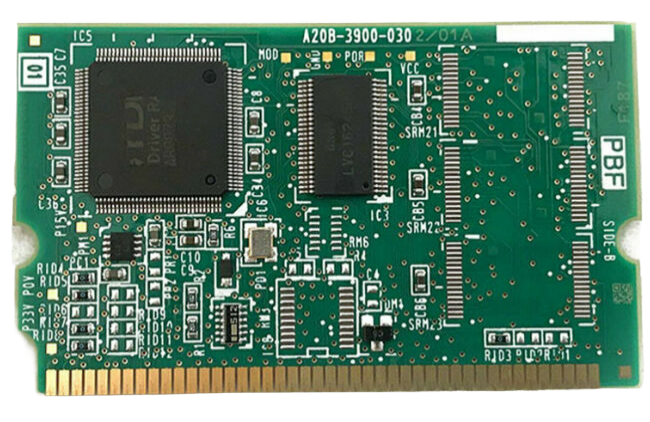

GE IC695PSD040F High-Efficiency Power Supply for Industrial Control Systems

Introducing the GE IC695PSD040F, a pivotal component in the world of industrial automation, engineered to elevate your operational capabilities. This high-performance product is part of GE’s extensive line of automation solutions, designed to streamline processes and improve efficiency across various industries. With its advanced features, the GE IC695PSD040F stands out as a reliable choice for automation professionals seeking precision and reliability in their systems.

Key Technical Features

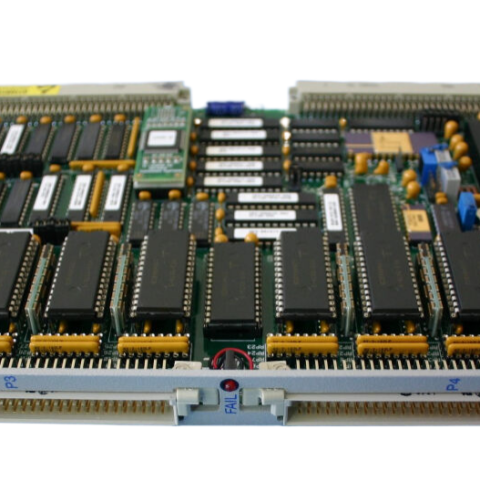

The GE IC695PSD040F boasts a powerful suite of technical features that make it an essential tool for modern industrial applications. This model offers 40 digital inputs and 40 digital outputs, providing ample connectivity options for a wide range of devices. Its robust processing power ensures quick data handling and real-time decision-making, crucial for maintaining optimal operation in complex environments. The IC695PSD040F also supports a variety of communication protocols, allowing seamless integration with existing systems and enhancing interoperability across different GE automation products.

Moreover, the IC695PSD040F includes built-in diagnostics and monitoring capabilities, enabling proactive maintenance and minimizing downtime. This feature allows operators to identify potential issues before they escalate, ensuring that systems run smoothly. With a compact design, this model is ideal for environments where space is at a premium without compromising performance.

Usage Scenarios

The versatility of the GE IC695PSD040F makes it suitable for a variety of applications. It is particularly effective in manufacturing environments, where it can manage assembly lines, robotic systems, and process control applications. Its ability to handle multiple input and output operations simultaneously allows for efficient coordination of complex machinery, making it an invaluable asset in production facilities.

In the energy sector, the IC695PSD040F can be deployed for monitoring and controlling power generation systems, ensuring that energy output is optimized. Additionally, its robust design makes it ideal for harsh environments, including oil and gas operations, where reliability is paramount. Whether used in automotive manufacturing, food processing, or renewable energy applications, the GE IC695PSD040F is engineered to meet the demands of various industrial challenges.

Comparison with Other Models

When compared to other models in the GE lineup, such as the GE SR750 or GE IC697MDL740, the IC695PSD040F offers a balance of advanced features and user-friendly operation. While the SR750 provides extensive data logging capabilities, the IC695PSD040F focuses on real-time processing and control, making it a better choice for applications requiring immediate response to changes in the environment. In contrast, models like the GE IS200DSPXH2DBD may cater to more specialized needs, but the IC695PSD040F offers broader compatibility and versatility, making it ideal for diverse operational requirements.

Additionally, when compared to the GE IC693APU301, which focuses primarily on analog inputs, the IC695PSD040F excels in managing digital signals, providing a more comprehensive solution for automated systems that rely on digital control.

Related Models

For those exploring options within the GE automation products portfolio, consider these related models: GE

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE IC695PSD040F boasts a powerful suite of technical features that make it an essential tool for modern industrial applications. This model offers 40 digital inputs and 40 digital outputs, providing ample connectivity options for a wide range of devices. Its robust processing power ensures quick data handling and real-time decision-making, crucial for maintaining optimal operation in complex environments. The IC695PSD040F also supports a variety of communication protocols, allowing seamless integration with existing systems and enhancing interoperability across different GE automation products.

Moreover, the IC695PSD040F includes built-in diagnostics and monitoring capabilities, enabling proactive maintenance and minimizing downtime. This feature allows operators to identify potential issues before they escalate, ensuring that systems run smoothly. With a compact design, this model is ideal for environments where space is at a premium without compromising performance.

Usage Scenarios

The versatility of the GE IC695PSD040F makes it suitable for a variety of applications. It is particularly effective in manufacturing environments, where it can manage assembly lines, robotic systems, and process control applications. Its ability to handle multiple input and output operations simultaneously allows for efficient coordination of complex machinery, making it an invaluable asset in production facilities.

In the energy sector, the IC695PSD040F can be deployed for monitoring and controlling power generation systems, ensuring that energy output is optimized. Additionally, its robust design makes it ideal for harsh environments, including oil and gas operations, where reliability is paramount. Whether used in automotive manufacturing, food processing, or renewable energy applications, the GE IC695PSD040F is engineered to meet the demands of various industrial challenges.

Comparison with Other Models

When compared to other models in the GE lineup, such as the GE SR750 or GE IC697MDL740, the IC695PSD040F offers a balance of advanced features and user-friendly operation. While the SR750 provides extensive data logging capabilities, the IC695PSD040F focuses on real-time processing and control, making it a better choice for applications requiring immediate response to changes in the environment. In contrast, models like the GE IS200DSPXH2DBD may cater to more specialized needs, but the IC695PSD040F offers broader compatibility and versatility, making it ideal for diverse operational requirements.

Additionally, when compared to the GE IC693APU301, which focuses primarily on analog inputs, the IC695PSD040F excels in managing digital signals, providing a more comprehensive solution for automated systems that rely on digital control.

Related Models

For those exploring options within the GE automation products portfolio, consider these related models: GE

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.