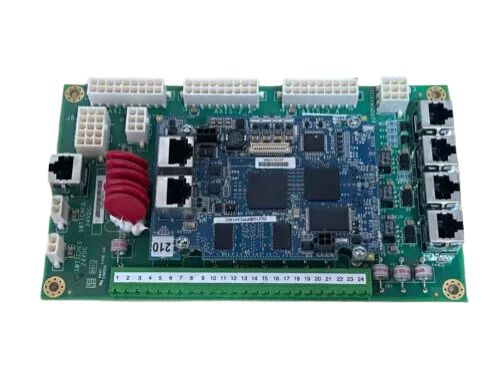

GE IC695PMM335 PACMotion Multi-Axis Motion Controller

Introducing the GE IC695PMM335, a premier offering in GE's robust lineup of automation products. This model stands out for its exceptional capabilities and reliability, making it an ideal choice for industrial applications that require precise control and monitoring.

The GE IC695PMM335 is equipped with a powerful processor that enhances processing capabilities, allowing for faster data handling and improved overall system performance. Key technical features include high-speed communication ports, multiple I/O options, and extensive memory capacity. This model supports both Ethernet and serial communications, enabling seamless integration with other GE automation products and third-party systems. Furthermore, its modular design allows for easy expansion to accommodate future growth and evolving operational needs.

One of the standout features of the GE IC695PMM335 is its versatility in usage scenarios. Whether you are managing complex manufacturing processes, monitoring critical infrastructure, or overseeing energy distribution systems, this model is engineered to meet the demands of various industrial applications. Its ability to handle real-time data processing and control makes it a suitable solution for industries such as oil and gas, water treatment, and manufacturing. Additionally, the GE IC695PMM335 supports advanced analytics and predictive maintenance, providing operators with valuable insights to enhance operational efficiency and reduce downtime.

When comparing the GE IC695PMM335 to other models in the GE family, such as the GE IC695CPE310-ABAH and GE IC693APU301, it becomes evident that the IC695PMM335 offers superior processing speed and enhanced connectivity options. While the IC695CPE310-ABAH provides robust performance for standard applications, the IC695PMM335 is specifically designed for demanding environments where rapid data processing is critical. In contrast, models like the GE IC697MDL740 and GE IC660BBA020 are focused on discrete I/O and analog control, making them ideal for specific tasks, but they may not match the versatility and high-speed capabilities of the IC695PMM335.

The GE IC695PMM335 also compares favorably with older models such as the GE IS200DSPXH2DBD and GE IS200VTURH1BAC, which, while reliable, may lack the advanced features and processing power that the IC695PMM335 brings to the table. For users still operating legacy systems, the transition to the IC695PMM335 can provide significant performance improvements and future-proofing for ongoing industrial automation needs.

In addition to its advanced features and capabilities, the GE IC695PMM335 is designed with user-friendly interfaces and robust software support. GE's comprehensive programming tools and intuitive design software make it easy for engineers and technicians to implement and modify control strategies without extensive retraining. This ease of use helps streamline operations and reduce time to deployment.

Related models that complement the GE IC695PMM335 include the GE IS220PPDAH1A, GE IC200CPU005, GE DS200DDTBG2A, and GE IC200UAL005. Each of these models offers specific

The above parameters are for reference only. Please contact our technical team for precise selection.

The GE IC695PMM335 is equipped with a powerful processor that enhances processing capabilities, allowing for faster data handling and improved overall system performance. Key technical features include high-speed communication ports, multiple I/O options, and extensive memory capacity. This model supports both Ethernet and serial communications, enabling seamless integration with other GE automation products and third-party systems. Furthermore, its modular design allows for easy expansion to accommodate future growth and evolving operational needs.

One of the standout features of the GE IC695PMM335 is its versatility in usage scenarios. Whether you are managing complex manufacturing processes, monitoring critical infrastructure, or overseeing energy distribution systems, this model is engineered to meet the demands of various industrial applications. Its ability to handle real-time data processing and control makes it a suitable solution for industries such as oil and gas, water treatment, and manufacturing. Additionally, the GE IC695PMM335 supports advanced analytics and predictive maintenance, providing operators with valuable insights to enhance operational efficiency and reduce downtime.

When comparing the GE IC695PMM335 to other models in the GE family, such as the GE IC695CPE310-ABAH and GE IC693APU301, it becomes evident that the IC695PMM335 offers superior processing speed and enhanced connectivity options. While the IC695CPE310-ABAH provides robust performance for standard applications, the IC695PMM335 is specifically designed for demanding environments where rapid data processing is critical. In contrast, models like the GE IC697MDL740 and GE IC660BBA020 are focused on discrete I/O and analog control, making them ideal for specific tasks, but they may not match the versatility and high-speed capabilities of the IC695PMM335.

The GE IC695PMM335 also compares favorably with older models such as the GE IS200DSPXH2DBD and GE IS200VTURH1BAC, which, while reliable, may lack the advanced features and processing power that the IC695PMM335 brings to the table. For users still operating legacy systems, the transition to the IC695PMM335 can provide significant performance improvements and future-proofing for ongoing industrial automation needs.

In addition to its advanced features and capabilities, the GE IC695PMM335 is designed with user-friendly interfaces and robust software support. GE's comprehensive programming tools and intuitive design software make it easy for engineers and technicians to implement and modify control strategies without extensive retraining. This ease of use helps streamline operations and reduce time to deployment.

Related models that complement the GE IC695PMM335 include the GE IS220PPDAH1A, GE IC200CPU005, GE DS200DDTBG2A, and GE IC200UAL005. Each of these models offers specific

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.