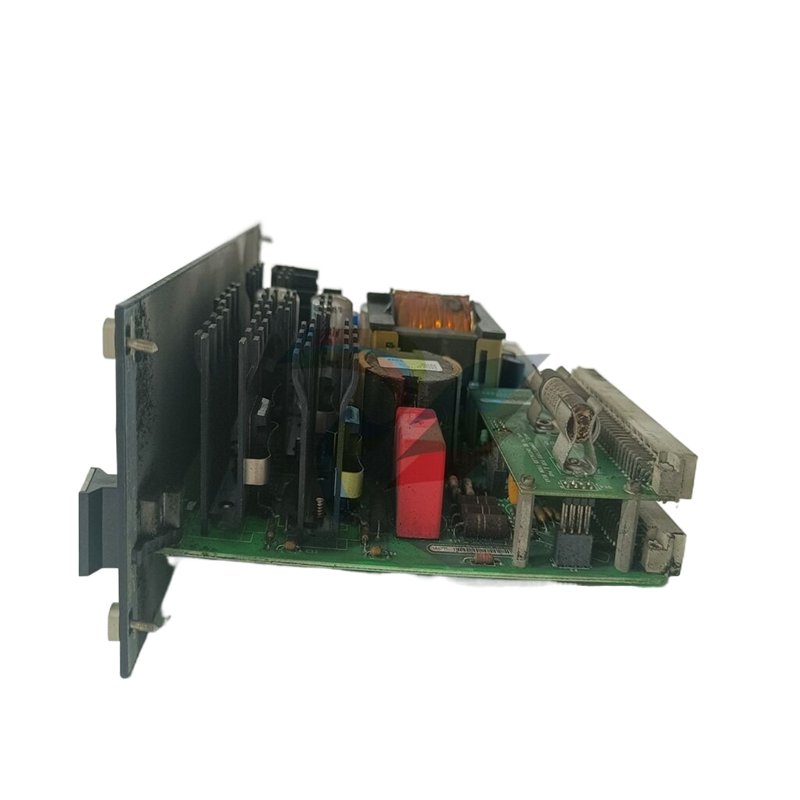

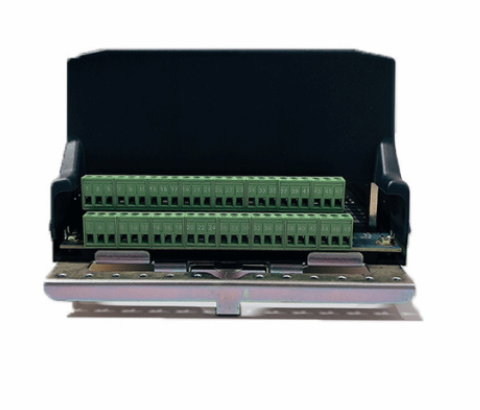

GE IC660ELB921M High-Performance PLC Module

Introducing the GE IC660ELB921M, a cutting-edge addition to the GE automation products lineup, designed to enhance operational efficiency and provide reliable performance across various industrial applications. This exceptional model is engineered to meet the demands of modern automation systems with a focus on versatility, advanced technology, and seamless integration into existing infrastructures.

Key Technical Features

The GE IC660ELB921M is equipped with a robust set of features that set it apart in the realm of industrial automation. It boasts a high-density design, allowing for efficient space utilization in control panels and machinery setups. With a wide range of input and output options, this model supports various sensors and actuators, making it adaptable to diverse environmental conditions and operational requirements. The unit provides exceptional processing speed, ensuring rapid data handling and real-time responses critical in time-sensitive applications. Moreover, it is designed with enhanced communication capabilities, enabling smooth integration with other GE automation products and third-party devices, facilitating a more cohesive automation ecosystem.

Usage Scenarios

The GE IC660ELB921M is ideally suited for a variety of industrial environments, including manufacturing, oil and gas, water treatment, and transportation. In manufacturing, it can manage complex assembly lines, ensuring that production processes are streamlined and efficient. In the oil and gas sector, this model can monitor and control various parameters, contributing to safer and more effective operations. For water treatment facilities, the GE IC660ELB921M can oversee vital processes like filtration and chemical dosing, enhancing water quality while maintaining strict compliance with environmental regulations. Its versatility makes it an excellent choice for systems requiring precise control and monitoring across various stages of production and distribution.

Comparison with Other Models

When compared to other models within the GE automation products family, such as the GE IS200TBCIH1BBC and the GE IC697MDL250, the GE IC660ELB921M stands out for its high-density I/O capabilities and superior processing speed. While the IS200TBCIH1BBC excels in temperature control applications, the IC660ELB921M is better suited for applications that require faster data throughput and greater flexibility in I/O configurations. Additionally, the IC697MDL250 offers reliable performance for basic control tasks, but it lacks the advanced communication features found in the IC660ELB921M, making the latter a more future-proof choice for businesses looking to expand their automation capabilities.

Reference to Related Models

For those exploring options within the GE automation ecosystem, the GE IC660ELB921M can be compared to several related models, including the GE IS220PPROS1B, known for its high-performance processing; the GE IS215UCVEH2AB, which offers exceptional user-friendly interfaces; and the GE IC670MDL740J, recognized for its rugged design suitable for harsh environments. Other noteworthy mentions include the GE IS200DSPXH1DBC for digital signal processing applications, the GE IC693CPU374 for versatile CPU functionality, and the GE DS200SDCCG1AGD, which excels in distributed control systems. The GE IS230SNIDH1A and the GE IC670CHS001E also provide excellent alternatives, depending on the specific needs and existing infrastructure of your automation setup.

In conclusion, the GE IC660ELB921M represents a pinnacle of innovation in the automation sector, offering unmatched reliability, performance, and versatility. Its advanced features and adaptability make it a compelling choice for businesses seeking to optimize their operations. Whether integrating with existing systems or deploying a new automation solution, the GE IC660ELB921M is a powerful ally in driving efficiency and productivity in today’s fast-paced industrial landscape. Explore the future of automation with the GE IC660ELB921M and discover how it can transform your operational capabilities today.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE IC660ELB921M is equipped with a robust set of features that set it apart in the realm of industrial automation. It boasts a high-density design, allowing for efficient space utilization in control panels and machinery setups. With a wide range of input and output options, this model supports various sensors and actuators, making it adaptable to diverse environmental conditions and operational requirements. The unit provides exceptional processing speed, ensuring rapid data handling and real-time responses critical in time-sensitive applications. Moreover, it is designed with enhanced communication capabilities, enabling smooth integration with other GE automation products and third-party devices, facilitating a more cohesive automation ecosystem.

Usage Scenarios

The GE IC660ELB921M is ideally suited for a variety of industrial environments, including manufacturing, oil and gas, water treatment, and transportation. In manufacturing, it can manage complex assembly lines, ensuring that production processes are streamlined and efficient. In the oil and gas sector, this model can monitor and control various parameters, contributing to safer and more effective operations. For water treatment facilities, the GE IC660ELB921M can oversee vital processes like filtration and chemical dosing, enhancing water quality while maintaining strict compliance with environmental regulations. Its versatility makes it an excellent choice for systems requiring precise control and monitoring across various stages of production and distribution.

Comparison with Other Models

When compared to other models within the GE automation products family, such as the GE IS200TBCIH1BBC and the GE IC697MDL250, the GE IC660ELB921M stands out for its high-density I/O capabilities and superior processing speed. While the IS200TBCIH1BBC excels in temperature control applications, the IC660ELB921M is better suited for applications that require faster data throughput and greater flexibility in I/O configurations. Additionally, the IC697MDL250 offers reliable performance for basic control tasks, but it lacks the advanced communication features found in the IC660ELB921M, making the latter a more future-proof choice for businesses looking to expand their automation capabilities.

Reference to Related Models

For those exploring options within the GE automation ecosystem, the GE IC660ELB921M can be compared to several related models, including the GE IS220PPROS1B, known for its high-performance processing; the GE IS215UCVEH2AB, which offers exceptional user-friendly interfaces; and the GE IC670MDL740J, recognized for its rugged design suitable for harsh environments. Other noteworthy mentions include the GE IS200DSPXH1DBC for digital signal processing applications, the GE IC693CPU374 for versatile CPU functionality, and the GE DS200SDCCG1AGD, which excels in distributed control systems. The GE IS230SNIDH1A and the GE IC670CHS001E also provide excellent alternatives, depending on the specific needs and existing infrastructure of your automation setup.

In conclusion, the GE IC660ELB921M represents a pinnacle of innovation in the automation sector, offering unmatched reliability, performance, and versatility. Its advanced features and adaptability make it a compelling choice for businesses seeking to optimize their operations. Whether integrating with existing systems or deploying a new automation solution, the GE IC660ELB921M is a powerful ally in driving efficiency and productivity in today’s fast-paced industrial landscape. Explore the future of automation with the GE IC660ELB921M and discover how it can transform your operational capabilities today.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.