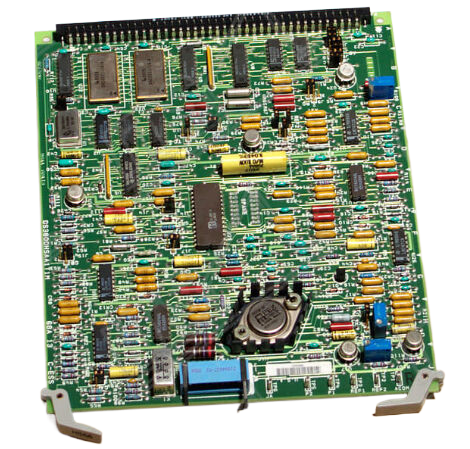

GE Fanuc WHEDCO TGT-000A-4-0-CA Programmable Logic Controller Module

Introducing the GE Fanuc: A Leader in Industrial Automation Solutions

The GE Fanuc model stands as a hallmark of reliability and innovation in the realm of industrial automation products. Designed to meet the rigorous demands of various industries, GE Fanuc systems are known for their robust performance, extensive functionality, and seamless integration capabilities.

Key Technical Features

The GE Fanuc model boasts a range of advanced technical features that enhance its operational efficiency. With high processing power and memory capacity, it can handle complex automation tasks with ease. The system supports multiple communication protocols, making it compatible with a wide array of devices and networks. Its modular architecture allows for scalability, enabling users to expand their systems in response to evolving operational needs. Additionally, the GE Fanuc comes equipped with state-of-the-art diagnostics and monitoring tools, ensuring real-time performance tracking and maintenance alerts.

Another standout feature is the model's user-friendly interface, which simplifies programming and configuration. This ease of use is complemented by comprehensive support for both hardware and software, making it an ideal choice for both seasoned professionals and those new to the field of industrial automation.

Usage Scenarios

The versatility of the GE Fanuc model makes it suitable for a multitude of application scenarios. In manufacturing environments, it can streamline production processes, optimize resource allocation, and enhance overall operational efficiency. In the energy sector, it plays a critical role in monitoring and controlling various systems, ensuring the reliability and safety of plant operations.

Moreover, the GE Fanuc model is frequently utilized in the transportation industry, where it aids in traffic management systems, signaling, and control applications. Its robust architecture is also well-suited for the oil and gas sector, facilitating real-time data acquisition and process control in remote locations.

Comparison with Other Models

When compared to other models within the GE brand, such as the GE SR750 and GE IC697MDL740, the GE Fanuc stands out for its superior processing speed and enhanced memory capabilities. While the GE IS200DSFCG1AEB is known for its specific applications in turbine control, the GE Fanuc offers a broader range of functionalities that cater to diverse automation needs.

In contrast to the GE IC693APU301, which is designed primarily for communication processing, the GE Fanuc combines this capability with extensive control features, making it a more comprehensive solution for industrial automation. Additionally, the GE DS200DDTBG2A is tailored for specific control tasks, whereas the GE Fanuc serves as a versatile platform that can adapt to various operational requirements.

Reference to Related Models

For those considering the GE Fanuc, it's worth noting its compatibility with several related models that enhance its functionality and expand its application range. Models such as the GE IS200DSPXH2DBD, GE IC660BBA020, and GE IS200JPDMG1ADC complement the GE Fanuc in specific industrial tasks. Other noteworthy models include the GE IC200CPU005, GE IC695CPE310-ABAH, and GE IS200

The above parameters are for reference only. Please contact our technical team for precise selection.

The GE Fanuc model stands as a hallmark of reliability and innovation in the realm of industrial automation products. Designed to meet the rigorous demands of various industries, GE Fanuc systems are known for their robust performance, extensive functionality, and seamless integration capabilities.

Key Technical Features

The GE Fanuc model boasts a range of advanced technical features that enhance its operational efficiency. With high processing power and memory capacity, it can handle complex automation tasks with ease. The system supports multiple communication protocols, making it compatible with a wide array of devices and networks. Its modular architecture allows for scalability, enabling users to expand their systems in response to evolving operational needs. Additionally, the GE Fanuc comes equipped with state-of-the-art diagnostics and monitoring tools, ensuring real-time performance tracking and maintenance alerts.

Another standout feature is the model's user-friendly interface, which simplifies programming and configuration. This ease of use is complemented by comprehensive support for both hardware and software, making it an ideal choice for both seasoned professionals and those new to the field of industrial automation.

Usage Scenarios

The versatility of the GE Fanuc model makes it suitable for a multitude of application scenarios. In manufacturing environments, it can streamline production processes, optimize resource allocation, and enhance overall operational efficiency. In the energy sector, it plays a critical role in monitoring and controlling various systems, ensuring the reliability and safety of plant operations.

Moreover, the GE Fanuc model is frequently utilized in the transportation industry, where it aids in traffic management systems, signaling, and control applications. Its robust architecture is also well-suited for the oil and gas sector, facilitating real-time data acquisition and process control in remote locations.

Comparison with Other Models

When compared to other models within the GE brand, such as the GE SR750 and GE IC697MDL740, the GE Fanuc stands out for its superior processing speed and enhanced memory capabilities. While the GE IS200DSFCG1AEB is known for its specific applications in turbine control, the GE Fanuc offers a broader range of functionalities that cater to diverse automation needs.

In contrast to the GE IC693APU301, which is designed primarily for communication processing, the GE Fanuc combines this capability with extensive control features, making it a more comprehensive solution for industrial automation. Additionally, the GE DS200DDTBG2A is tailored for specific control tasks, whereas the GE Fanuc serves as a versatile platform that can adapt to various operational requirements.

Reference to Related Models

For those considering the GE Fanuc, it's worth noting its compatibility with several related models that enhance its functionality and expand its application range. Models such as the GE IS200DSPXH2DBD, GE IC660BBA020, and GE IS200JPDMG1ADC complement the GE Fanuc in specific industrial tasks. Other noteworthy models include the GE IC200CPU005, GE IC695CPE310-ABAH, and GE IS200

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.