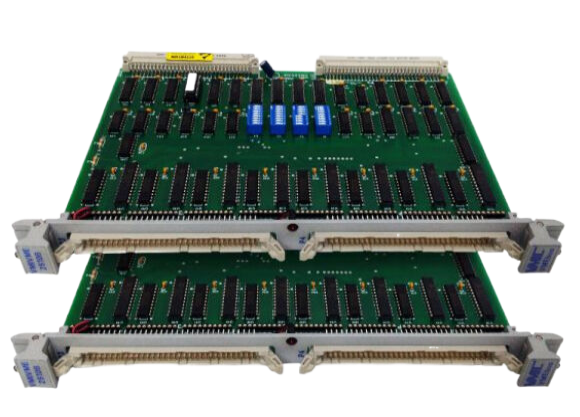

GE Fanuc VMIVME-7750-746000 Industrial Control Module

Introducing the GE Fanuc: A Pillar of Reliability and Innovation in Automation

In the realm of industrial automation, few brands command the respect and reliability that GE Fanuc does. Known for its innovative solutions and robust performance, the GE Fanuc series is designed to meet the evolving demands of modern industries. With its cutting-edge technology, the GE Fanuc stands out as a versatile automation product that can enhance productivity, efficiency, and precision in various applications.

Key Technical Features

The GE Fanuc systems are engineered with a suite of advanced features that make them indispensable in today’s manufacturing landscape. These include:

1. **High Processing Power**: Equipped with powerful processors, the GE Fanuc ensures rapid data processing and execution of complex tasks, making it suitable for high-demand environments.

2. **Modular Design**: The modular architecture allows for flexible configurations, enabling users to customize their setups based on specific operational needs. This adaptability is crucial for industries that undergo frequent changes in production requirements.

3. **Robust Communication Protocols**: With support for multiple communication protocols, including Ethernet and serial options, the GE Fanuc facilitates seamless integration with existing systems and enhances connectivity across devices.

4. **Scalability**: The GE Fanuc systems are designed to grow with your business. Users can easily expand their systems by adding new modules or components, ensuring long-term investment viability.

5. **Enhanced Diagnostics**: Built-in diagnostic features provide real-time monitoring and troubleshooting capabilities, reducing downtime and improving operational efficiency.

Usage Scenarios

The versatility of the GE Fanuc makes it suitable for a wide range of applications across various industries. For instance, in manufacturing environments, it can control assembly lines, monitor machinery performance, and manage inventory systems. In the energy sector, GE Fanuc systems are utilized for monitoring and controlling power generation equipment, ensuring optimal performance and safety. Additionally, the GE Fanuc solution is ideal for process automation in chemical plants, food and beverage production, and material handling systems, where precision and reliability are paramount.

Comparison with Other Models

When comparing the GE Fanuc with other models within the GE portfolio, such as the GE SR750 or the GE IC697MDL740, the advantages become evident. The SR750 offers advanced processing capabilities, making it suitable for data-intensive applications, while the IC697MDL740 specializes in discrete input/output control. However, the GE Fanuc combines these strengths, providing a comprehensive solution that excels in both data handling and control tasks.

In contrast to models like the GE IS200DSFCG1AEB or the GE IS200DSPXH2DBD, which focus on specific functionalities, the GE Fanuc serves as a more holistic solution, enabling users to tackle multiple automation challenges with a single system. This makes it an ideal choice for organizations looking to streamline their automation processes while maintaining high standards of performance.

Related Models

The GE Fanuc is part of a larger family of robust automation products, including:

1. GE

The above parameters are for reference only. Please contact our technical team for precise selection.

In the realm of industrial automation, few brands command the respect and reliability that GE Fanuc does. Known for its innovative solutions and robust performance, the GE Fanuc series is designed to meet the evolving demands of modern industries. With its cutting-edge technology, the GE Fanuc stands out as a versatile automation product that can enhance productivity, efficiency, and precision in various applications.

Key Technical Features

The GE Fanuc systems are engineered with a suite of advanced features that make them indispensable in today’s manufacturing landscape. These include:

1. **High Processing Power**: Equipped with powerful processors, the GE Fanuc ensures rapid data processing and execution of complex tasks, making it suitable for high-demand environments.

2. **Modular Design**: The modular architecture allows for flexible configurations, enabling users to customize their setups based on specific operational needs. This adaptability is crucial for industries that undergo frequent changes in production requirements.

3. **Robust Communication Protocols**: With support for multiple communication protocols, including Ethernet and serial options, the GE Fanuc facilitates seamless integration with existing systems and enhances connectivity across devices.

4. **Scalability**: The GE Fanuc systems are designed to grow with your business. Users can easily expand their systems by adding new modules or components, ensuring long-term investment viability.

5. **Enhanced Diagnostics**: Built-in diagnostic features provide real-time monitoring and troubleshooting capabilities, reducing downtime and improving operational efficiency.

Usage Scenarios

The versatility of the GE Fanuc makes it suitable for a wide range of applications across various industries. For instance, in manufacturing environments, it can control assembly lines, monitor machinery performance, and manage inventory systems. In the energy sector, GE Fanuc systems are utilized for monitoring and controlling power generation equipment, ensuring optimal performance and safety. Additionally, the GE Fanuc solution is ideal for process automation in chemical plants, food and beverage production, and material handling systems, where precision and reliability are paramount.

Comparison with Other Models

When comparing the GE Fanuc with other models within the GE portfolio, such as the GE SR750 or the GE IC697MDL740, the advantages become evident. The SR750 offers advanced processing capabilities, making it suitable for data-intensive applications, while the IC697MDL740 specializes in discrete input/output control. However, the GE Fanuc combines these strengths, providing a comprehensive solution that excels in both data handling and control tasks.

In contrast to models like the GE IS200DSFCG1AEB or the GE IS200DSPXH2DBD, which focus on specific functionalities, the GE Fanuc serves as a more holistic solution, enabling users to tackle multiple automation challenges with a single system. This makes it an ideal choice for organizations looking to streamline their automation processes while maintaining high standards of performance.

Related Models

The GE Fanuc is part of a larger family of robust automation products, including:

1. GE

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.