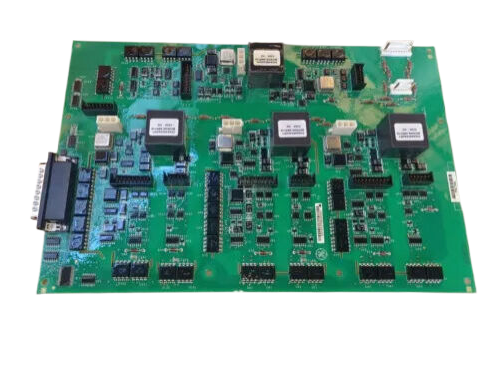

GE Fanuc LC694CHS398 | 5-slot Expansion Baseplate for Advanced Industrial Automation

Introducing the GE Fanuc, a cornerstone of GE’s commitment to delivering cutting-edge automation solutions designed to enhance efficiency and performance across various industrial applications. Renowned for its reliability and versatility, the GE Fanuc model stands out in a crowded marketplace, embodying the essence of GE automation products.

Key Technical Features:

The GE Fanuc is engineered with advanced technology to meet the demanding needs of modern industries. It features a robust architecture that supports a wide range of input and output modules, ensuring seamless integration with existing systems. The model is equipped with high-speed processing capabilities, enabling it to handle complex computations and real-time data analysis with ease.

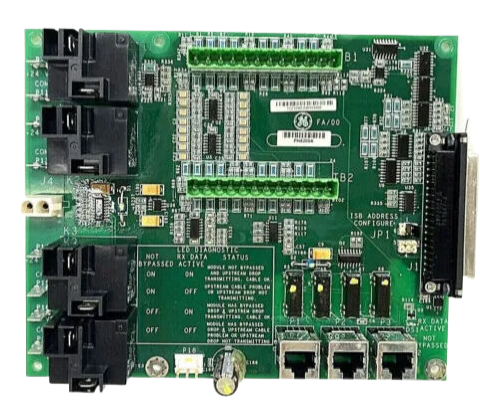

One of the standout features of the GE Fanuc is its extensive communication options. It supports multiple protocols, including Ethernet, which facilitates smooth communication between devices and enhances network flexibility. Additionally, the user-friendly programming environment allows engineers to develop custom applications quickly, reducing time-to-market for new products.

The GE Fanuc also includes built-in diagnostic tools that monitor system performance and preemptively address potential issues, ensuring maximum uptime. With its scalable design, the GE Fanuc can grow with your business, adapting to increased operational demands without requiring a complete system overhaul.

Usage Scenarios:

The versatility of the GE Fanuc makes it ideal for various sectors, including manufacturing, energy, transportation, and process control. In manufacturing, for instance, the GE Fanuc can be utilized for automating assembly lines, enhancing throughput, and ensuring product quality through precise control mechanisms.

In the energy sector, the GE Fanuc plays a crucial role in monitoring and controlling power generation and distribution systems, optimizing energy efficiency while ensuring compliance with regulatory standards. Its adaptability also makes it suitable for transportation applications, where it can manage traffic systems and improve logistics operations.

Moreover, the GE Fanuc is frequently employed in the process control sector, supervising chemical plants and food processing facilities to maintain product consistency and safety. Its ability to integrate with various sensors and devices allows it to gather real-time data, making it indispensable for modern automation needs.

Comparison with Other Models:

When comparing the GE Fanuc to other models within the GE family, such as the GE SR750 or the GE IS200DSPXH2DBD, the GE Fanuc offers enhanced communication features and a more extensive range of I/O options. While the GE SR750 is known for its specific applications in motor control, the GE Fanuc provides a broader scope of functionality suitable for diverse automation needs.

In contrast to the GE IC695CPE310-ABAH, which is designed for compact applications, the GE Fanuc excels in larger, more complex environments. The GE IS220PPDAH1A, while robust in its own right, lacks the flexibility and scalability that the GE Fanuc provides, making it less suitable for rapidly evolving industrial landscapes.

Related Models:

For those considering the GE Fanuc, several related models can further enhance your automation strategy. The GE IC697MDL740, GE IS200DSFCG1

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE Fanuc is engineered with advanced technology to meet the demanding needs of modern industries. It features a robust architecture that supports a wide range of input and output modules, ensuring seamless integration with existing systems. The model is equipped with high-speed processing capabilities, enabling it to handle complex computations and real-time data analysis with ease.

One of the standout features of the GE Fanuc is its extensive communication options. It supports multiple protocols, including Ethernet, which facilitates smooth communication between devices and enhances network flexibility. Additionally, the user-friendly programming environment allows engineers to develop custom applications quickly, reducing time-to-market for new products.

The GE Fanuc also includes built-in diagnostic tools that monitor system performance and preemptively address potential issues, ensuring maximum uptime. With its scalable design, the GE Fanuc can grow with your business, adapting to increased operational demands without requiring a complete system overhaul.

Usage Scenarios:

The versatility of the GE Fanuc makes it ideal for various sectors, including manufacturing, energy, transportation, and process control. In manufacturing, for instance, the GE Fanuc can be utilized for automating assembly lines, enhancing throughput, and ensuring product quality through precise control mechanisms.

In the energy sector, the GE Fanuc plays a crucial role in monitoring and controlling power generation and distribution systems, optimizing energy efficiency while ensuring compliance with regulatory standards. Its adaptability also makes it suitable for transportation applications, where it can manage traffic systems and improve logistics operations.

Moreover, the GE Fanuc is frequently employed in the process control sector, supervising chemical plants and food processing facilities to maintain product consistency and safety. Its ability to integrate with various sensors and devices allows it to gather real-time data, making it indispensable for modern automation needs.

Comparison with Other Models:

When comparing the GE Fanuc to other models within the GE family, such as the GE SR750 or the GE IS200DSPXH2DBD, the GE Fanuc offers enhanced communication features and a more extensive range of I/O options. While the GE SR750 is known for its specific applications in motor control, the GE Fanuc provides a broader scope of functionality suitable for diverse automation needs.

In contrast to the GE IC695CPE310-ABAH, which is designed for compact applications, the GE Fanuc excels in larger, more complex environments. The GE IS220PPDAH1A, while robust in its own right, lacks the flexibility and scalability that the GE Fanuc provides, making it less suitable for rapidly evolving industrial landscapes.

Related Models:

For those considering the GE Fanuc, several related models can further enhance your automation strategy. The GE IC697MDL740, GE IS200DSFCG1

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.