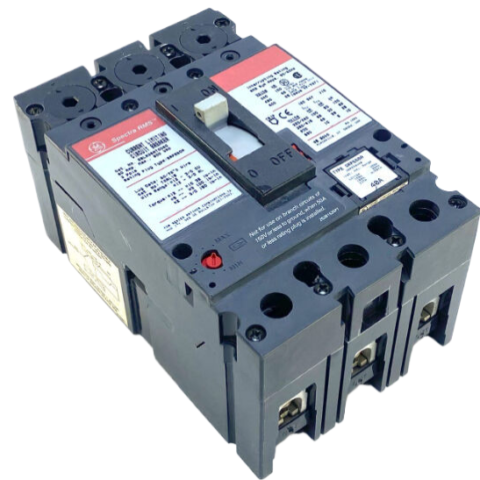

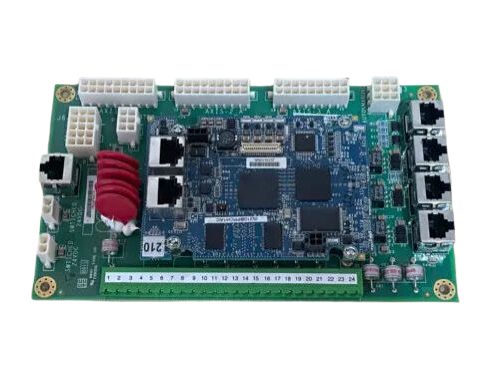

GE FANUC LC200PWR102 Industrial Power Supply Module

Introducing the GE FANUC, a premium solution in the realm of industrial automation. Designed with precision and reliability in mind, the GE FANUC model offers a robust portfolio of features that cater to a wide array of industrial applications. With its advanced technology and innovative design, this model stands as a benchmark for efficiency and performance in the automation sector.

Key technical features of the GE FANUC include a high-performance processing unit that ensures rapid data processing and seamless communication within your automation system. The model supports multiple communication protocols, enhancing interoperability with various devices and systems. Its modular design allows for easy scalability, enabling users to expand their systems without significant downtime. Additionally, the GE FANUC incorporates advanced diagnostic capabilities, providing real-time insights into system performance and facilitating proactive maintenance.

Usage scenarios for the GE FANUC are diverse and extensive. Whether in manufacturing, energy, or transportation, this model excels in environments that demand precision and reliability. For instance, in a manufacturing setting, the GE FANUC can be employed to control complex machinery, ensuring synchronized operations and high productivity levels. In energy sectors, it can optimize power distribution and monitor equipment health, reducing operational costs and minimizing downtime. Furthermore, in transportation systems, it plays a crucial role in managing traffic flow and ensuring safety through real-time monitoring and control.

When comparing the GE FANUC to other models within the GE family, such as the GE SR750 or GE IC697MDL740, it becomes clear that the GE FANUC offers unique advantages. While the SR750 is known for its high-speed capabilities, the GE FANUC excels in versatility, making it suitable for a broader range of applications. Similarly, the GE IC697MDL740 provides strong performance but may lack the comprehensive communication features that the GE FANUC offers, which is essential in today's interconnected industrial environments.

In addition to its competitive edge against models like the GE IS200DSFCG1AEB and GE IC660BBA020, the GE FANUC also stands out in its ability to integrate seamlessly with existing systems. For example, users of the GE IS200DSPXH2DBD will find that transitioning to the GE FANUC model is straightforward, thanks to its compatibility with a variety of GE automation products. Furthermore, the GE FANUC can be effectively paired with models such as the GE IS200VTURH1BAC and GE IC693APU301 to create a cohesive automation ecosystem that enhances overall operational efficiency.

For those looking to expand their automation capabilities, related models such as the GE IC200CPU005, GE IC3600A0AHIC, and GE IC695CPE310-ABAH are worthy considerations. Each of these models brings its unique strengths to the table, but the GE FANUC’s combination of advanced features and user-friendly interface sets it apart as a leader in the market. Additionally, models like the GE IS200EDFFH1ABA and GE IC695LRE001B can complement the GE FANUC in specific applications, providing a

The above parameters are for reference only. Please contact our technical team for precise selection.

Key technical features of the GE FANUC include a high-performance processing unit that ensures rapid data processing and seamless communication within your automation system. The model supports multiple communication protocols, enhancing interoperability with various devices and systems. Its modular design allows for easy scalability, enabling users to expand their systems without significant downtime. Additionally, the GE FANUC incorporates advanced diagnostic capabilities, providing real-time insights into system performance and facilitating proactive maintenance.

Usage scenarios for the GE FANUC are diverse and extensive. Whether in manufacturing, energy, or transportation, this model excels in environments that demand precision and reliability. For instance, in a manufacturing setting, the GE FANUC can be employed to control complex machinery, ensuring synchronized operations and high productivity levels. In energy sectors, it can optimize power distribution and monitor equipment health, reducing operational costs and minimizing downtime. Furthermore, in transportation systems, it plays a crucial role in managing traffic flow and ensuring safety through real-time monitoring and control.

When comparing the GE FANUC to other models within the GE family, such as the GE SR750 or GE IC697MDL740, it becomes clear that the GE FANUC offers unique advantages. While the SR750 is known for its high-speed capabilities, the GE FANUC excels in versatility, making it suitable for a broader range of applications. Similarly, the GE IC697MDL740 provides strong performance but may lack the comprehensive communication features that the GE FANUC offers, which is essential in today's interconnected industrial environments.

In addition to its competitive edge against models like the GE IS200DSFCG1AEB and GE IC660BBA020, the GE FANUC also stands out in its ability to integrate seamlessly with existing systems. For example, users of the GE IS200DSPXH2DBD will find that transitioning to the GE FANUC model is straightforward, thanks to its compatibility with a variety of GE automation products. Furthermore, the GE FANUC can be effectively paired with models such as the GE IS200VTURH1BAC and GE IC693APU301 to create a cohesive automation ecosystem that enhances overall operational efficiency.

For those looking to expand their automation capabilities, related models such as the GE IC200CPU005, GE IC3600A0AHIC, and GE IC695CPE310-ABAH are worthy considerations. Each of these models brings its unique strengths to the table, but the GE FANUC’s combination of advanced features and user-friendly interface sets it apart as a leader in the market. Additionally, models like the GE IS200EDFFH1ABA and GE IC695LRE001B can complement the GE FANUC in specific applications, providing a

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.