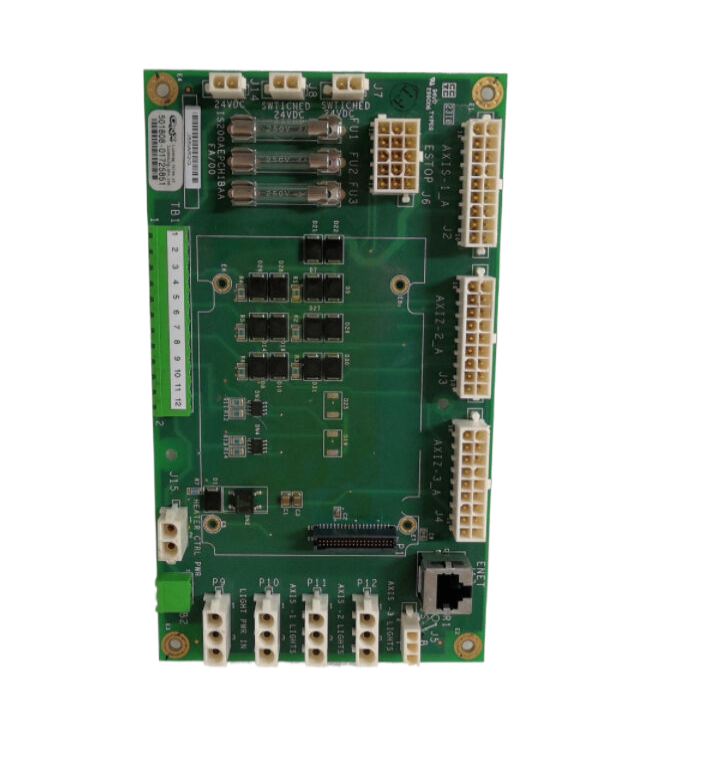

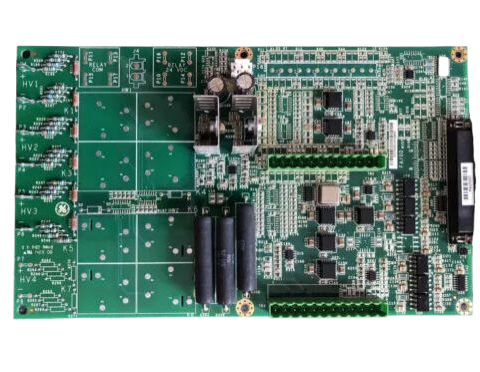

GE Fanuc IC698CRE030EE Advanced PLC Central Processing Unit

Introducing the GE Fanuc, a pinnacle in the realm of industrial automation, designed to enhance productivity and ensure reliability across a variety of applications. Known for its robust construction and advanced features, the GE Fanuc stands as a testament to GE's commitment to innovation in automation products that elevate operational efficiency.

Key Technical Features:

The GE Fanuc model is equipped with a powerful microprocessor that ensures high-speed processing and seamless integration with various automation systems. Its extensive input/output capabilities allow for versatile connectivity, making it suitable for complex control environments. The device supports multiple communication protocols, enabling integration with legacy systems as well as modern networking technologies. With a user-friendly interface and intuitive programming options, the GE Fanuc simplifies the setup and management of automation tasks. Additionally, its rugged design ensures durability in challenging industrial settings, providing a long lifespan with minimal maintenance requirements.

Usage Scenarios:

The GE Fanuc is ideal for a multitude of industrial applications, ranging from manufacturing processes to process control systems. In automotive assembly lines, it can manage robotic arms and conveyor systems, ensuring precise coordination and timing. In the food and beverage industry, it plays a crucial role in monitoring and controlling production lines, enhancing quality control and reducing waste. The GE Fanuc is also suitable for water treatment facilities where it can automate the monitoring of water quality and manage treatment processes. Its versatility extends to energy management systems, where it can optimize power distribution and monitor equipment health, contributing to overall operational efficiency.

Comparison with Other Models:

When compared to other models in the GE automation products lineup, such as the GE SR750 and GE IC695CPE310-ABAH, the GE Fanuc offers enhanced processing power and a broader range of connectivity options. While the SR750 is tailored for specific applications with a focus on ease of use, the GE Fanuc provides more expansive capabilities that cater to complex automation needs. In contrast to the GE IS200DSPXH2DBD, which excels in specific control applications, the GE Fanuc stands out for its adaptability across a wider range of industries, making it a more versatile choice for diverse operational demands.

Related Models:

The GE Fanuc is part of an extensive family of automation products, including the GE IC697MDL740, known for its high-density I/O modules, and the GE IS200DSFCG1AEB, which specializes in control system applications. Other notable models include the GE IC660BBA020, offering advanced communication capabilities, and the GE DS200DDTBG2A, which is designed for reliable data transmission. The GE IS200DSPXH2DBD is an excellent choice for digital signal processing tasks. For those requiring specific I/O configurations, the GE IC693APU301 and GE IC200CPU005 provide tailored solutions. Additionally, models like the GE IC695LRE001B and GE IS200EDFFH1ABA enhance the automation experience with their unique features. Lastly, the GE IC694PWR331 is an optimal choice

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE Fanuc model is equipped with a powerful microprocessor that ensures high-speed processing and seamless integration with various automation systems. Its extensive input/output capabilities allow for versatile connectivity, making it suitable for complex control environments. The device supports multiple communication protocols, enabling integration with legacy systems as well as modern networking technologies. With a user-friendly interface and intuitive programming options, the GE Fanuc simplifies the setup and management of automation tasks. Additionally, its rugged design ensures durability in challenging industrial settings, providing a long lifespan with minimal maintenance requirements.

Usage Scenarios:

The GE Fanuc is ideal for a multitude of industrial applications, ranging from manufacturing processes to process control systems. In automotive assembly lines, it can manage robotic arms and conveyor systems, ensuring precise coordination and timing. In the food and beverage industry, it plays a crucial role in monitoring and controlling production lines, enhancing quality control and reducing waste. The GE Fanuc is also suitable for water treatment facilities where it can automate the monitoring of water quality and manage treatment processes. Its versatility extends to energy management systems, where it can optimize power distribution and monitor equipment health, contributing to overall operational efficiency.

Comparison with Other Models:

When compared to other models in the GE automation products lineup, such as the GE SR750 and GE IC695CPE310-ABAH, the GE Fanuc offers enhanced processing power and a broader range of connectivity options. While the SR750 is tailored for specific applications with a focus on ease of use, the GE Fanuc provides more expansive capabilities that cater to complex automation needs. In contrast to the GE IS200DSPXH2DBD, which excels in specific control applications, the GE Fanuc stands out for its adaptability across a wider range of industries, making it a more versatile choice for diverse operational demands.

Related Models:

The GE Fanuc is part of an extensive family of automation products, including the GE IC697MDL740, known for its high-density I/O modules, and the GE IS200DSFCG1AEB, which specializes in control system applications. Other notable models include the GE IC660BBA020, offering advanced communication capabilities, and the GE DS200DDTBG2A, which is designed for reliable data transmission. The GE IS200DSPXH2DBD is an excellent choice for digital signal processing tasks. For those requiring specific I/O configurations, the GE IC693APU301 and GE IC200CPU005 provide tailored solutions. Additionally, models like the GE IC695LRE001B and GE IS200EDFFH1ABA enhance the automation experience with their unique features. Lastly, the GE IC694PWR331 is an optimal choice

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.