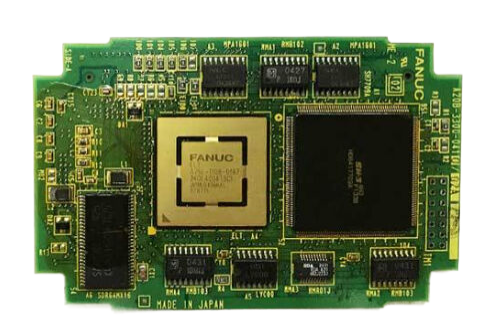

GE FANUC IC697MDL671 Interrupt Input Module Advanced Processing & Control

Introducing the GE FANUC: The Ultimate Solution for Industrial Automation

The GE FANUC series stands as a hallmark of reliability and efficiency in the realm of industrial automation. Renowned for its robust design and cutting-edge technology, the GE FANUC offers key technical features that set it apart from competitors. With high-performance processing capabilities, advanced communication options, and unparalleled scalability, the GE FANUC is tailored to meet the demanding needs of various industries, from manufacturing to energy management.

Key Technical Features

At the heart of the GE FANUC system lies its sophisticated processing unit, designed to deliver fast and accurate data processing. The model is equipped with a powerful CPU that supports multi-tasking and real-time operations, ensuring seamless performance under rigorous conditions. The GE FANUC also features extensive input/output (I/O) capabilities, allowing for easy integration with a wide range of sensors, actuators, and other automation components.

One of the standout features of the GE FANUC is its support for multiple communication protocols, including Ethernet/IP, Modbus, and Profibus. This versatility enables businesses to connect various devices and systems, facilitating smooth data exchange and enhanced operational efficiency. Additionally, the GE FANUC's user-friendly programming environment simplifies the development of complex automation solutions, empowering engineers to implement advanced control strategies with ease.

Usage Scenarios

The GE FANUC is an ideal choice for a diverse array of applications. In manufacturing, it can be employed for process control, machine automation, and quality assurance. Its ability to gather and analyze data in real-time enhances production efficiency and reduces downtime, making it invaluable for assembly lines and production facilities.

In the energy sector, the GE FANUC can monitor and control power generation and distribution systems, ensuring optimal performance and reliability. Its flexibility allows for deployment in renewable energy applications, such as wind and solar farms, where real-time data is crucial for maximizing output.

Moreover, the GE FANUC is also suitable for building automation systems, providing centralized control for lighting, HVAC, and security systems within commercial and industrial buildings. This versatility positions the GE FANUC as a cornerstone of modern automation strategies.

Comparison with Other Models

When comparing the GE FANUC to other models within the GE automation products lineup, such as the GE SR750 or GE IS200DSPXH2DBD, the FANUC stands out due to its superior processing speed and extensive networking capabilities. While models like the GE IC693APU301 excel in specific applications, the GE FANUC's all-around performance makes it a more versatile choice for organizations looking to implement comprehensive automation strategies.

Additionally, unlike the GE IS220PPDAH1A, which is more tailored for specific control applications, the GE FANUC is designed to adapt to a wide variety of operational needs. This adaptability, combined with its robust support for various protocols, makes it a preferred option for businesses seeking to future-proof their automation investments.

Related Models

The GE FANUC is part of a broader ecosystem of GE automation products, including the GE IC

The above parameters are for reference only. Please contact our technical team for precise selection.

The GE FANUC series stands as a hallmark of reliability and efficiency in the realm of industrial automation. Renowned for its robust design and cutting-edge technology, the GE FANUC offers key technical features that set it apart from competitors. With high-performance processing capabilities, advanced communication options, and unparalleled scalability, the GE FANUC is tailored to meet the demanding needs of various industries, from manufacturing to energy management.

Key Technical Features

At the heart of the GE FANUC system lies its sophisticated processing unit, designed to deliver fast and accurate data processing. The model is equipped with a powerful CPU that supports multi-tasking and real-time operations, ensuring seamless performance under rigorous conditions. The GE FANUC also features extensive input/output (I/O) capabilities, allowing for easy integration with a wide range of sensors, actuators, and other automation components.

One of the standout features of the GE FANUC is its support for multiple communication protocols, including Ethernet/IP, Modbus, and Profibus. This versatility enables businesses to connect various devices and systems, facilitating smooth data exchange and enhanced operational efficiency. Additionally, the GE FANUC's user-friendly programming environment simplifies the development of complex automation solutions, empowering engineers to implement advanced control strategies with ease.

Usage Scenarios

The GE FANUC is an ideal choice for a diverse array of applications. In manufacturing, it can be employed for process control, machine automation, and quality assurance. Its ability to gather and analyze data in real-time enhances production efficiency and reduces downtime, making it invaluable for assembly lines and production facilities.

In the energy sector, the GE FANUC can monitor and control power generation and distribution systems, ensuring optimal performance and reliability. Its flexibility allows for deployment in renewable energy applications, such as wind and solar farms, where real-time data is crucial for maximizing output.

Moreover, the GE FANUC is also suitable for building automation systems, providing centralized control for lighting, HVAC, and security systems within commercial and industrial buildings. This versatility positions the GE FANUC as a cornerstone of modern automation strategies.

Comparison with Other Models

When comparing the GE FANUC to other models within the GE automation products lineup, such as the GE SR750 or GE IS200DSPXH2DBD, the FANUC stands out due to its superior processing speed and extensive networking capabilities. While models like the GE IC693APU301 excel in specific applications, the GE FANUC's all-around performance makes it a more versatile choice for organizations looking to implement comprehensive automation strategies.

Additionally, unlike the GE IS220PPDAH1A, which is more tailored for specific control applications, the GE FANUC is designed to adapt to a wide variety of operational needs. This adaptability, combined with its robust support for various protocols, makes it a preferred option for businesses seeking to future-proof their automation investments.

Related Models

The GE FANUC is part of a broader ecosystem of GE automation products, including the GE IC

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.