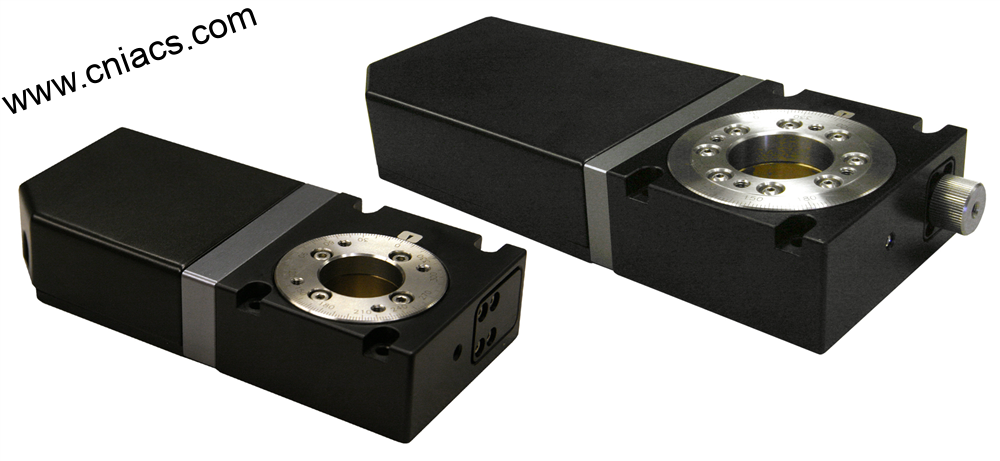

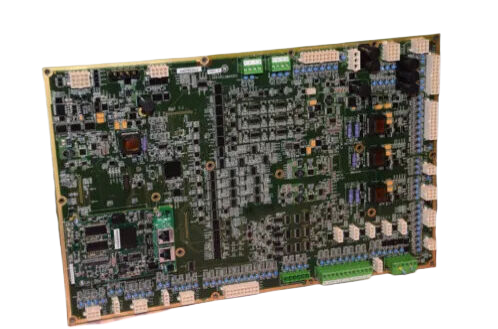

GE FANUC IC697MDL350 Discrete Output Module Efficient Control Solutions

Introducing the GE FANUC model, an essential component in the realm of industrial automation and control systems. Renowned for its reliability and performance, the GE FANUC series stands out among GE's extensive range of automation products, making it a preferred choice for industries looking to enhance operational efficiency.

Key Technical Features:

The GE FANUC model is engineered with cutting-edge technology that ensures seamless integration into existing systems. It boasts a robust processing capability, high-speed communication interfaces, and versatile I/O options, making it suitable for various applications. With its advanced diagnostic features, users can easily monitor system performance and swiftly identify issues, minimizing downtime. The user-friendly interface allows for straightforward programming and configuration, which is essential for operators of all skill levels. Additionally, the model supports various protocols, ensuring compatibility with other GE automation products and enhancing its functionality in diverse environments.

Usage Scenarios:

The versatility of the GE FANUC model makes it ideal for a wide range of applications across multiple industries. In manufacturing, it serves as a vital component in process control systems, providing real-time data processing and automation solutions. The model is also widely utilized in energy management systems, optimizing performance and reducing energy costs. Furthermore, the GE FANUC model is perfect for robotics applications, enabling precise control and coordination of robotic systems in assembly lines. Its reliability and performance make it suitable for use in harsh industrial environments, ensuring longevity and consistent operation.

Comparison with Other Models:

When compared to other models in the GE range, such as the GE IS200TBCIH1BBC and GE IS220PPROS1B, the GE FANUC model shines with its enhanced processing capabilities and superior communication options. While the IS200TBCIH1BBC is excellent for specific control tasks, it may lack the versatility and broader application scope of the GE FANUC. Similarly, the GE IS220PPROS1B is tailored for particular applications but does not match the comprehensive features offered by the GE FANUC model. In contrast, the GE FANUC model combines the best aspects of these models, providing a more holistic solution for industrial automation needs.

Related Models:

For those exploring the GE automation products line, several related models complement the GE FANUC. These include the GE IS215UCVEH2AB, known for its exceptional control capabilities, and the GE IC697MDL250, which offers reliable I/O connectivity. The GE PRG-MODEM facilitates communication between devices, while the GE IS200TPROH1BBB enhances process control. Additionally, the GE IC660ELB912G and GE IC660EBD020 models provide essential connectivity features, making them excellent companions to the GE FANUC. Other noteworthy mentions include the GE DS200SDCCG1AGD, GE IS200DSPXH1DBC, and GE IC670MDL640, all contributing to a robust and versatile automation ecosystem.

SEO Keywords:

In the vast landscape of industrial automation, GE FANUC stands out as a trusted name, synonymous with quality and innovation. As industries continue to evolve, the demand for reliable GE automation products grows, positioning the GE FANUC model as an essential tool for businesses aiming for excellence in their operations.

In conclusion, the GE FANUC model is a testament to GE's commitment to providing advanced automation solutions. With its key technical features, versatile usage scenarios, and superior performance compared to other models, it is an investment that promises to enhance productivity and efficiency across various industries. Whether you're in manufacturing, energy management, or robotics, the GE FANUC model is designed to meet your automation needs, ensuring you stay ahead in a competitive landscape. Embrace the future of industrial automation with the GE FANUC model, and experience the difference in operational excellence.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE FANUC model is engineered with cutting-edge technology that ensures seamless integration into existing systems. It boasts a robust processing capability, high-speed communication interfaces, and versatile I/O options, making it suitable for various applications. With its advanced diagnostic features, users can easily monitor system performance and swiftly identify issues, minimizing downtime. The user-friendly interface allows for straightforward programming and configuration, which is essential for operators of all skill levels. Additionally, the model supports various protocols, ensuring compatibility with other GE automation products and enhancing its functionality in diverse environments.

Usage Scenarios:

The versatility of the GE FANUC model makes it ideal for a wide range of applications across multiple industries. In manufacturing, it serves as a vital component in process control systems, providing real-time data processing and automation solutions. The model is also widely utilized in energy management systems, optimizing performance and reducing energy costs. Furthermore, the GE FANUC model is perfect for robotics applications, enabling precise control and coordination of robotic systems in assembly lines. Its reliability and performance make it suitable for use in harsh industrial environments, ensuring longevity and consistent operation.

Comparison with Other Models:

When compared to other models in the GE range, such as the GE IS200TBCIH1BBC and GE IS220PPROS1B, the GE FANUC model shines with its enhanced processing capabilities and superior communication options. While the IS200TBCIH1BBC is excellent for specific control tasks, it may lack the versatility and broader application scope of the GE FANUC. Similarly, the GE IS220PPROS1B is tailored for particular applications but does not match the comprehensive features offered by the GE FANUC model. In contrast, the GE FANUC model combines the best aspects of these models, providing a more holistic solution for industrial automation needs.

Related Models:

For those exploring the GE automation products line, several related models complement the GE FANUC. These include the GE IS215UCVEH2AB, known for its exceptional control capabilities, and the GE IC697MDL250, which offers reliable I/O connectivity. The GE PRG-MODEM facilitates communication between devices, while the GE IS200TPROH1BBB enhances process control. Additionally, the GE IC660ELB912G and GE IC660EBD020 models provide essential connectivity features, making them excellent companions to the GE FANUC. Other noteworthy mentions include the GE DS200SDCCG1AGD, GE IS200DSPXH1DBC, and GE IC670MDL640, all contributing to a robust and versatile automation ecosystem.

SEO Keywords:

In the vast landscape of industrial automation, GE FANUC stands out as a trusted name, synonymous with quality and innovation. As industries continue to evolve, the demand for reliable GE automation products grows, positioning the GE FANUC model as an essential tool for businesses aiming for excellence in their operations.

In conclusion, the GE FANUC model is a testament to GE's commitment to providing advanced automation solutions. With its key technical features, versatile usage scenarios, and superior performance compared to other models, it is an investment that promises to enhance productivity and efficiency across various industries. Whether you're in manufacturing, energy management, or robotics, the GE FANUC model is designed to meet your automation needs, ensuring you stay ahead in a competitive landscape. Embrace the future of industrial automation with the GE FANUC model, and experience the difference in operational excellence.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.