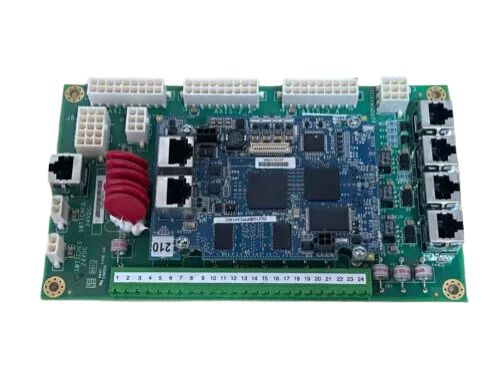

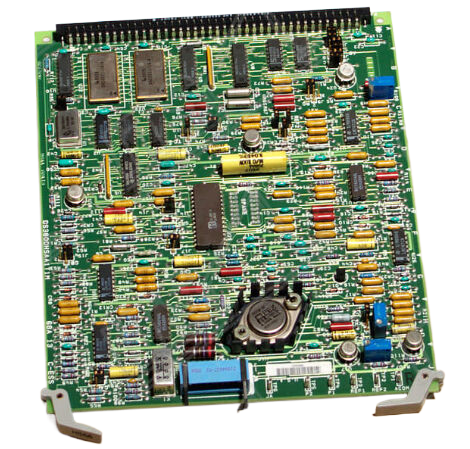

GE Fanuc IC697CPU731 High-Performance Central Processing Unit

Introducing the GE Fanuc: the pinnacle of reliability and performance in industrial automation. As a leader in the automation landscape, GE Fanuc products are engineered to deliver exceptional efficiency and precision across various applications. The GE Fanuc model stands out with its cutting-edge technology and robust feature set, making it an essential component for businesses seeking to optimize their operations.

Key Technical Features:

The GE Fanuc model is packed with features that enhance its functionality and adaptability. It boasts advanced processing capabilities, high-speed communication ports, and extensive I/O options, allowing seamless integration into existing systems. With its modular design, users can easily expand functionality by adding components that meet specific operational needs. The model supports a wide range of protocols, ensuring compatibility with various devices and systems in the GE automation products ecosystem. Furthermore, it is designed for high performance in harsh industrial environments, featuring robust protection against electrical interference and temperature fluctuations.

Usage Scenarios:

The versatility of the GE Fanuc makes it suitable for diverse applications across multiple industries. In manufacturing, it can control machinery and monitor production lines, ensuring optimal output and minimizing downtime. In the energy sector, the GE Fanuc is used for process automation, enabling real-time data collection and analysis to enhance decision-making. Additionally, in transportation and logistics, it plays a critical role in managing inventory systems and streamlining supply chains. Whether you are automating complex processes or managing simple tasks, the GE Fanuc provides the reliability and performance needed to drive operational success.

Comparison with Other Models:

When compared to other models in the GE lineup, such as the GE SR750 or GE IC697MDL740, the GE Fanuc distinguishes itself with its superior processing speed and flexibility. While the GE SR750 offers strong performance for high-demand applications, the GE Fanuc's modular approach provides users with more customization options. Similarly, while the GE IS200DSPXH2DBD is built for specific industrial applications, the GE Fanuc serves a broader range of automation needs, making it a more versatile choice for businesses looking to future-proof their operations.

Related Models:

For customers seeking alternatives or complementary products within the GE automation family, consider the following models: GE IS200EDFFH1ABA, GE IC693APU301, GE IC660BBA020, and GE IS200TRPGH1BDE. Each of these models offers unique specifications that cater to various automation needs. The GE IC200CPU005 and GE IC695CPE310-ABAH are excellent for those requiring integrated control solutions. Meanwhile, the GE DS200DDTBG2A and GE DS200SIOCG1A excel in I/O connectivity, making them ideal for applications that demand extensive data handling. Additionally, users may explore the GE IS220PPDAH1A and GE IC694PWR331 for more specialized functions.

In conclusion, the GE Fanuc is a powerful, flexible solution designed to meet the diverse needs of industries today. With its advanced technical features and broad range

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE Fanuc model is packed with features that enhance its functionality and adaptability. It boasts advanced processing capabilities, high-speed communication ports, and extensive I/O options, allowing seamless integration into existing systems. With its modular design, users can easily expand functionality by adding components that meet specific operational needs. The model supports a wide range of protocols, ensuring compatibility with various devices and systems in the GE automation products ecosystem. Furthermore, it is designed for high performance in harsh industrial environments, featuring robust protection against electrical interference and temperature fluctuations.

Usage Scenarios:

The versatility of the GE Fanuc makes it suitable for diverse applications across multiple industries. In manufacturing, it can control machinery and monitor production lines, ensuring optimal output and minimizing downtime. In the energy sector, the GE Fanuc is used for process automation, enabling real-time data collection and analysis to enhance decision-making. Additionally, in transportation and logistics, it plays a critical role in managing inventory systems and streamlining supply chains. Whether you are automating complex processes or managing simple tasks, the GE Fanuc provides the reliability and performance needed to drive operational success.

Comparison with Other Models:

When compared to other models in the GE lineup, such as the GE SR750 or GE IC697MDL740, the GE Fanuc distinguishes itself with its superior processing speed and flexibility. While the GE SR750 offers strong performance for high-demand applications, the GE Fanuc's modular approach provides users with more customization options. Similarly, while the GE IS200DSPXH2DBD is built for specific industrial applications, the GE Fanuc serves a broader range of automation needs, making it a more versatile choice for businesses looking to future-proof their operations.

Related Models:

For customers seeking alternatives or complementary products within the GE automation family, consider the following models: GE IS200EDFFH1ABA, GE IC693APU301, GE IC660BBA020, and GE IS200TRPGH1BDE. Each of these models offers unique specifications that cater to various automation needs. The GE IC200CPU005 and GE IC695CPE310-ABAH are excellent for those requiring integrated control solutions. Meanwhile, the GE DS200DDTBG2A and GE DS200SIOCG1A excel in I/O connectivity, making them ideal for applications that demand extensive data handling. Additionally, users may explore the GE IS220PPDAH1A and GE IC694PWR331 for more specialized functions.

In conclusion, the GE Fanuc is a powerful, flexible solution designed to meet the diverse needs of industries today. With its advanced technical features and broad range

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.