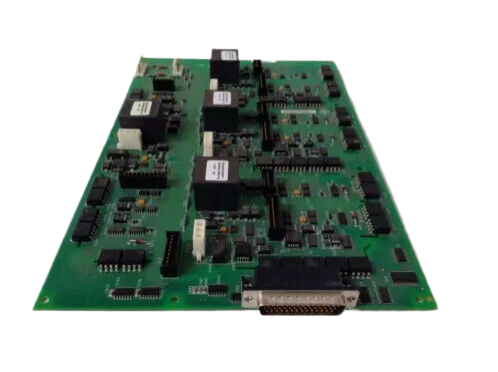

GE Fanuc IC695PSD140G Power Supply Module Reliable and High-Performance Electronics for Industrial Control

Introducing the GE Fanuc Model: A Pinnacle of Automation Technology

The GE Fanuc stands as a leading solution in the realm of industrial automation, renowned for its reliability, efficiency, and advanced features. Designed to meet the rigorous demands of various sectors, including manufacturing, transportation, and energy, this model integrates seamlessly into existing systems to enhance performance and productivity.

Key Technical Features

At the heart of the GE Fanuc model is its advanced processing capabilities, which are powered by a robust architecture designed for high-speed operations. The model boasts a flexible I/O configuration that allows for extensive scalability, accommodating both small and large applications. With support for multiple communication protocols, including Ethernet and serial connections, the GE Fanuc ensures seamless integration with other GE automation products and third-party systems.

Additionally, the GE Fanuc is equipped with diagnostic tools and built-in redundancy features that promote uptime and reliability. The model also supports extensive data logging and real-time monitoring, enabling operators to track system performance and troubleshoot issues proactively. Enhanced security features safeguard against unauthorized access, ensuring the integrity of critical operations.

Usage Scenarios

The versatility of the GE Fanuc makes it suitable for a wide range of applications. In manufacturing, it can control assembly lines, monitor production processes, and optimize workflows. In the energy sector, it manages power distribution and enhances grid reliability. For transportation, the GE Fanuc can be integrated into traffic management systems, improving efficiency and safety.

Moreover, the model is ideal for process industries, including oil and gas, where it can monitor complex operations and ensure compliance with safety standards. Whether deployed in a factory, power plant, or transportation hub, the GE Fanuc enhances operational efficiency and minimizes downtime, allowing businesses to achieve their goals more effectively.

Comparison with Other Models

When comparing the GE Fanuc to other models within the GE automation products lineup, it stands out for its balance of performance and usability. For instance, while the GE SR750 offers advanced motion control capabilities, the GE Fanuc excels in versatility and broader application compatibility. The IS200DSFCG1AEB model, known for its specific function in turbine control, may not offer the same level of flexibility as the GE Fanuc, which is designed for multifaceted industrial environments.

Additionally, the GE IC693APU301 is geared towards specific control applications, whereas the GE Fanuc provides a comprehensive solution adaptable to various operational needs. By evaluating different models, users can select the GE Fanuc for projects requiring a robust, all-encompassing automation solution.

Related Models

To provide context on the breadth of the GE automation products range, here are ten related models that complement the GE Fanuc:

1. GE SR750 – Ideal for motion control applications.

2. GE IC697MDL740 – A reliable modular I/O solution.

3. GE IS200DSFCG1AEB – Engineered for turbine control applications.

4. GE IC660BBA020 – A versatile base for data acquisition.

5. GE IS

The above parameters are for reference only. Please contact our technical team for precise selection.

The GE Fanuc stands as a leading solution in the realm of industrial automation, renowned for its reliability, efficiency, and advanced features. Designed to meet the rigorous demands of various sectors, including manufacturing, transportation, and energy, this model integrates seamlessly into existing systems to enhance performance and productivity.

Key Technical Features

At the heart of the GE Fanuc model is its advanced processing capabilities, which are powered by a robust architecture designed for high-speed operations. The model boasts a flexible I/O configuration that allows for extensive scalability, accommodating both small and large applications. With support for multiple communication protocols, including Ethernet and serial connections, the GE Fanuc ensures seamless integration with other GE automation products and third-party systems.

Additionally, the GE Fanuc is equipped with diagnostic tools and built-in redundancy features that promote uptime and reliability. The model also supports extensive data logging and real-time monitoring, enabling operators to track system performance and troubleshoot issues proactively. Enhanced security features safeguard against unauthorized access, ensuring the integrity of critical operations.

Usage Scenarios

The versatility of the GE Fanuc makes it suitable for a wide range of applications. In manufacturing, it can control assembly lines, monitor production processes, and optimize workflows. In the energy sector, it manages power distribution and enhances grid reliability. For transportation, the GE Fanuc can be integrated into traffic management systems, improving efficiency and safety.

Moreover, the model is ideal for process industries, including oil and gas, where it can monitor complex operations and ensure compliance with safety standards. Whether deployed in a factory, power plant, or transportation hub, the GE Fanuc enhances operational efficiency and minimizes downtime, allowing businesses to achieve their goals more effectively.

Comparison with Other Models

When comparing the GE Fanuc to other models within the GE automation products lineup, it stands out for its balance of performance and usability. For instance, while the GE SR750 offers advanced motion control capabilities, the GE Fanuc excels in versatility and broader application compatibility. The IS200DSFCG1AEB model, known for its specific function in turbine control, may not offer the same level of flexibility as the GE Fanuc, which is designed for multifaceted industrial environments.

Additionally, the GE IC693APU301 is geared towards specific control applications, whereas the GE Fanuc provides a comprehensive solution adaptable to various operational needs. By evaluating different models, users can select the GE Fanuc for projects requiring a robust, all-encompassing automation solution.

Related Models

To provide context on the breadth of the GE automation products range, here are ten related models that complement the GE Fanuc:

1. GE SR750 – Ideal for motion control applications.

2. GE IC697MDL740 – A reliable modular I/O solution.

3. GE IS200DSFCG1AEB – Engineered for turbine control applications.

4. GE IC660BBA020 – A versatile base for data acquisition.

5. GE IS

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.