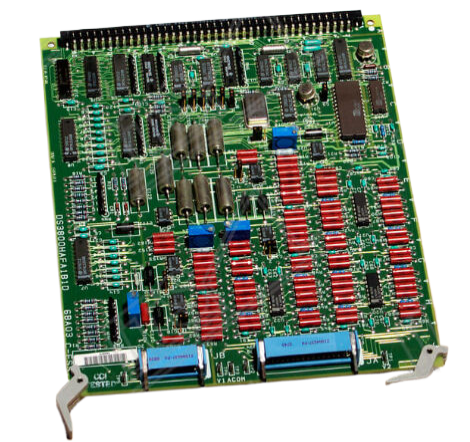

GE Fanuc IC695CRU320CD Programmable Automation Controller

Introducing the GE Fanuc: A Benchmark in Industrial Automation

When it comes to industrial automation, the GE Fanuc series stands as a testament to reliability, efficiency, and innovation. Engineered by the renowned General Electric brand, this range of automation products is designed to enhance productivity and streamline operations in various industries. The GE Fanuc models integrate cutting-edge technology with user-friendly interfaces, making them an ideal choice for both seasoned professionals and newcomers in the field.

Key Technical Features

The GE Fanuc models boast an array of impressive features that set them apart from the competition. Key specifications include robust processing power, extensive communication capabilities, and advanced diagnostic functions. With high-speed processing units, these devices can handle complex calculations and data management tasks effectively, ensuring seamless operations in real-time environments.

The GE Fanuc systems are equipped with versatile I/O modules that facilitate easy integration with existing machinery. This flexibility allows operators to customize their configurations according to specific application requirements. Additionally, the systems support various communication protocols, including Ethernet, Profibus, and DeviceNet, ensuring compatibility with a wide range of industrial devices.

Furthermore, GE Fanuc automation products are designed with built-in redundancy features, providing enhanced reliability and minimizing the risk of downtime. The intuitive programming environment simplifies the development of complex automation processes, empowering users to create tailored solutions for their operations.

Usage Scenarios

The versatility of the GE Fanuc models makes them suitable for a multitude of applications across diverse industries. In manufacturing, these systems can control assembly lines, monitor production processes, and manage inventory effectively. In the oil and gas sector, the GE Fanuc models can oversee drilling operations, pipeline monitoring, and safety systems to ensure compliance with industry regulations.

In the automotive industry, the GE Fanuc series can be employed to automate assembly processes, enhancing speed and precision. In the food and beverage sector, these systems can optimize packaging, labeling, and quality control processes to maintain high standards of hygiene and safety.

Moreover, the GE Fanuc systems are ideal for machine builders seeking reliable solutions for their equipment. With their robust architecture and flexible configurations, engineers can integrate GE Fanuc products into new machinery designs, ensuring optimal performance and long-term durability.

Comparison with Other Models

When comparing the GE Fanuc models with other automation products on the market, one notable advantage is their comprehensive support for various industrial protocols. While competing products may offer limited compatibility, GE Fanuc systems are designed to work seamlessly with existing infrastructure, reducing integration costs and time.

Additionally, the reliability of GE Fanuc models is well-documented, with many users reporting extended lifecycles and reduced maintenance needs. For instance, while models like the GE IC697MDL740 and GE IS200DSPXH2DBD provide excellent performance, the GE Fanuc series offers superior processing capabilities and diagnostic features that can result in lower downtime.

The GE SR750, for example, is renowned for its scalability, making it an excellent choice for businesses planning for future growth. In contrast, the GE

The above parameters are for reference only. Please contact our technical team for precise selection.

When it comes to industrial automation, the GE Fanuc series stands as a testament to reliability, efficiency, and innovation. Engineered by the renowned General Electric brand, this range of automation products is designed to enhance productivity and streamline operations in various industries. The GE Fanuc models integrate cutting-edge technology with user-friendly interfaces, making them an ideal choice for both seasoned professionals and newcomers in the field.

Key Technical Features

The GE Fanuc models boast an array of impressive features that set them apart from the competition. Key specifications include robust processing power, extensive communication capabilities, and advanced diagnostic functions. With high-speed processing units, these devices can handle complex calculations and data management tasks effectively, ensuring seamless operations in real-time environments.

The GE Fanuc systems are equipped with versatile I/O modules that facilitate easy integration with existing machinery. This flexibility allows operators to customize their configurations according to specific application requirements. Additionally, the systems support various communication protocols, including Ethernet, Profibus, and DeviceNet, ensuring compatibility with a wide range of industrial devices.

Furthermore, GE Fanuc automation products are designed with built-in redundancy features, providing enhanced reliability and minimizing the risk of downtime. The intuitive programming environment simplifies the development of complex automation processes, empowering users to create tailored solutions for their operations.

Usage Scenarios

The versatility of the GE Fanuc models makes them suitable for a multitude of applications across diverse industries. In manufacturing, these systems can control assembly lines, monitor production processes, and manage inventory effectively. In the oil and gas sector, the GE Fanuc models can oversee drilling operations, pipeline monitoring, and safety systems to ensure compliance with industry regulations.

In the automotive industry, the GE Fanuc series can be employed to automate assembly processes, enhancing speed and precision. In the food and beverage sector, these systems can optimize packaging, labeling, and quality control processes to maintain high standards of hygiene and safety.

Moreover, the GE Fanuc systems are ideal for machine builders seeking reliable solutions for their equipment. With their robust architecture and flexible configurations, engineers can integrate GE Fanuc products into new machinery designs, ensuring optimal performance and long-term durability.

Comparison with Other Models

When comparing the GE Fanuc models with other automation products on the market, one notable advantage is their comprehensive support for various industrial protocols. While competing products may offer limited compatibility, GE Fanuc systems are designed to work seamlessly with existing infrastructure, reducing integration costs and time.

Additionally, the reliability of GE Fanuc models is well-documented, with many users reporting extended lifecycles and reduced maintenance needs. For instance, while models like the GE IC697MDL740 and GE IS200DSPXH2DBD provide excellent performance, the GE Fanuc series offers superior processing capabilities and diagnostic features that can result in lower downtime.

The GE SR750, for example, is renowned for its scalability, making it an excellent choice for businesses planning for future growth. In contrast, the GE

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.