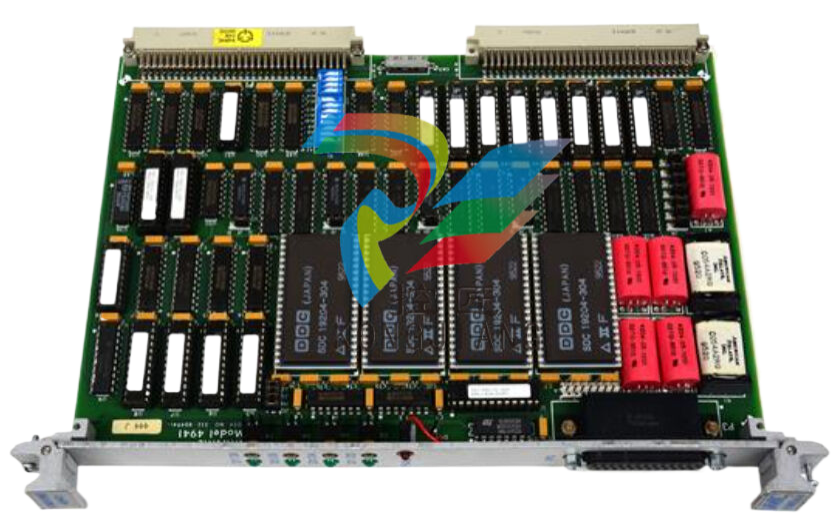

GE Fanuc IC694MDL646 PAC Systems RX3i Advanced Modular Programmable Automation Controller

Introducing the GE Fanuc: the pinnacle of industrial automation technology. Renowned for its exceptional performance and reliability, the GE Fanuc is engineered to meet the demands of modern manufacturing and process control environments. With a robust suite of technical features, diverse usage scenarios, and competitive advantages over other models, the GE Fanuc stands out as a leader in the GE automation products lineup.

Key Technical Features

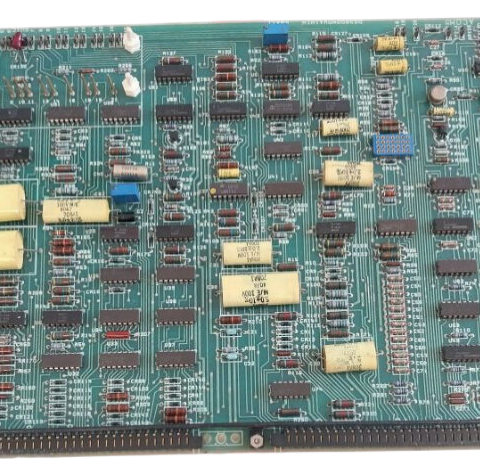

The GE Fanuc is equipped with advanced capabilities that facilitate seamless integration and operation within various industrial systems. The model boasts high processing speeds, allowing it to handle complex tasks swiftly and efficiently. Its modular architecture provides flexibility, enabling users to customize their systems according to specific operational needs. The GE Fanuc also features extensive networking capabilities, supporting various communication protocols to ensure compatibility with existing infrastructure. Enhanced diagnostics and troubleshooting functionalities are built-in, simplifying maintenance and minimizing downtime.

In terms of input/output (I/O) options, the GE Fanuc supports a wide range of modules catering to diverse applications, from simple control tasks to sophisticated automation processes. The unit is designed to withstand harsh industrial environments, ensuring durability and longevity. With advanced safety features, the GE Fanuc prioritizes operational safety, making it an ideal choice for critical applications.

Usage Scenarios

The versatility of the GE Fanuc is evident in its applicability across various industries. It is an excellent choice for manufacturing plants, where it can streamline production lines and enhance efficiency. In process control environments, the GE Fanuc can monitor and regulate operations, ensuring optimal performance and adherence to quality standards. Its robust features make it suitable for applications in automotive, food and beverage, pharmaceuticals, and more.

Furthermore, the GE Fanuc is perfect for applications requiring real-time data processing and analysis. Industries that demand quick decision-making, such as energy management and telecommunications, benefit from the model's rapid response capabilities. The GE Fanuc not only enhances productivity but also provides valuable insights through data collection and analytics, leading to informed operational decisions.

Comparison with Other Models

When compared to other models within the GE automation products range, such as the GE SR750 and the GE IC697MDL740, the GE Fanuc emerges as a superior option for those seeking advanced automation functionalities. While the SR750 offers solid performance for basic applications, the GE Fanuc's enhanced processing capabilities and flexibility give it a competitive edge in more complex scenarios.

Similarly, compared to models like the GE IS200DSPXH2DBD and the GE DS200DDTBG2A, the GE Fanuc excels in networking capabilities, allowing for smoother integration with other devices and systems. Its modular design also sets it apart from more rigid models, offering users the ability to expand and adapt their systems as requirements evolve.

Related Models

To provide a comprehensive understanding of the GE automation products ecosystem, it's essential to mention related models such as the GE IS200EDFFH1ABA, GE IC200CPU005, and GE IS200VTURH1BAC. Each of these models serves specific purposes

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE Fanuc is equipped with advanced capabilities that facilitate seamless integration and operation within various industrial systems. The model boasts high processing speeds, allowing it to handle complex tasks swiftly and efficiently. Its modular architecture provides flexibility, enabling users to customize their systems according to specific operational needs. The GE Fanuc also features extensive networking capabilities, supporting various communication protocols to ensure compatibility with existing infrastructure. Enhanced diagnostics and troubleshooting functionalities are built-in, simplifying maintenance and minimizing downtime.

In terms of input/output (I/O) options, the GE Fanuc supports a wide range of modules catering to diverse applications, from simple control tasks to sophisticated automation processes. The unit is designed to withstand harsh industrial environments, ensuring durability and longevity. With advanced safety features, the GE Fanuc prioritizes operational safety, making it an ideal choice for critical applications.

Usage Scenarios

The versatility of the GE Fanuc is evident in its applicability across various industries. It is an excellent choice for manufacturing plants, where it can streamline production lines and enhance efficiency. In process control environments, the GE Fanuc can monitor and regulate operations, ensuring optimal performance and adherence to quality standards. Its robust features make it suitable for applications in automotive, food and beverage, pharmaceuticals, and more.

Furthermore, the GE Fanuc is perfect for applications requiring real-time data processing and analysis. Industries that demand quick decision-making, such as energy management and telecommunications, benefit from the model's rapid response capabilities. The GE Fanuc not only enhances productivity but also provides valuable insights through data collection and analytics, leading to informed operational decisions.

Comparison with Other Models

When compared to other models within the GE automation products range, such as the GE SR750 and the GE IC697MDL740, the GE Fanuc emerges as a superior option for those seeking advanced automation functionalities. While the SR750 offers solid performance for basic applications, the GE Fanuc's enhanced processing capabilities and flexibility give it a competitive edge in more complex scenarios.

Similarly, compared to models like the GE IS200DSPXH2DBD and the GE DS200DDTBG2A, the GE Fanuc excels in networking capabilities, allowing for smoother integration with other devices and systems. Its modular design also sets it apart from more rigid models, offering users the ability to expand and adapt their systems as requirements evolve.

Related Models

To provide a comprehensive understanding of the GE automation products ecosystem, it's essential to mention related models such as the GE IS200EDFFH1ABA, GE IC200CPU005, and GE IS200VTURH1BAC. Each of these models serves specific purposes

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.