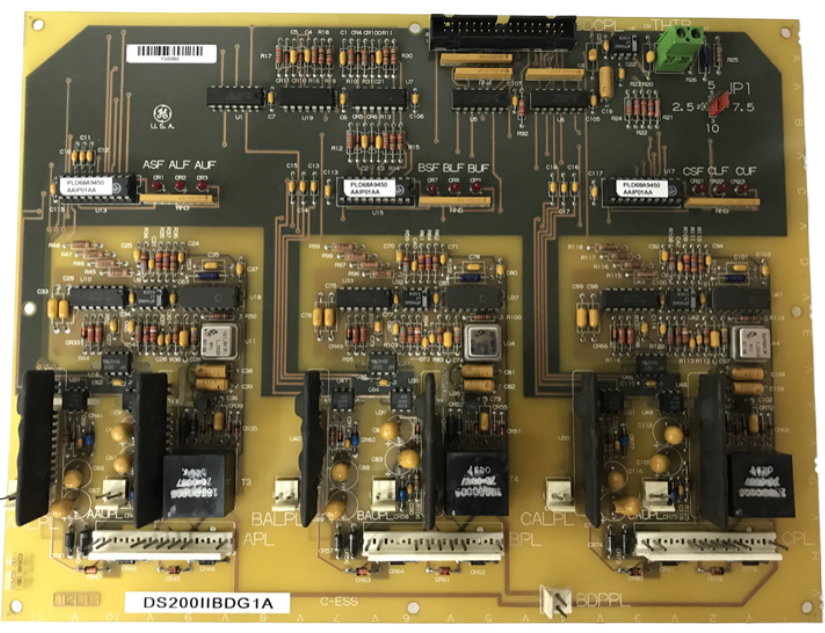

GE FANUC IC693MDL654 Modular Control System

Introducing the GE FANUC: a pivotal component in the realm of industrial automation, designed to provide unparalleled performance and reliability in various applications. Renowned for its innovative engineering, the GE FANUC series stands as a testament to GE’s commitment to excellence in automation products.

Key Technical Features

At the core of the GE FANUC is its cutting-edge technology, which includes high processing speeds and exceptional data handling capabilities. The model boasts advanced communication protocols, ensuring seamless integration with existing systems. With a robust architecture, it supports a wide array of I/O configurations, making it highly adaptable to various industrial environments. Moreover, the GE FANUC features enhanced diagnostics and monitoring tools that facilitate real-time data analysis, enabling users to optimize operational efficiency and minimize downtime. Its compact design ensures easy installation while maximizing space within control panels.

Usage Scenarios

The versatility of the GE FANUC makes it suitable for a plethora of applications across different industries. In manufacturing, it can be utilized for process control, enabling precise management of machinery and production lines. The GE FANUC is also ideal for motion control applications, where accurate positioning and speed control are critical. In energy management, it assists in monitoring and controlling electrical systems, ensuring optimal performance while reducing energy consumption. Whether deployed in automotive, aerospace, or food processing sectors, the GE FANUC excels in enhancing operational productivity and reliability.

Comparison with Other Models

When comparing the GE FANUC with other models in the GE lineup, such as the GE IS200TPROH1BCB or the GE IC697MDL653, the GE FANUC is distinguished by its superior processing capabilities and advanced communication features. While the IS200TPROH1BCB is tailored for specific control applications, the GE FANUC offers a more versatile platform suitable for a broader range of tasks. Additionally, unlike the IC697MDL653, which is focused on modular I/O control, the GE FANUC integrates multiple functionalities into a single unit, streamlining processes and reducing the need for additional components.

Related Models

For those exploring GE automation products, consider these related models, each bringing unique strengths to the table: the GE IS200TBCIH1BBC, which excels in robust control tasks; the GE IS220PPROS1B, known for precise process control; the GE CT7P70500470CW24, which provides exceptional reliability in harsh environments; and the GE EVMECNTM13, ideal for extensive monitoring applications. Other notable mentions include the GE IC660ELB912G, GE DS200CTBAG1ADD, GE HE693STP110, and GE IC660EBD020, each contributing to the expansive ecosystem of GE automation solutions.

SEO Keywords

In the ever-evolving landscape of industrial automation, the GE FANUC continues to be a cornerstone of reliability and efficiency. As organizations increasingly seek to enhance their productivity, the demand for GE automation products, including the GE FANUC, is on the rise. Its adaptability and robust performance make it an invaluable resource for companies looking to streamline their processes and elevate their operational capabilities.

In summary, the GE FANUC represents the pinnacle of automation technology, merging advanced features with versatile applications. Its ability to perform under diverse conditions, coupled with its integrations with other GE models, positions it as a market leader in automation solutions. For businesses aiming to optimize their operations and embrace the future of industrial automation, the GE FANUC is an investment that pays dividends in efficiency and performance.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

At the core of the GE FANUC is its cutting-edge technology, which includes high processing speeds and exceptional data handling capabilities. The model boasts advanced communication protocols, ensuring seamless integration with existing systems. With a robust architecture, it supports a wide array of I/O configurations, making it highly adaptable to various industrial environments. Moreover, the GE FANUC features enhanced diagnostics and monitoring tools that facilitate real-time data analysis, enabling users to optimize operational efficiency and minimize downtime. Its compact design ensures easy installation while maximizing space within control panels.

Usage Scenarios

The versatility of the GE FANUC makes it suitable for a plethora of applications across different industries. In manufacturing, it can be utilized for process control, enabling precise management of machinery and production lines. The GE FANUC is also ideal for motion control applications, where accurate positioning and speed control are critical. In energy management, it assists in monitoring and controlling electrical systems, ensuring optimal performance while reducing energy consumption. Whether deployed in automotive, aerospace, or food processing sectors, the GE FANUC excels in enhancing operational productivity and reliability.

Comparison with Other Models

When comparing the GE FANUC with other models in the GE lineup, such as the GE IS200TPROH1BCB or the GE IC697MDL653, the GE FANUC is distinguished by its superior processing capabilities and advanced communication features. While the IS200TPROH1BCB is tailored for specific control applications, the GE FANUC offers a more versatile platform suitable for a broader range of tasks. Additionally, unlike the IC697MDL653, which is focused on modular I/O control, the GE FANUC integrates multiple functionalities into a single unit, streamlining processes and reducing the need for additional components.

Related Models

For those exploring GE automation products, consider these related models, each bringing unique strengths to the table: the GE IS200TBCIH1BBC, which excels in robust control tasks; the GE IS220PPROS1B, known for precise process control; the GE CT7P70500470CW24, which provides exceptional reliability in harsh environments; and the GE EVMECNTM13, ideal for extensive monitoring applications. Other notable mentions include the GE IC660ELB912G, GE DS200CTBAG1ADD, GE HE693STP110, and GE IC660EBD020, each contributing to the expansive ecosystem of GE automation solutions.

SEO Keywords

In the ever-evolving landscape of industrial automation, the GE FANUC continues to be a cornerstone of reliability and efficiency. As organizations increasingly seek to enhance their productivity, the demand for GE automation products, including the GE FANUC, is on the rise. Its adaptability and robust performance make it an invaluable resource for companies looking to streamline their processes and elevate their operational capabilities.

In summary, the GE FANUC represents the pinnacle of automation technology, merging advanced features with versatile applications. Its ability to perform under diverse conditions, coupled with its integrations with other GE models, positions it as a market leader in automation solutions. For businesses aiming to optimize their operations and embrace the future of industrial automation, the GE FANUC is an investment that pays dividends in efficiency and performance.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.