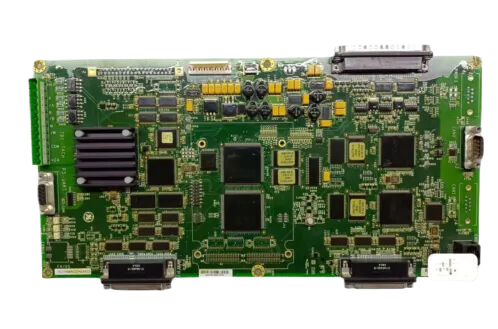

GE FANUC IC693CPU360 Central Processing Unit (CPU) 360 Module

Introducing the GE FANUC, a premier solution in the realm of industrial automation designed to enhance operational efficiency and reliability across various sectors. GE FANUC stands out as a robust platform equipped with advanced features that cater to the demanding needs of modern manufacturing and process control environments.

Key Technical Features:

The GE FANUC series is renowned for its high-performance capabilities, which include a powerful processing unit that supports real-time operations, ensuring quick data processing and reduced latency in system response. With a modular architecture, it allows for easy scalability and customization, making it an ideal choice for both small-scale operations and large industrial setups. The system supports a wide range of I/O modules, enabling seamless integration with existing hardware and facilitating versatile applications. Additionally, the GE FANUC boasts comprehensive communication protocols that ensure connectivity with other GE automation products and third-party devices, enhancing interoperability and system cohesiveness.

Usage Scenarios:

The versatility of the GE FANUC makes it suitable for a variety of applications, including discrete manufacturing, process control, and robotics. In automotive assembly lines, it efficiently manages complex machinery, facilitating smooth operations and improving production timelines. In the food and beverage industry, the GE FANUC ensures precise control over processes, maintaining stringent quality standards while optimizing resources. Furthermore, in the energy sector, it plays a crucial role in monitoring and controlling critical systems, ensuring reliability and safety in operations.

Comparison with Other Models:

When compared to other models such as the GE SR750 and GE IS200 series, the GE FANUC distinguishes itself through its superior processing speed and enhanced connectivity options. While the GE SR750 is focused on specific applications, the GE FANUC offers a more flexible solution that adapts to a broader range of industrial needs. The IC697MDL740 model, known for its reliability, may be a strong contender, but it lacks the advanced communication features found in the GE FANUC, limiting its integration capabilities. The GE IS200DSPXH2DBD model, while robust, does not match the modularity and scalability that the GE FANUC provides, making the latter a more future-proof choice for businesses looking to expand their automation systems.

Related Models:

For those exploring the GE automation product lineup, consider the following related models: GE SR750, GE IC697MDL740, GE IS200DSFCG1AEB, GE IC660BBA020, GE DS200DDTBG2A, GE IS200DSPXH2DBD, GE IS220PPDAH1A, GE IC693APU301, GE IC200CPU005, and GE IC695CPE310-ABAH. Each of these models presents unique features that cater to specific industrial requirements, but the GE FANUC remains the go-to solution for a comprehensive and adaptable automation platform.

In conclusion, the GE FANUC is engineered to meet the dynamic demands of modern industries, offering a harmonious blend of performance, versatility, and connectivity. Its ability to integrate seamlessly with other GE automation products ensures that it

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE FANUC series is renowned for its high-performance capabilities, which include a powerful processing unit that supports real-time operations, ensuring quick data processing and reduced latency in system response. With a modular architecture, it allows for easy scalability and customization, making it an ideal choice for both small-scale operations and large industrial setups. The system supports a wide range of I/O modules, enabling seamless integration with existing hardware and facilitating versatile applications. Additionally, the GE FANUC boasts comprehensive communication protocols that ensure connectivity with other GE automation products and third-party devices, enhancing interoperability and system cohesiveness.

Usage Scenarios:

The versatility of the GE FANUC makes it suitable for a variety of applications, including discrete manufacturing, process control, and robotics. In automotive assembly lines, it efficiently manages complex machinery, facilitating smooth operations and improving production timelines. In the food and beverage industry, the GE FANUC ensures precise control over processes, maintaining stringent quality standards while optimizing resources. Furthermore, in the energy sector, it plays a crucial role in monitoring and controlling critical systems, ensuring reliability and safety in operations.

Comparison with Other Models:

When compared to other models such as the GE SR750 and GE IS200 series, the GE FANUC distinguishes itself through its superior processing speed and enhanced connectivity options. While the GE SR750 is focused on specific applications, the GE FANUC offers a more flexible solution that adapts to a broader range of industrial needs. The IC697MDL740 model, known for its reliability, may be a strong contender, but it lacks the advanced communication features found in the GE FANUC, limiting its integration capabilities. The GE IS200DSPXH2DBD model, while robust, does not match the modularity and scalability that the GE FANUC provides, making the latter a more future-proof choice for businesses looking to expand their automation systems.

Related Models:

For those exploring the GE automation product lineup, consider the following related models: GE SR750, GE IC697MDL740, GE IS200DSFCG1AEB, GE IC660BBA020, GE DS200DDTBG2A, GE IS200DSPXH2DBD, GE IS220PPDAH1A, GE IC693APU301, GE IC200CPU005, and GE IC695CPE310-ABAH. Each of these models presents unique features that cater to specific industrial requirements, but the GE FANUC remains the go-to solution for a comprehensive and adaptable automation platform.

In conclusion, the GE FANUC is engineered to meet the dynamic demands of modern industries, offering a harmonious blend of performance, versatility, and connectivity. Its ability to integrate seamlessly with other GE automation products ensures that it

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.