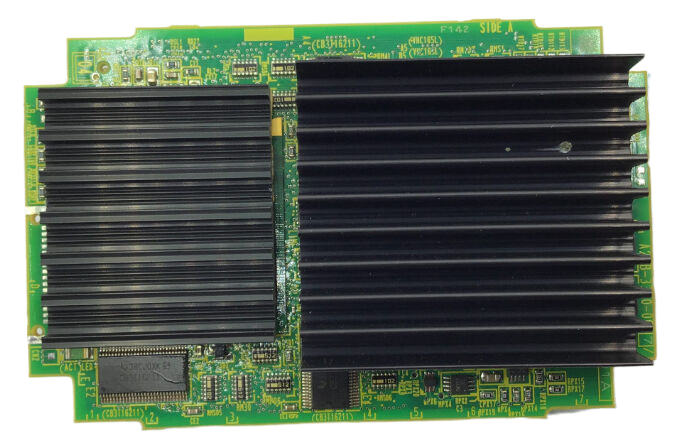

GE FANUC IC693CHS392J High Performance Expansion Base Plate

Introducing the GE FANUC, a powerhouse in the realm of industrial automation designed to enhance operational efficiency and reliability across various applications. Renowned for its robust performance and innovative technology, the GE FANUC model stands out as a vital asset for industries seeking to streamline their processes and improve productivity.

Key Technical Features

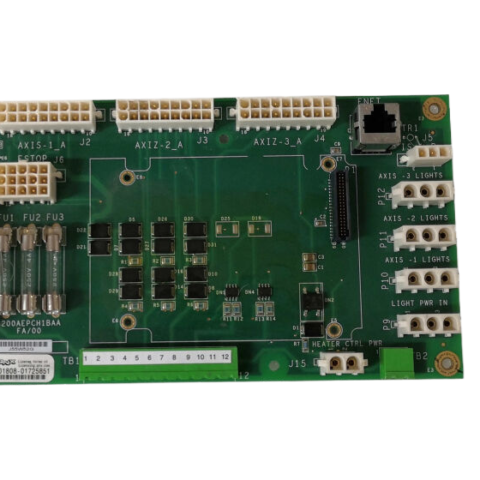

The GE FANUC is equipped with advanced features that cater to the demands of modern automation systems. With a high-speed processing unit and extensive memory capabilities, this model delivers unparalleled performance in real-time data processing and control. It supports multiple communication protocols, ensuring seamless integration with existing systems and devices. The GE FANUC also incorporates advanced diagnostics and troubleshooting capabilities, which simplify maintenance and reduce downtime. Its modular design allows for easy scalability and customization, enabling businesses to adapt the system to their specific needs. Additionally, the GE FANUC operates in a wide temperature range, making it suitable for diverse industrial environments.

Usage Scenarios

The versatility of the GE FANUC makes it an ideal choice for a variety of applications across different sectors. In manufacturing, it can be used for process control, machine automation, and robotics, enhancing efficiency and precision. In the energy sector, the GE FANUC plays a critical role in monitoring and controlling power generation and distribution systems, ensuring optimal performance and reliability. The transportation industry benefits from its use in traffic control systems and logistics management, where real-time data processing is essential. Moreover, the GE FANUC is widely utilized in the food and beverage industry for process automation and quality control, helping to maintain high standards and compliance with regulations.

Comparison with Other Models

When comparing the GE FANUC to other models within the GE portfolio, such as the GE SR750 or the GE IC697MDL740, it becomes evident that the GE FANUC offers superior processing capabilities and a more extensive range of communication options. While the GE SR750 excels in specific applications requiring high-speed control, the GE FANUC's versatility allows it to adapt to a broader range of scenarios. In contrast to the GE IS200DSPXH2DBD and the GE DS200DDTBG2A, which are tailored for specific industrial tasks, the GE FANUC provides a more comprehensive solution that can handle multiple functions across various sectors. Its modularity also distinguishes it from models like the GE IC660BBA020 and GE IS220PPDAH1A, offering greater customization to meet unique operational requirements.

Related Models

To further illustrate the breadth of GE's automation offerings, here are ten related models that complement the GE FANUC:

1. GE SR750 – High-performance CPU for demanding applications.

2. GE IC697MDL740 – Versatile I/O module for various control systems.

3. GE IS200DSFCG1AEB – Digital signal processor for enhanced control.

4. GE IC660BBA020 – Analog input module for precise data acquisition.

5. GE DS200DDTBG2A – Digital output module designed for reliability.

6. GE IS200DSP

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE FANUC is equipped with advanced features that cater to the demands of modern automation systems. With a high-speed processing unit and extensive memory capabilities, this model delivers unparalleled performance in real-time data processing and control. It supports multiple communication protocols, ensuring seamless integration with existing systems and devices. The GE FANUC also incorporates advanced diagnostics and troubleshooting capabilities, which simplify maintenance and reduce downtime. Its modular design allows for easy scalability and customization, enabling businesses to adapt the system to their specific needs. Additionally, the GE FANUC operates in a wide temperature range, making it suitable for diverse industrial environments.

Usage Scenarios

The versatility of the GE FANUC makes it an ideal choice for a variety of applications across different sectors. In manufacturing, it can be used for process control, machine automation, and robotics, enhancing efficiency and precision. In the energy sector, the GE FANUC plays a critical role in monitoring and controlling power generation and distribution systems, ensuring optimal performance and reliability. The transportation industry benefits from its use in traffic control systems and logistics management, where real-time data processing is essential. Moreover, the GE FANUC is widely utilized in the food and beverage industry for process automation and quality control, helping to maintain high standards and compliance with regulations.

Comparison with Other Models

When comparing the GE FANUC to other models within the GE portfolio, such as the GE SR750 or the GE IC697MDL740, it becomes evident that the GE FANUC offers superior processing capabilities and a more extensive range of communication options. While the GE SR750 excels in specific applications requiring high-speed control, the GE FANUC's versatility allows it to adapt to a broader range of scenarios. In contrast to the GE IS200DSPXH2DBD and the GE DS200DDTBG2A, which are tailored for specific industrial tasks, the GE FANUC provides a more comprehensive solution that can handle multiple functions across various sectors. Its modularity also distinguishes it from models like the GE IC660BBA020 and GE IS220PPDAH1A, offering greater customization to meet unique operational requirements.

Related Models

To further illustrate the breadth of GE's automation offerings, here are ten related models that complement the GE FANUC:

1. GE SR750 – High-performance CPU for demanding applications.

2. GE IC697MDL740 – Versatile I/O module for various control systems.

3. GE IS200DSFCG1AEB – Digital signal processor for enhanced control.

4. GE IC660BBA020 – Analog input module for precise data acquisition.

5. GE DS200DDTBG2A – Digital output module designed for reliability.

6. GE IS200DSP

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.