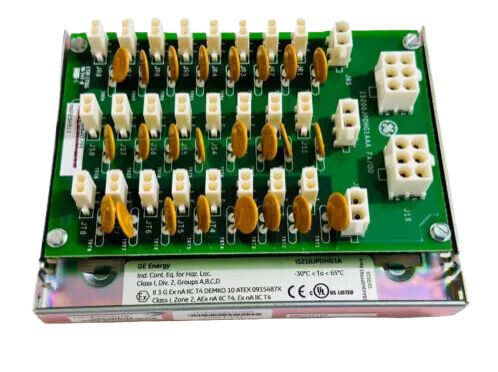

GE Fanuc IC693ACC307 Modular Control Module for Efficient I/O Bus Termination

Introducing the GE Fanuc, a pinnacle of engineering excellence in the realm of automation technology. Renowned for its reliability and advanced features, the GE Fanuc series is designed to meet the demanding needs of various industries, including manufacturing, energy, and transportation. With state-of-the-art capabilities, the GE Fanuc stands out as an essential component in your automation toolkit, streamlining processes and enhancing operational efficiency.

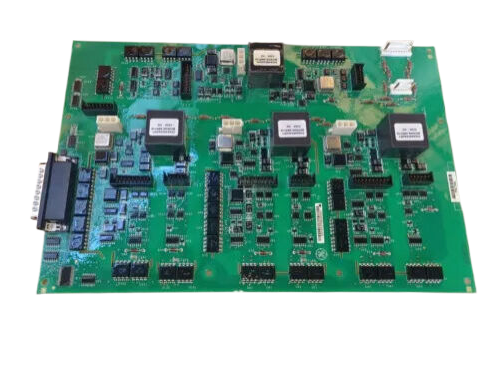

Key technical features of the GE Fanuc include robust processing power, versatile communication options, and superior diagnostic capabilities. The model supports multiple programming languages, allowing for flexible integration into existing systems. Equipped with a high-performance CPU, the GE Fanuc ensures rapid data handling and real-time processing, which is critical for mission-critical applications. The system's modular design allows for easy expansion and upgrades, ensuring that it can adapt to the evolving demands of your operations.

One of the standout features is its advanced networking capabilities, which enable seamless communication with other GE automation products. This integration allows for enhanced data sharing and coordination across different components of your automation setup. Additionally, the GE Fanuc is built with redundancy features that ensure system reliability and minimize downtime.

Usage scenarios for the GE Fanuc are virtually limitless. In manufacturing, it can control complex assembly lines, monitor machinery health, and optimize production schedules. In the energy sector, the GE Fanuc is instrumental in managing distribution networks and facilitating real-time monitoring of grid performance. Transportation systems also benefit from its capabilities, where it can oversee traffic control systems, manage fleet operations, and enhance overall safety protocols.

When comparing the GE Fanuc to other models within the GE lineup, such as the GE IS200DSPXH1DBC or the GE IS220PPROS1B, it becomes clear that the GE Fanuc offers superior adaptability and performance. While the IS200DSPXH1DBC is excellent for specific applications, the GE Fanuc's versatility makes it a better choice for users who require a multi-functional system. Similarly, the IS220PPROS1B excels in process control, but the GE Fanuc's advanced networking capabilities provide a more comprehensive automation solution.

For those looking for specific features, the GE IS215UCVEH2AB offers dedicated control for industrial processes, while the GE IC697MDL250 focuses on I/O capabilities. However, the GE Fanuc's balance of processing power and communication options makes it a strong contender for businesses looking to future-proof their automation systems. The GE 369-HI-0-M-0-0-0 and the GE IS200TPROH1BBB are also excellent models but cater to niche applications, while the GE Fanuc serves a broader range of industrial needs.

In addition to the models previously mentioned, the GE IC693CPU374 and GE IC660ELB912 are noteworthy for their specific applications in control and data management. The GE IS200TPROH1BCB and GE IC670MDL640 are ideal for users who prioritize reliability and system integrity in their automation operations. Lastly, the GE DS200TCQAG1BHF provides advanced control features for specialized applications, whereas the GE Fanuc maintains a versatile approach suitable for various operational demands.

In conclusion, the GE Fanuc is a remarkable solution within the GE automation products suite, delivering exceptional performance and adaptability for a wide range of industries. Its advanced technical features, versatility in usage scenarios, and robust communication capabilities make it an ideal choice for businesses looking to enhance their automation processes. With a comprehensive range of models available, including the GE IS200TBCIH1BBC, GE CT7P70500470CW24, and GE IC698CMX016, the GE Fanuc ensures that you have the right tools to achieve operational excellence. Embrace the future of automation with GE Fanuc, where technology meets reliability.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key technical features of the GE Fanuc include robust processing power, versatile communication options, and superior diagnostic capabilities. The model supports multiple programming languages, allowing for flexible integration into existing systems. Equipped with a high-performance CPU, the GE Fanuc ensures rapid data handling and real-time processing, which is critical for mission-critical applications. The system's modular design allows for easy expansion and upgrades, ensuring that it can adapt to the evolving demands of your operations.

One of the standout features is its advanced networking capabilities, which enable seamless communication with other GE automation products. This integration allows for enhanced data sharing and coordination across different components of your automation setup. Additionally, the GE Fanuc is built with redundancy features that ensure system reliability and minimize downtime.

Usage scenarios for the GE Fanuc are virtually limitless. In manufacturing, it can control complex assembly lines, monitor machinery health, and optimize production schedules. In the energy sector, the GE Fanuc is instrumental in managing distribution networks and facilitating real-time monitoring of grid performance. Transportation systems also benefit from its capabilities, where it can oversee traffic control systems, manage fleet operations, and enhance overall safety protocols.

When comparing the GE Fanuc to other models within the GE lineup, such as the GE IS200DSPXH1DBC or the GE IS220PPROS1B, it becomes clear that the GE Fanuc offers superior adaptability and performance. While the IS200DSPXH1DBC is excellent for specific applications, the GE Fanuc's versatility makes it a better choice for users who require a multi-functional system. Similarly, the IS220PPROS1B excels in process control, but the GE Fanuc's advanced networking capabilities provide a more comprehensive automation solution.

For those looking for specific features, the GE IS215UCVEH2AB offers dedicated control for industrial processes, while the GE IC697MDL250 focuses on I/O capabilities. However, the GE Fanuc's balance of processing power and communication options makes it a strong contender for businesses looking to future-proof their automation systems. The GE 369-HI-0-M-0-0-0 and the GE IS200TPROH1BBB are also excellent models but cater to niche applications, while the GE Fanuc serves a broader range of industrial needs.

In addition to the models previously mentioned, the GE IC693CPU374 and GE IC660ELB912 are noteworthy for their specific applications in control and data management. The GE IS200TPROH1BCB and GE IC670MDL640 are ideal for users who prioritize reliability and system integrity in their automation operations. Lastly, the GE DS200TCQAG1BHF provides advanced control features for specialized applications, whereas the GE Fanuc maintains a versatile approach suitable for various operational demands.

In conclusion, the GE Fanuc is a remarkable solution within the GE automation products suite, delivering exceptional performance and adaptability for a wide range of industries. Its advanced technical features, versatility in usage scenarios, and robust communication capabilities make it an ideal choice for businesses looking to enhance their automation processes. With a comprehensive range of models available, including the GE IS200TBCIH1BBC, GE CT7P70500470CW24, and GE IC698CMX016, the GE Fanuc ensures that you have the right tools to achieve operational excellence. Embrace the future of automation with GE Fanuc, where technology meets reliability.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.