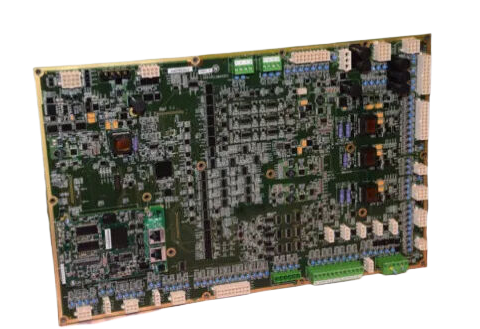

GE Fanuc IC670MDL740 Advanced PLC Module for Industrial Control Solutions

Introducing the GE Fanuc: a pinnacle in industrial automation solutions designed to improve efficiency, reliability, and productivity across diverse applications. With an extensive array of models under the GE brand, the GE Fanuc stands out for its advanced features and adaptability, making it a preferred choice among industry leaders.

Key Technical Features:

The GE Fanuc model is engineered with cutting-edge technology that supports a wide range of automation processes. It boasts high-performance processing capabilities, ensuring swift data handling and real-time decision-making. Equipped with robust communication protocols, the GE Fanuc facilitates seamless integration with other GE automation products and third-party systems, enhancing interoperability across your operational landscape. The model’s modular design promotes easy scalability, allowing businesses to expand their automation capabilities as their needs evolve. Additionally, it features extensive input/output options, enabling the connection of multiple devices and sensors, and supports various programming languages, ensuring flexibility for developers and engineers.

Usage Scenarios:

The versatility of the GE Fanuc makes it ideal for various industries, including manufacturing, energy, and transportation. In manufacturing, the GE Fanuc can be employed to automate assembly lines, control robotic arms, and manage production schedules, ultimately streamlining operations and reducing downtime. In the energy sector, it serves as a reliable controller for power generation and distribution systems, optimizing energy flow and ensuring safety protocols are followed. For transportation, the GE Fanuc can manage traffic systems and fleet operations, enhancing efficiency and safety on the roads. Its ability to connect with sensors and provide real-time data analysis makes it an invaluable tool in predictive maintenance, helping businesses avoid costly failures and extend the lifespan of their equipment.

Comparison with Other Models:

When compared to other GE models like the GE SR750, which focuses on advanced motion control, or the GE IC697MDL740, known for its flexibility in modular design, the GE Fanuc distinguishes itself with its exceptional processing power and extensive communication capabilities. While the GE IS200DSPXH2DBD offers specialized features for specific applications, the GE Fanuc is designed for broader use, making it a more versatile choice for companies looking to implement a comprehensive automation strategy. Additionally, when compared to models such as the GE IC200CPU005 or GE IC695CPE310-ABAH, the GE Fanuc's enhanced connectivity options make it more suited for modern industrial environments that demand robust data sharing and integration.

Related Models:

The GE Fanuc is part of an extensive lineup of GE automation products that cater to various industrial needs. Related models include the GE IS200EDFFH1ABA, which offers advanced digital input/output control, the GE IC660BBA020, designed for high-speed data processing, and the GE DS200DDTBG2A, which excels in digital signal processing. Furthermore, the GE IC693APU301 and GE IC694PWR331 provide powerful processing capabilities tailored for specific applications. Other notable models include the GE IS200VTURH1BAC for turbine control, the GE IS200TRPG

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE Fanuc model is engineered with cutting-edge technology that supports a wide range of automation processes. It boasts high-performance processing capabilities, ensuring swift data handling and real-time decision-making. Equipped with robust communication protocols, the GE Fanuc facilitates seamless integration with other GE automation products and third-party systems, enhancing interoperability across your operational landscape. The model’s modular design promotes easy scalability, allowing businesses to expand their automation capabilities as their needs evolve. Additionally, it features extensive input/output options, enabling the connection of multiple devices and sensors, and supports various programming languages, ensuring flexibility for developers and engineers.

Usage Scenarios:

The versatility of the GE Fanuc makes it ideal for various industries, including manufacturing, energy, and transportation. In manufacturing, the GE Fanuc can be employed to automate assembly lines, control robotic arms, and manage production schedules, ultimately streamlining operations and reducing downtime. In the energy sector, it serves as a reliable controller for power generation and distribution systems, optimizing energy flow and ensuring safety protocols are followed. For transportation, the GE Fanuc can manage traffic systems and fleet operations, enhancing efficiency and safety on the roads. Its ability to connect with sensors and provide real-time data analysis makes it an invaluable tool in predictive maintenance, helping businesses avoid costly failures and extend the lifespan of their equipment.

Comparison with Other Models:

When compared to other GE models like the GE SR750, which focuses on advanced motion control, or the GE IC697MDL740, known for its flexibility in modular design, the GE Fanuc distinguishes itself with its exceptional processing power and extensive communication capabilities. While the GE IS200DSPXH2DBD offers specialized features for specific applications, the GE Fanuc is designed for broader use, making it a more versatile choice for companies looking to implement a comprehensive automation strategy. Additionally, when compared to models such as the GE IC200CPU005 or GE IC695CPE310-ABAH, the GE Fanuc's enhanced connectivity options make it more suited for modern industrial environments that demand robust data sharing and integration.

Related Models:

The GE Fanuc is part of an extensive lineup of GE automation products that cater to various industrial needs. Related models include the GE IS200EDFFH1ABA, which offers advanced digital input/output control, the GE IC660BBA020, designed for high-speed data processing, and the GE DS200DDTBG2A, which excels in digital signal processing. Furthermore, the GE IC693APU301 and GE IC694PWR331 provide powerful processing capabilities tailored for specific applications. Other notable models include the GE IS200VTURH1BAC for turbine control, the GE IS200TRPG

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.