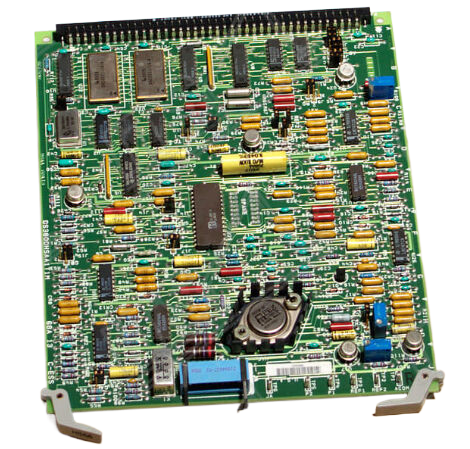

GE Fanuc IC600CB527M I/O Control Module

Introducing the GE Fanuc – the epitome of innovation in industrial automation. As part of the renowned GE family, the GE Fanuc is designed to meet the rigorous demands of modern manufacturing and process control environments. With a combination of advanced technology, reliability, and user-friendly features, this model stands out as a top choice for businesses aiming to enhance their operational efficiency.

Key Technical Features:

The GE Fanuc is equipped with an array of cutting-edge features that set it apart from competitors. It boasts high processing speeds, allowing for rapid data handling and control logic execution, essential for real-time applications. The model supports various communication protocols, ensuring seamless integration with other GE automation products and third-party devices. Additionally, it offers extensive I/O options, enabling it to connect with a wide range of sensors and actuators, making it versatile for numerous applications. The GE Fanuc also includes advanced diagnostic capabilities, helping technicians quickly identify and resolve issues, thus minimizing downtime.

Usage Scenarios:

The GE Fanuc is perfectly suited for diverse industrial applications. In manufacturing settings, it can be utilized for process automation, machine control, and data acquisition. Its robust design makes it ideal for harsh environments, including factories, oil and gas facilities, and power generation plants. Additionally, the GE Fanuc can integrate with existing systems, making it an excellent choice for companies looking to upgrade their automation processes without overhauling their entire infrastructure. Whether you’re controlling robotic arms on an assembly line or monitoring environmental conditions in a chemical processing plant, the GE Fanuc delivers reliability and performance.

Comparison with Other Models:

When comparing the GE Fanuc to other models in the GE lineup, such as the GE SR750 and GE IC697MDL740, the GE Fanuc excels in its processing capabilities and flexibility. While the GE SR750 is known for its high-speed performance, the GE Fanuc offers superior connectivity options and user-friendly interfaces, making it easier for operators to manage complex systems. In contrast to the GE IS200DSPXH2DBD, which focuses on specific applications, the GE Fanuc provides a broader range of functionalities, making it a more versatile choice for various industries.

Related Models:

For those considering the GE Fanuc, there are several related models worth exploring. The GE IC660BBA020 provides excellent data communication capabilities, while the GE DS200DDTBG2A offers robust control functions. The GE IS200JPDMG1ADC is ideal for motion control applications, whereas the GE IS200EDFFH1ABA is perfect for process control environments. Additionally, the GE IC200CPU005 and GE IC695CPE310-ABAH models are excellent alternatives for smaller-scale operations, offering compact designs without compromising performance. The GE VMIVME-7671-421000 and GE IC693ACC302 also provide valuable functionality for specific automation needs.

In summary, the GE Fanuc is a powerful and versatile solution for businesses seeking to enhance their automation capabilities. With its advanced technical features

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE Fanuc is equipped with an array of cutting-edge features that set it apart from competitors. It boasts high processing speeds, allowing for rapid data handling and control logic execution, essential for real-time applications. The model supports various communication protocols, ensuring seamless integration with other GE automation products and third-party devices. Additionally, it offers extensive I/O options, enabling it to connect with a wide range of sensors and actuators, making it versatile for numerous applications. The GE Fanuc also includes advanced diagnostic capabilities, helping technicians quickly identify and resolve issues, thus minimizing downtime.

Usage Scenarios:

The GE Fanuc is perfectly suited for diverse industrial applications. In manufacturing settings, it can be utilized for process automation, machine control, and data acquisition. Its robust design makes it ideal for harsh environments, including factories, oil and gas facilities, and power generation plants. Additionally, the GE Fanuc can integrate with existing systems, making it an excellent choice for companies looking to upgrade their automation processes without overhauling their entire infrastructure. Whether you’re controlling robotic arms on an assembly line or monitoring environmental conditions in a chemical processing plant, the GE Fanuc delivers reliability and performance.

Comparison with Other Models:

When comparing the GE Fanuc to other models in the GE lineup, such as the GE SR750 and GE IC697MDL740, the GE Fanuc excels in its processing capabilities and flexibility. While the GE SR750 is known for its high-speed performance, the GE Fanuc offers superior connectivity options and user-friendly interfaces, making it easier for operators to manage complex systems. In contrast to the GE IS200DSPXH2DBD, which focuses on specific applications, the GE Fanuc provides a broader range of functionalities, making it a more versatile choice for various industries.

Related Models:

For those considering the GE Fanuc, there are several related models worth exploring. The GE IC660BBA020 provides excellent data communication capabilities, while the GE DS200DDTBG2A offers robust control functions. The GE IS200JPDMG1ADC is ideal for motion control applications, whereas the GE IS200EDFFH1ABA is perfect for process control environments. Additionally, the GE IC200CPU005 and GE IC695CPE310-ABAH models are excellent alternatives for smaller-scale operations, offering compact designs without compromising performance. The GE VMIVME-7671-421000 and GE IC693ACC302 also provide valuable functionality for specific automation needs.

In summary, the GE Fanuc is a powerful and versatile solution for businesses seeking to enhance their automation capabilities. With its advanced technical features

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.