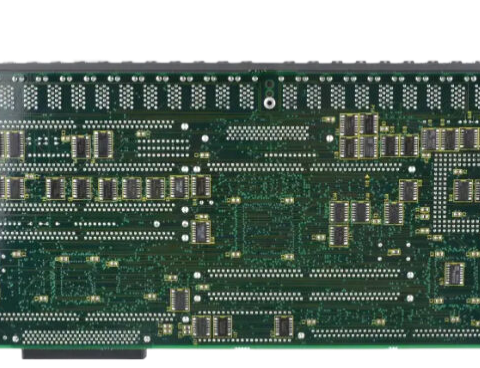

GE FANUC IC600CB527L Control Module Advanced Automation Solution

Introducing the GE FANUC, a pioneering solution in industrial automation that combines advanced technology, reliability, and efficiency. This model stands out in GE's extensive portfolio of automation products, designed to meet the demands of modern manufacturing and process control environments.

Key Technical Features

The GE FANUC offers a robust architecture built for high-performance applications. It features a powerful processor that ensures rapid data processing and seamless integration with existing systems. The modular design allows for easy expansion and customization, catering to specific operational needs. With advanced communication interfaces, the GE FANUC supports multiple protocols, making it compatible with a wide range of devices and systems. Its advanced diagnostics capabilities provide real-time monitoring and troubleshooting, significantly enhancing operational efficiency. Furthermore, the unit boasts a high degree of reliability, ensuring minimal downtime and maximum productivity.

Usage Scenarios

The versatility of the GE FANUC makes it suitable for various industries, including manufacturing, oil and gas, chemicals, and food processing. In manufacturing, for instance, it can control robotic arms, manage assembly lines, or optimize material handling systems. In the oil and gas sector, it can monitor and control drilling operations, ensuring safety and efficiency. Chemical plants benefit from its ability to monitor and control complex processes, adhering to strict compliance regulations. The GE FANUC is also ideal for upgrading legacy systems, enhancing operational capabilities without the need for a complete overhaul.

Comparison with Other Models

When compared to other GE automation products, such as the GE IS200TBCIH1BBC and GE IS220PAICH2A, the GE FANUC provides a more versatile solution with enhanced processing power and communication capabilities. While the IS200 series targets specific applications, the FANUC model excels in multi-faceted environments, making it a go-to choice for companies looking to future-proof their operations. Additionally, models like the GE IC697MDL250 and GE IS220PPROS1B focus on specific functions, whereas the GE FANUC integrates various functionalities into a single platform, offering a comprehensive solution.

Related Models

For organizations considering the GE FANUC, several related models can complement or enhance its functionality. The GE IS200TPROH1BBB and GE IS215UCVEH2AB provide additional processing capabilities for specialized applications. The GE IC670MDL640 and GE IC693CPU374 are excellent for organizations needing robust input/output processing. The GE DS200SDCCG1AGD and GE DS200CTBAG1ADD offer advanced communication and control options that can be integrated with the GE FANUC for more complex automation tasks. The GE IS230SNIDH1A and GE IC698CMX016 also enrich the automation landscape, providing options for specific operational needs.

Conclusion

The GE FANUC is not just another product in the GE automation family; it is a transformative solution designed to optimize operational efficiency across various industries. Its key technical features, versatility in usage scenarios, and superior performance compared to other models make it an essential component for any modern industrial operation. With its capability to integrate seamlessly into existing systems and its compatibility with a wide range of devices, the GE FANUC stands out as a leader in automation technology. For businesses looking to enhance their operational capabilities, investing in the GE FANUC is a strategic choice that promises to deliver long-term benefits. Explore the future of automation with the GE FANUC, where innovation meets reliability in every application.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE FANUC offers a robust architecture built for high-performance applications. It features a powerful processor that ensures rapid data processing and seamless integration with existing systems. The modular design allows for easy expansion and customization, catering to specific operational needs. With advanced communication interfaces, the GE FANUC supports multiple protocols, making it compatible with a wide range of devices and systems. Its advanced diagnostics capabilities provide real-time monitoring and troubleshooting, significantly enhancing operational efficiency. Furthermore, the unit boasts a high degree of reliability, ensuring minimal downtime and maximum productivity.

Usage Scenarios

The versatility of the GE FANUC makes it suitable for various industries, including manufacturing, oil and gas, chemicals, and food processing. In manufacturing, for instance, it can control robotic arms, manage assembly lines, or optimize material handling systems. In the oil and gas sector, it can monitor and control drilling operations, ensuring safety and efficiency. Chemical plants benefit from its ability to monitor and control complex processes, adhering to strict compliance regulations. The GE FANUC is also ideal for upgrading legacy systems, enhancing operational capabilities without the need for a complete overhaul.

Comparison with Other Models

When compared to other GE automation products, such as the GE IS200TBCIH1BBC and GE IS220PAICH2A, the GE FANUC provides a more versatile solution with enhanced processing power and communication capabilities. While the IS200 series targets specific applications, the FANUC model excels in multi-faceted environments, making it a go-to choice for companies looking to future-proof their operations. Additionally, models like the GE IC697MDL250 and GE IS220PPROS1B focus on specific functions, whereas the GE FANUC integrates various functionalities into a single platform, offering a comprehensive solution.

Related Models

For organizations considering the GE FANUC, several related models can complement or enhance its functionality. The GE IS200TPROH1BBB and GE IS215UCVEH2AB provide additional processing capabilities for specialized applications. The GE IC670MDL640 and GE IC693CPU374 are excellent for organizations needing robust input/output processing. The GE DS200SDCCG1AGD and GE DS200CTBAG1ADD offer advanced communication and control options that can be integrated with the GE FANUC for more complex automation tasks. The GE IS230SNIDH1A and GE IC698CMX016 also enrich the automation landscape, providing options for specific operational needs.

Conclusion

The GE FANUC is not just another product in the GE automation family; it is a transformative solution designed to optimize operational efficiency across various industries. Its key technical features, versatility in usage scenarios, and superior performance compared to other models make it an essential component for any modern industrial operation. With its capability to integrate seamlessly into existing systems and its compatibility with a wide range of devices, the GE FANUC stands out as a leader in automation technology. For businesses looking to enhance their operational capabilities, investing in the GE FANUC is a strategic choice that promises to deliver long-term benefits. Explore the future of automation with the GE FANUC, where innovation meets reliability in every application.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.